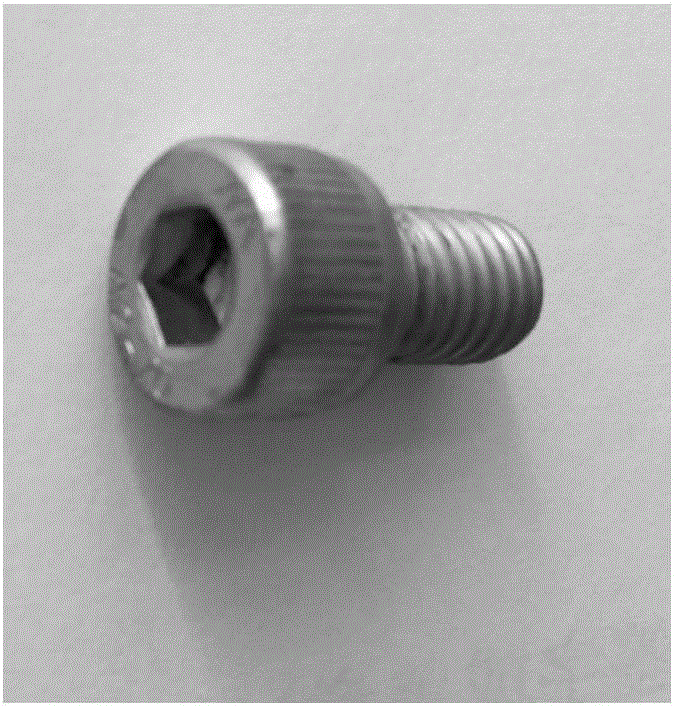

Bolt electroplating pretreatment method

A technology of pretreatment and bolts, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve problems such as poor pretreatment effect, and achieve smooth and beautiful workpiece surface, high economic benefits, and easy operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take the bolts to be treated and put them into the electrolyte, turn on the electricity and electrolyze, and degrease and degrease the bolt matrix. Then, the degreased bolts are put into dilute hydrochloric acid, and the oxides on the surface of the bolt matrix are removed by pickling. After pickling, put it in ethanol, ultrasonically clean it, and dry it. The ionic liquid of aluminum oxide and disubstituted imidazolium chloride with a molar ratio of 2:1 is used as the activation solution, the bolt workpiece is used as the anode, and the Al plate is used as the cathode. 2 The current density is used for activation, and the activation time is 6 minutes.

[0042] Further, during the activation process, the activation solution is stirred to promote the disturbance of the ionic liquid on the surface of the workpiece, so that the oxide layer is completely removed during the anodic activation process, and the stirring rate is 200r / min.

Embodiment 2

[0044] Get the bolts to be treated and put them into the electrolyte solution: sodium hydroxide 40g / L, sodium carbonate 30g / L, trisodium phosphate 10g / L. , heated to 65°C, energized and electrolyzed for 1 minute, with a current density of 4mA / cm 2 , Degreasing and degreasing. Then, put the degreased bolts into dilute nitric acid, soak and pickle for 30 seconds to remove the oxides on the surface. After pickling, put it into propanol, set the ultrasonic instrument to 100W, ultrasonically clean for 15min, and dry. The ionic liquid of aluminum oxide and disubstituted imidazolium chloride with a molar ratio of 3:1 is used as the activation solution, the bolt workpiece is used as the anode, and the Al plate is used as the cathode. 2 The current density is used for activation, and the activation time is 8 minutes.

Embodiment 3

[0046] This embodiment is used to illustrate the bolt electroplating pretreatment method provided by the present invention.

[0047] The experimental material is high-strength bolts, and the specific operation steps are as follows:

[0048] (1) One-step oil removal, the oil removal solution formula is: sodium hydroxide 30g / L, sodium carbonate 30g / L, trisodium phosphate 5g / L and the balance deionized water. Except for ionized water, other components are dissolved in deionized water according to the proportion of the formula, and mixed to obtain an aqueous solution, which is put into a tank for use. Put the high-strength bolt workpiece as the cathode, and the 304 stainless steel plate as the anode, put it into the electrolyte at a temperature of 60°C, and apply a current density of 5mA / cm 2 , electrolytic degreasing 1min.

[0049] (2) Pickling, pickling solution formula: 5% dilute hydrochloric acid. Immerse the electrolytically degreased high-strength bolt workpiece in the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com