Phenolic foam heat insulation board of core-shell structure and preparing method thereof

A technology of foam insulation board and core-shell structure, applied in the field of phenolic foam insulation board and its preparation, can solve the problems of low toughness and easy breakage of phenolic foam, improve water absorption and comprehensive performance, reduce the possibility of fracture, and improve thermal conductivity. The effect of coefficient reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Add phenol, paraformaldehyde, and sodium hydroxide to the reaction kettle at a mass ratio of 65:30:1, add solid paraformaldehyde in batches at a water bath temperature of 60°C, control the addition for half an hour, and continue the reaction for half an hour hours, raise the temperature to 90°C, and continue the reaction for 1.5 hours to obtain the phenolic resin. Take 100.0 parts of phenolic resin, 6.0 parts of surfactant, 15 parts of foaming agent n-pentane, 15 parts of curing agent, and 1 part of nucleating agent, mix and stir evenly for use.

[0037] (2) Take 100 parts of polyethylene adipate diol (PEA2000), 10 parts of toluene diisocyanate (TDI-80), and 0.1 part of dibutyltin dilaurate (DBTDL) into the reaction kettle, 80 ℃ Under vacuum reaction for 1h, the polyurethane prepolymer was obtained. Take 100 parts of polyurethane prepolymer, 2 parts of foam stabilizer, and 12 parts of foaming agent, mix and stir evenly for use.

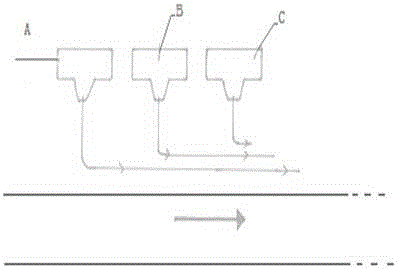

[0038] (3) Reaction kettles A and ...

Embodiment 2

[0040](1) Add phenol, paraformaldehyde, and sodium hydroxide to the reaction kettle at a mass ratio of 65:35:1, add solid paraformaldehyde in batches at a water bath temperature of 60°C, control the addition for half an hour, and continue the reaction for half an hour hours, raise the temperature to 90°C, and continue to react

[0041] It should take 1.5 hours to obtain phenolic resin. Take 100.0 parts of phenolic resin, 6.0 parts of surfactant, 15 parts of foaming agent n-pentane, 15 parts of curing agent, and 1 part of nucleating agent, mix and stir evenly for use.

[0042] (2) Take 100 parts of polyethylene adipate diol (PEA2000), 10 parts of toluene diisocyanate (TDI-80), and 0.1 part of dibutyltin dilaurate (DBTDL) into the reaction kettle, 80 ℃ Under vacuum reaction for 1h, the polyurethane prepolymer was obtained. Take 100 parts of polyurethane prepolymer, 2 parts of foam stabilizer, and 12 parts of foaming agent, mix and stir evenly for use.

[0043] (3) Same as ste...

Embodiment 3

[0045] (1) Add phenol, paraformaldehyde, and sodium hydroxide to the reaction kettle at a mass ratio of 65:40:1, add solid paraformaldehyde in batches at a water bath temperature of 60°C, control the addition for half an hour, and continue the reaction for half an hour hours, raise the temperature to 90°C, and continue the reaction for 1.5 hours to obtain the phenolic resin. Take 100.0 parts of phenolic resin, 6.0 parts of surfactant, 15 parts of foaming agent n-pentane, 15 parts of curing agent, and 1 part of nucleating agent, mix and stir evenly for use.

[0046] (2) Take 100 parts of polyethylene adipate diol (PEA2000), 10 parts of toluene diisocyanate (TDI-80), and 0.1 part of dibutyltin dilaurate (DBTDL) into the reaction kettle, 80 ℃ Under vacuum reaction for 1h, the polyurethane prepolymer was obtained. Take 100 parts of polyurethane prepolymer, 2 parts of foam stabilizer, and 12 parts of foaming agent, mix and stir evenly for use.

[0047] (3) Same as step 3 of Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com