Low-melting-point mixed molten salt heat transfer and thermal storage working medium and application thereof

A technology of mixing molten salt and low melting point, used in heat exchange materials, chemical instruments and methods, etc., can solve the problems of high melting point of molten salt, unable to meet the needs of melting point of heat transfer working medium, etc. The effect of stable physical properties and good heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

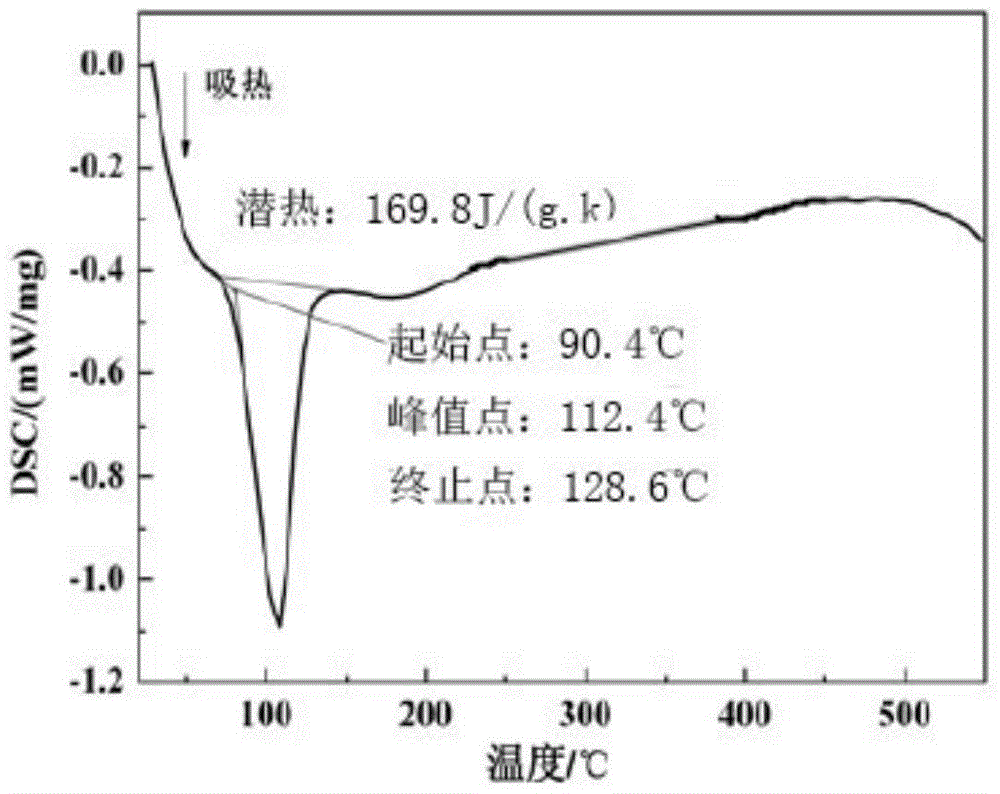

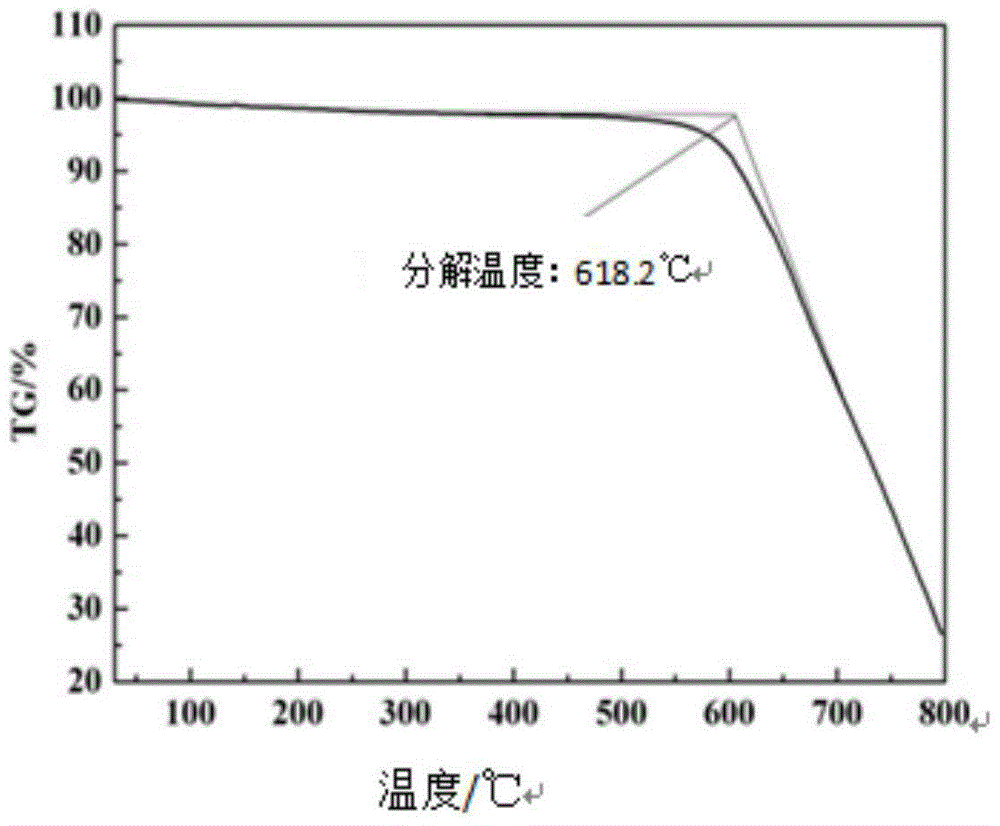

[0018] Embodiment: a kind of low melting point mixed molten salt heat transfer heat storage working medium, is made of Ca(NO 3 ) 2 4H 2 O. KNO 3 、NaNO 3 、LiNO 3 and Na 2 CO 3 Composition, its mass ratio is: Ca(NO 3 ) 2 4H 2 O: 16-27wt%; KNO 3 : 49-57wt%; NaNO 3 : 5-13wt%; LiNO 3 : 6-12wt%; Na 2 CO 3 : 4-11wt%.

[0019] A preparation method of a low melting point mixed molten salt heat transfer and heat storage working medium is as follows:

[0020] (1) First mix the Ca(NO 3 ) 2 4H 2 O. KNO 3 、NaNO 3 、LiNO 3 and Na 2 CO 3 The materials are crushed and ground separately, so that the diameter of the solid particles is less than 3cm, and the materials are put into stainless steel containers in proportion, and mixed and stirred;

[0021] (2) Gradually heat the mixed molten salt, while stirring continuously to about 120°C and keep it for 10 minutes, and evaporate the water in the mixed molten salt;

[0022] (3) Continue to heat up to about 200°C and maintain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com