Environment-friendly separant for rubber film, separant solution and separant coating process

A coating process and release agent technology, which is applied to coatings, wax coatings, and devices for coating liquids on surfaces, etc., can solve the problem of poor apparent quality of rubber products, uneven coating of talc powder, and physical injuries to operators. and other problems, to achieve the effect of good covering power, no impact on performance, and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The environment-friendly release agent for rubber film of this embodiment is characterized in that: in parts by mass, the composition and proportioning are: 40-50 parts of zinc stearate, 35-45 parts of talcum powder and 10-20 parts of paraffin oil . The talcum powder is 1250 mesh; the paraffin oil grade is TUDALEN16, and the paraffin oil has the advantages of colorless, odorless and good compatibility with rubber.

[0026] The release agent solution is prepared by the release agent and water in a ratio of 1:20 to 1:25 in parts by mass; the composition and proportion of the release agent in parts by mass are: 40-50 parts of zinc stearate, 35 parts of talc -45 parts and 10-20 parts of paraffin oil.

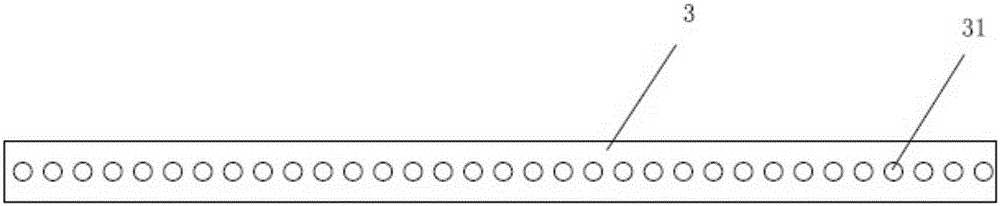

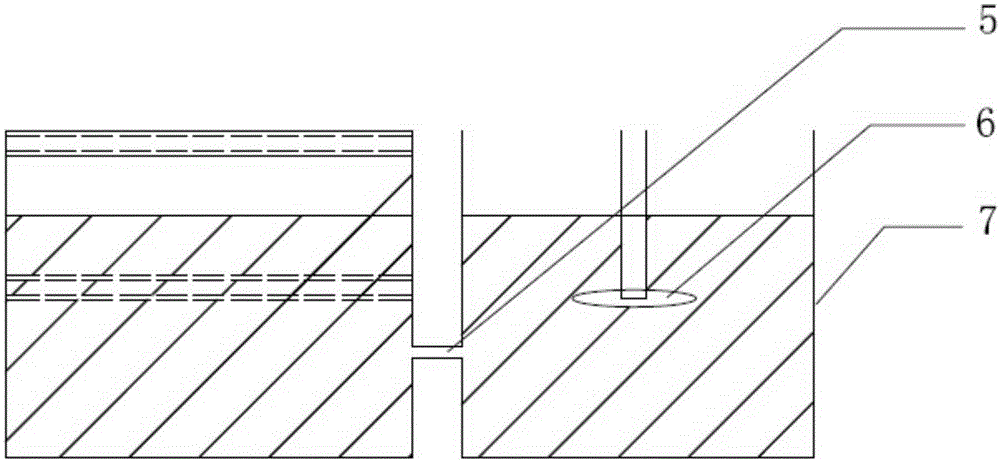

[0027] Rubber film release agent coating process includes the following steps:

[0028] Step 1: Prepare the release agent solution: the release agent solution is prepared by the release agent and water in a ratio of 1:20 to 1:25 in parts by mass; the composition and ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com