Silica sol slow seepage reinforcement method for argillaceous soft rock

A silica sol and soft rock technology, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve problems such as large deformation support, improve the compactness, increase the deformation resistance and durability of rock mass, and reduce penetration. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the silica sol slow seepage reinforcement method of argillaceous soft rock of the present invention, concrete steps are as follows:

[0020] A roadway with a rectangular section, width × height = 4.6 × 3.6m, the roof is siltstone, rich in fissure water; the sides and floor are mudstone, and when it is cemented, micropores develop. In order to control the large deformation of the roadway, silica sol is used for grouting, and silica sol A material: B material = 4:1.

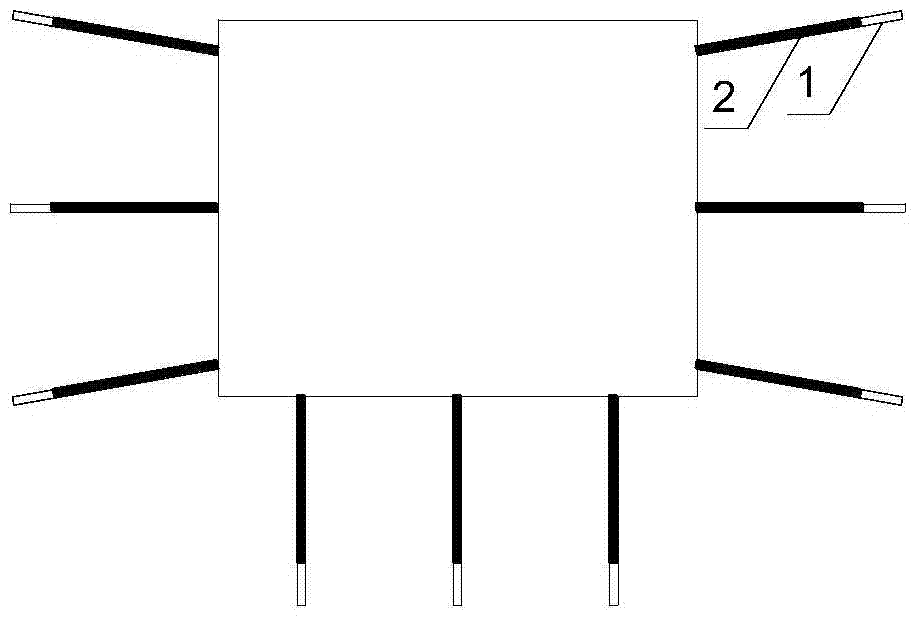

[0021] Construct grouting hole 1 on the side and floor before mudification, with a depth of 2m and a row spacing of 1.5m; install grouting pipe 2 and seal the hole, and inject silica sol; when the grouting pressure reaches 1.5MPa, stabilize the pressure for 5min Finally, reduce the grouting pressure, during which, driven by the grouting pressure, the silica sol quickly fills and strengthens the macroscopic cracks;

[0022] When the grouting pressure drops to 0.5MPa, the grouting is stopped aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com