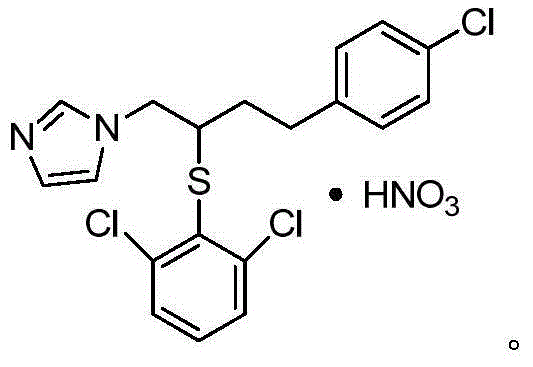

Method for industrially producing butoconazole nitrate intermediate

A kind of technology of butconazole nitrate and intermediate, which is applied in the production field of 1-chloro-4--2-butanol as the intermediate of butconazole nitrate, and can solve the complex production process of butconazole nitrate, product yield and purity. It can not meet the problems of industrial production and high cost, and achieve the effect of being suitable for large-scale industrial production, reasonable raw materials and dosage, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

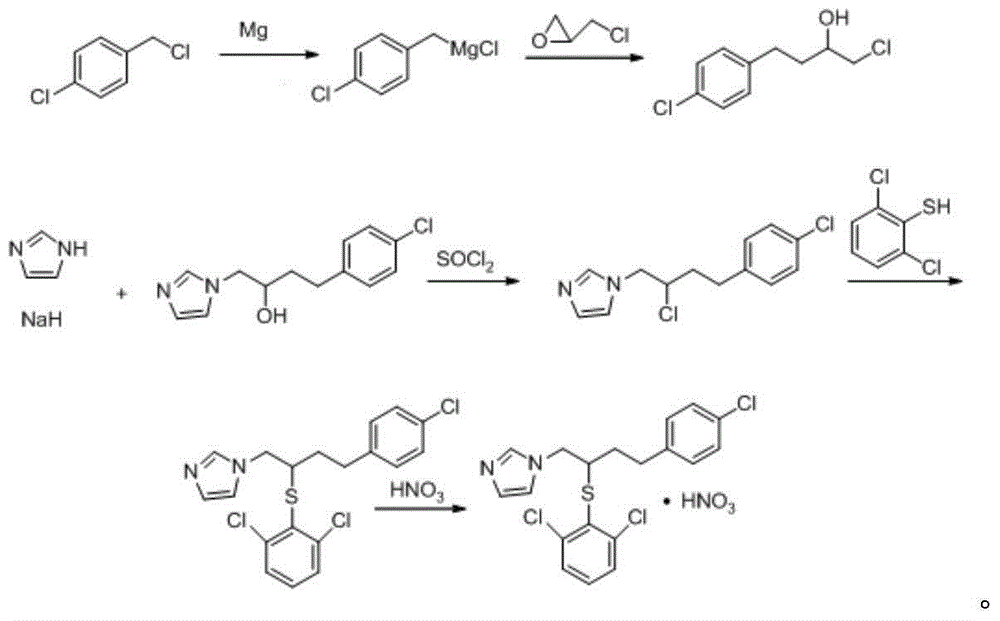

Method used

Image

Examples

Embodiment 1

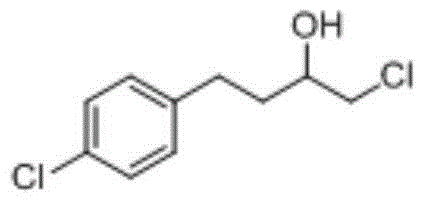

[0037] Prepare butoconazole nitrate intermediate 1-chloro-4-(4-chlorophenyl)-2-butanol as follows:

[0038] (1) Get 2.5kg of magnesium powder, 50ml of ether and a catalytic amount of iodine, add 40kg of p-chlorobenzyl ether solution with a concentration of 0.28g / ml dropwise at a rate of 3ml / s at 35°C, and after the dripping, add it at 38°C React for 1 hour to obtain p-chlorobenzyl Grignard reagent; then slowly add 20 kg of epichlorohydrin ether solution with a concentration of 0.35 g / ml dropwise, and react at 38° C. for 1.5 hours after dropping to obtain a reaction solution;

[0039] (2) Take the reaction solution obtained in step (1), add the sulfuric acid with a concentration of 25% dropwise at a rate of 2ml / s at 4°C under constant stirring, and stop the dripping when there is no solid residue; leave standstill after stirring at a constant speed for 10min The liquid was separated for 10 minutes; the aqueous phase was discarded, and the organic phase was concentrated at -0.01...

Embodiment 2

[0042] Compared with Example 1, the difference is only that the step (2) is specifically:

[0043] Get the reaction solution gained in step (1), add the sulfuric acid with a concentration of 24% dropwise at a rate of 1ml / s at 0°C under constant stirring, stop the dropwise addition when there is no solid residue; leave standstill for 8 minutes after stirring at a constant speed for 5 minutes to make the liquid Separate the layers; discard the water phase, take the organic phase and concentrate it at -0.05MPa, 50°C until no diethyl ether evaporates, collect the fraction at 160-180°C / 10mmHg by rectification, dry it, and obtain it.

[0044] The yield of the product of this embodiment is 77.4%.

[0045] After testing, the content of the target product 1-chloro-4-(4-chlorophenyl)-2-butanol is 90.27%, the content of p-chlorotoluene is 5.53%, and the content of chloromethylbenzene is 0.41%, 1, The content of 2-(4-chlorophenyl)ethane is 1.83%, the content of 1-chloro-4-(4-(chloro)benz...

Embodiment 3

[0047] Compared with Example 1, the difference is only that the step (2) is specifically:

[0048] (2) Get the reaction solution obtained in step (1), add the sulfuric acid with a concentration of 26% dropwise at a rate of 3ml / s at 10°C under constant stirring, and stop the dripping when there is no solid residue; leave standstill after stirring at a constant speed for 15min The liquid was separated for 12 minutes; the water phase was discarded, and the organic phase was concentrated at 0 MPa and 60°C until no ether evaporated, and the fraction at 160-180°C / 10mmHg was collected by rectification, and dried to obtain the product.

[0049] The yield of the product of this embodiment is 73.3%.

[0050] After testing, the content of the target product 1-chloro-4-(4-chlorophenyl)-2-butanol is 85.14%, the content of p-chlorotoluene is 10.47%, and the content of chloromethylbenzene is 0.43%, 1, The content of 2-(4-chlorophenyl)ethane was 1.81%, the content of 1-chloro-4-(4-(chloro)be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com