An escalator truss without welding encapsulation structure

A technology without welding and escalators, applied in escalators, transportation and packaging, etc., can solve the problems of weakened bearing capacity of the original truss, large deformation, brittle original truss material, etc., and achieve the effect of strengthening the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

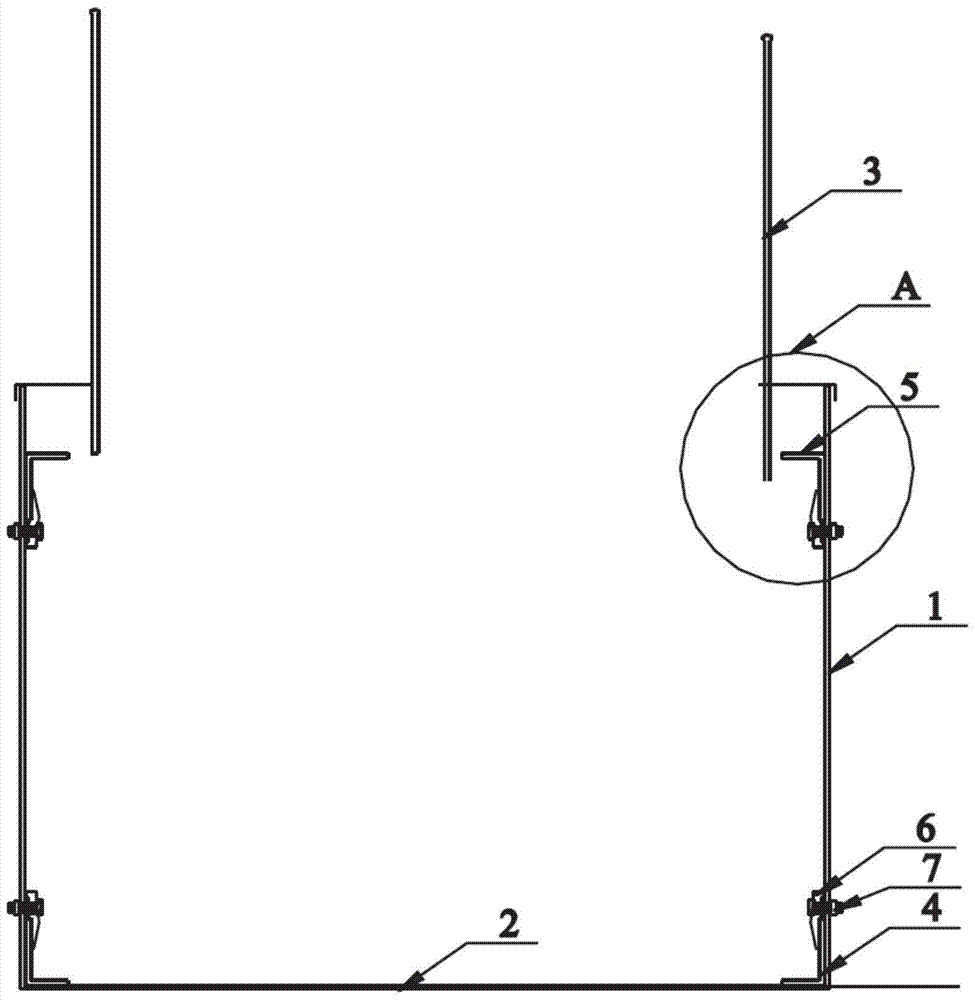

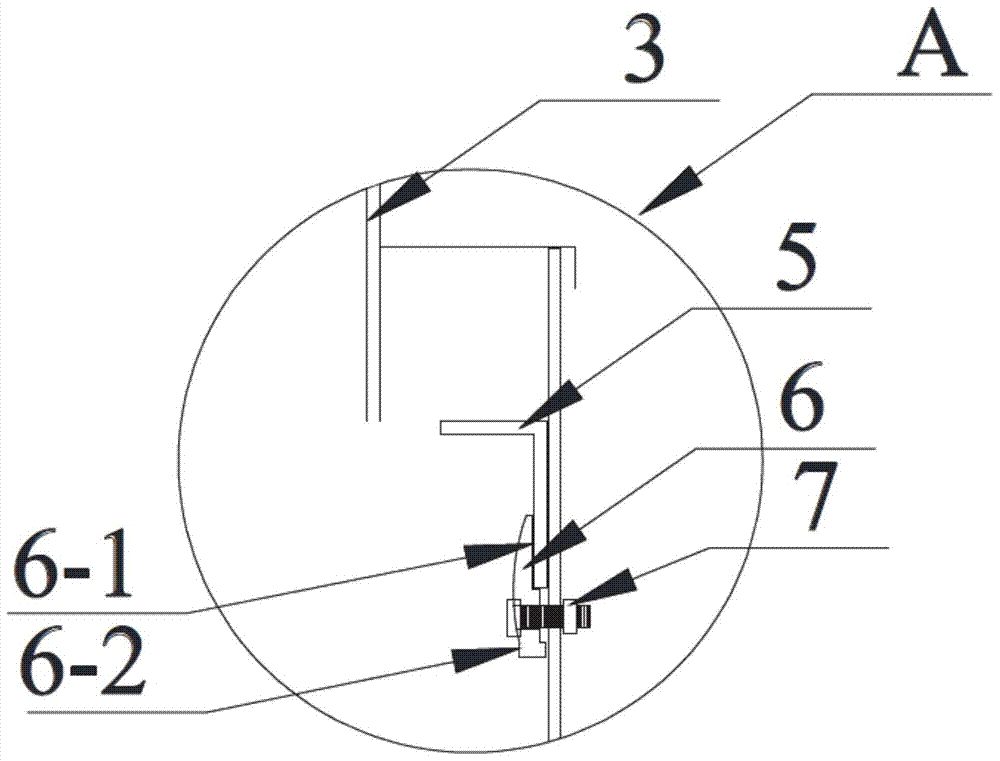

[0028] as attached figure 1 , 2 Shown: the present invention is a welding-free encapsulation structure of an escalator truss, the non-welding encapsulation structure includes a steel plate fixing part 1 arranged between the escalator bottom plate 2 and the escalator cover plate 3, and the steel plate fixing part 1 The lower end and the upper part are respectively provided with an escalator floor support 4 and an escalator cover support 5, and the escalator floor support 4 and the escalator cover support 5 are pressed on the steel plate fixing part 1 by pressing blocks 6 respectively. Block 6 is connected with steel plate fixing part 1 by bolt 7, and described escalator floor support part 4 and escalator cover plate support part 5 are respectively the lower beam and the upper beam of the escalator truss, and the steel plate fixing part 1 is also connected with the escalator Decorative plates.

[0029] A preferred embodiment of the present invention is that the steel plate fix...

Embodiment 2

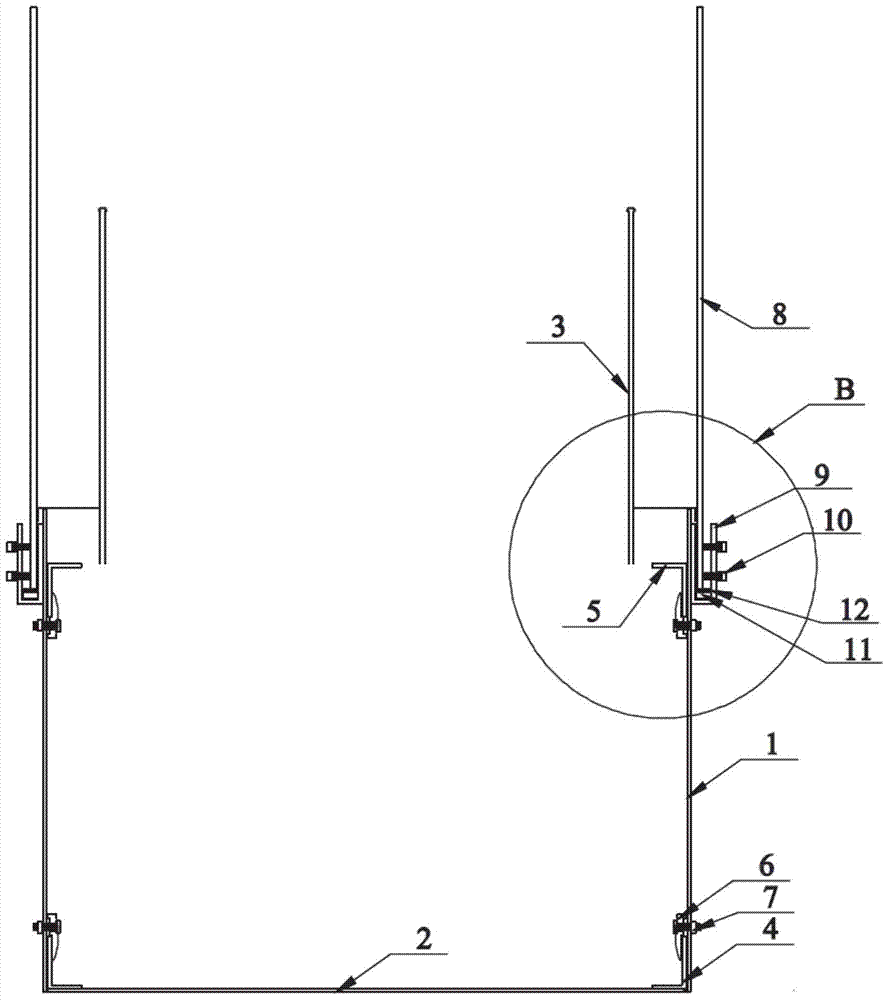

[0035] as attached image 3 , 4 Shown: the present invention is a welding-free encapsulation structure of an escalator truss, the non-welding encapsulation structure includes a steel plate fixing part 1 arranged between the escalator bottom plate 2 and the escalator cover plate 3, and the steel plate fixing part 1 The lower end and the upper part are respectively provided with an escalator floor support 4 and an escalator cover support 5, and the escalator floor support 4 and the escalator cover support 5 are pressed on the steel plate fixing part 1 by pressing blocks 6 respectively. Block 6 is connected with steel plate fixing part 1 by bolt 7, and described escalator floor support part 4 and escalator cover plate support part 5 are respectively the lower beam and the upper beam of the escalator truss, and the steel plate fixing part 1 is also connected with the escalator Decorative plates.

[0036] A preferred embodiment of the present invention is that the steel plate fix...

Embodiment 3

[0043] as attached Figure 5 , 6, 7: the present invention is a non-welding encapsulation structure of an escalator truss, the non-welding encapsulation structure includes a steel plate fixing part 1 arranged between the escalator bottom plate 2 and the escalator cover plate 3, and the steel plate fixing part The lower end and the upper part of 1 are respectively provided with an escalator floor support 4 and an escalator cover support 5, and the escalator floor support 4 and the escalator cover support 5 are respectively pressed on the steel plate fixing member 1 by a pressure block 6, so that The briquetting block 6 is connected with the steel plate fixing part 1 through the bolt 7, and the escalator floor support part 4 and the escalator cover plate support part 5 are respectively the lower beam and the upper beam of the escalator truss, and the steel plate fixing part 1 is also connected with Decorative panels for escalators.

[0044] A preferred embodiment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com