Inorganic-machining vacuum evanescent mode cast telescopic gate valve

A vacuum lost foam and inorganic technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of different effects and achieve the effects of simplifying the construction process, reducing waste and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

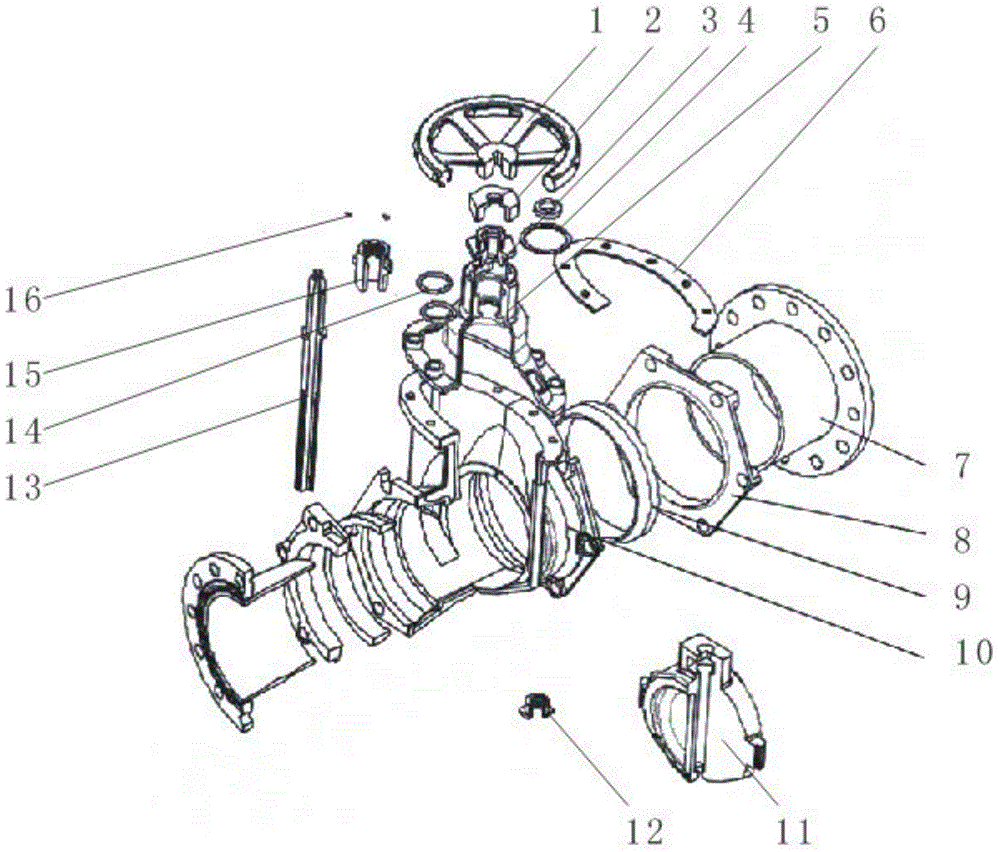

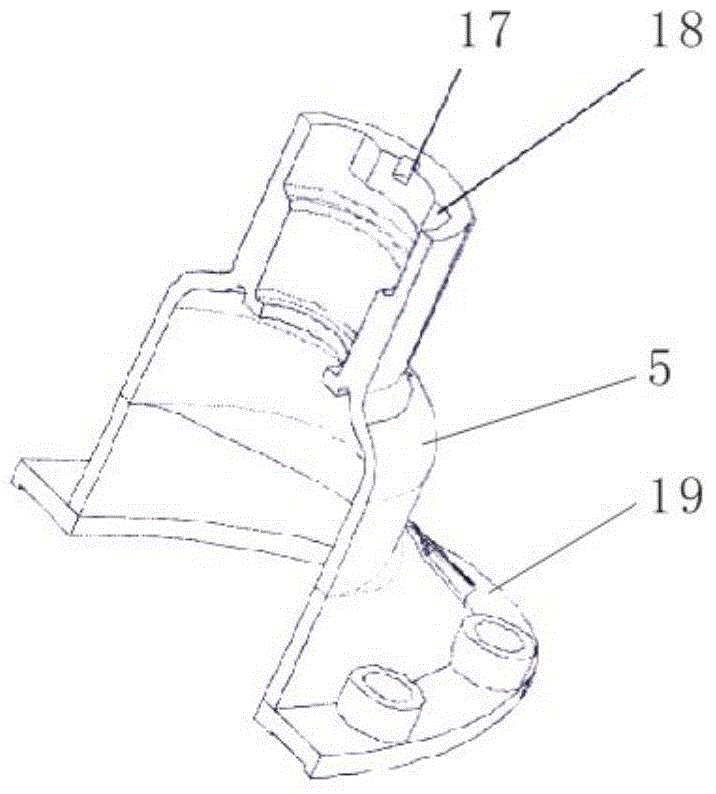

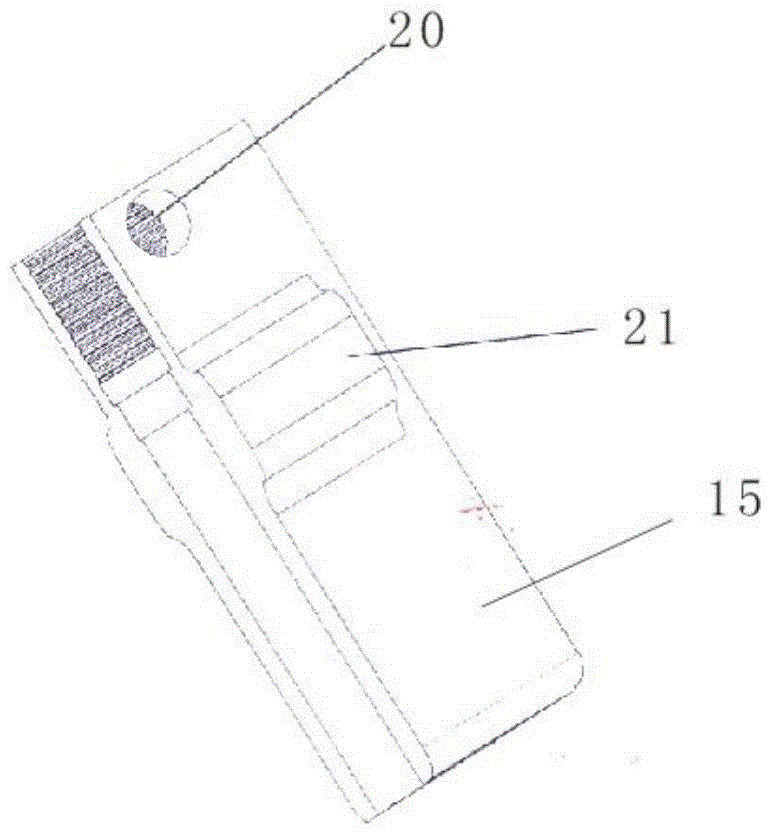

[0026] An inorganic processing vacuum lost foam casting telescopic gate valve, including a valve body 10, a valve cover 5, a gate plate 11, a valve stem 13, a lock nut 15, a middle joint nut 3, a pressure nut 2, an expansion joint 7 and a pressure ring flange 8 ,

[0027] For the specific structure of the valve made in this embodiment, refer to the accompanying drawings of the description, and for the convenience of description, the attached figure 1 The direction shown in , the upper end of the valve body 10 is sealed and fixed with the bonnet 5, and a transverse flow channel is formed in the valve body, and a gate 11 for cutting the flow channel is installed in the middle of the valve body. The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com