Assembled inclined pile foundation for offshore wind turbines

An offshore wind turbine and prefabricated technology, applied in the field of pile foundation structure, can solve the problems of long maintenance time, high cost, long construction period, etc., to reduce construction risks and difficulties, the foundation form is concise and clear, and has good stability and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

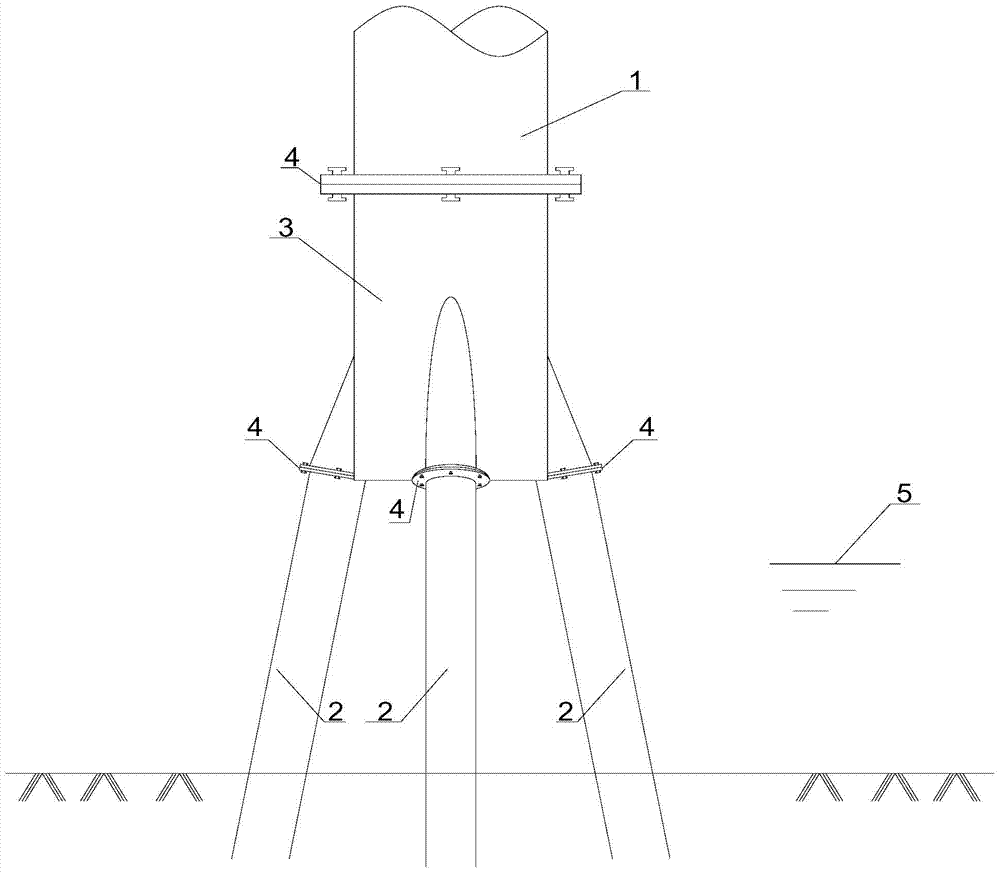

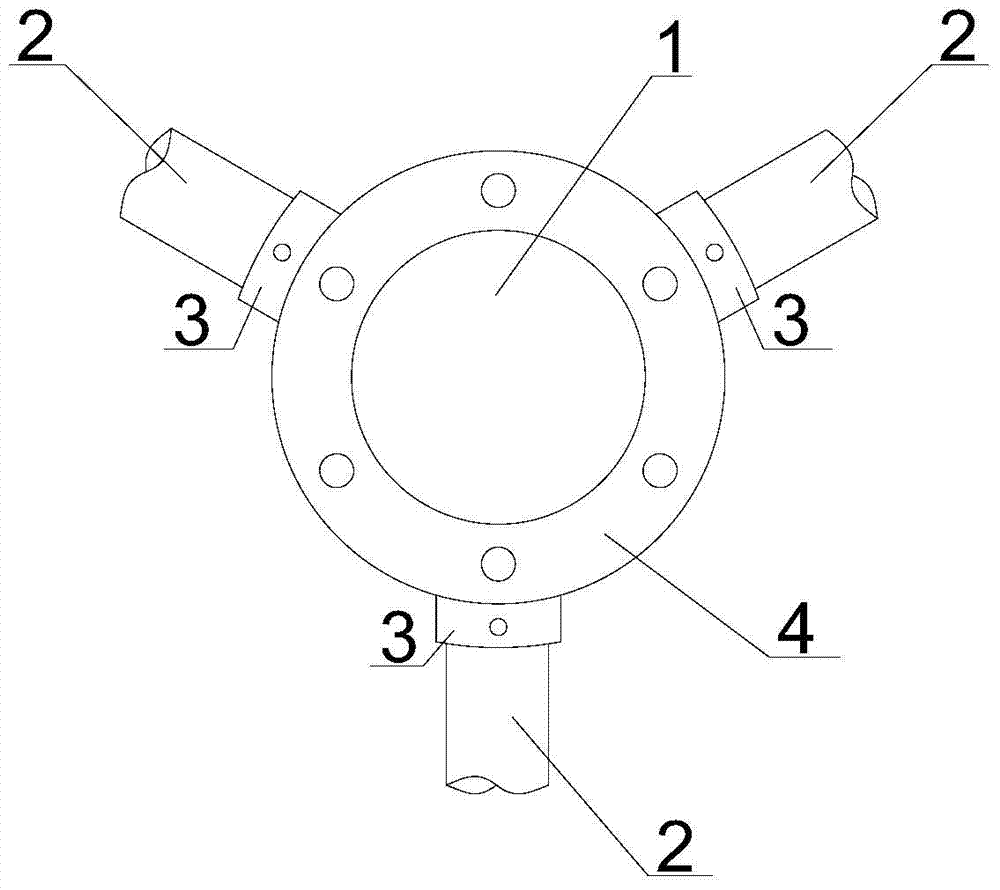

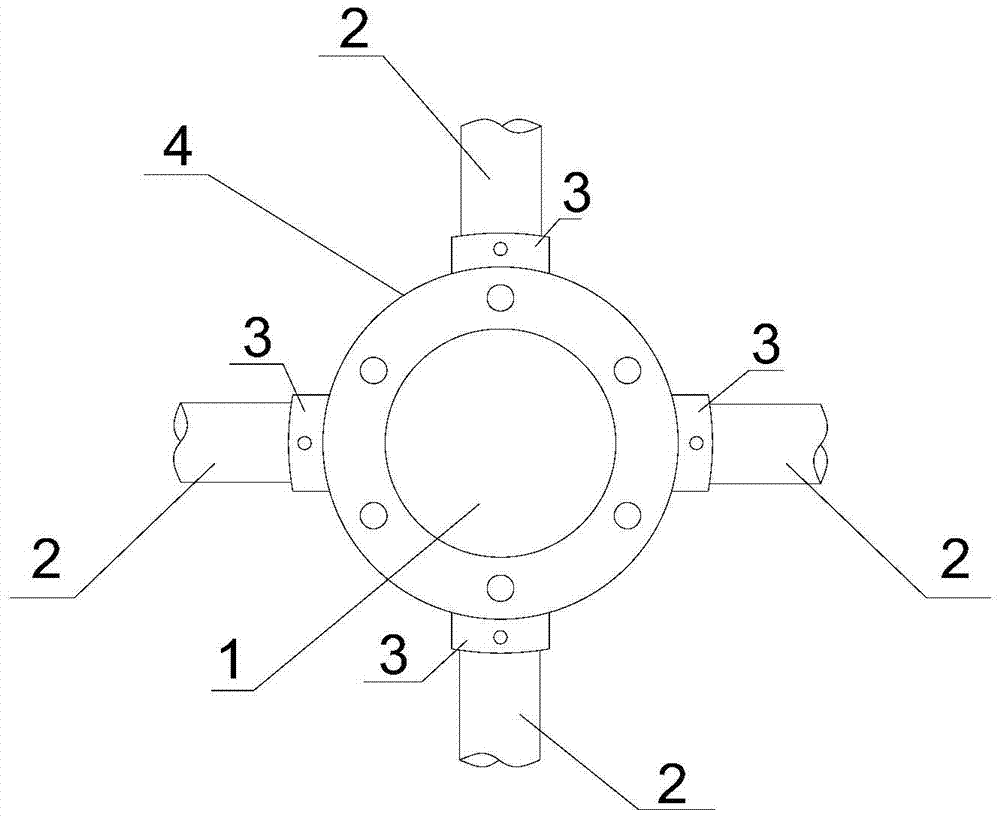

[0029] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a wind turbine tower 1, a steel pile foundation 2 and a conversion steel structure 3 connected between the steel pile foundation 2 and the wind turbine tower 1, the steel pile foundation 2 is installed obliquely to the wind turbine tower 1, and the wind turbine tower 1. The steel pile foundation 2 is connected to the transfer steel structure 3 through flanges 4 respectively.

[0030] Such as figure 1 , figure 2 and image 3 As shown, the conversion steel structure 3 is a branch-shaped structure including a central tube and multiple branches around the central tube. The flange plate 4 is coaxially connected with the bottom end of the fan tower 1 .

[0031] Such as figure 1 As shown, when the number of piles is three or four, the side wall of the convert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com