Vehicle body structure and method for improving outside corridor locomotive modal frequency

A technology of modal frequency and car body structure, applied in the direction of railway car body, railway car body parts, transportation and packaging, etc., can solve the problem of low frequency of first-order sagging mode, and achieve enhanced stability and torsional performance , Simple structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

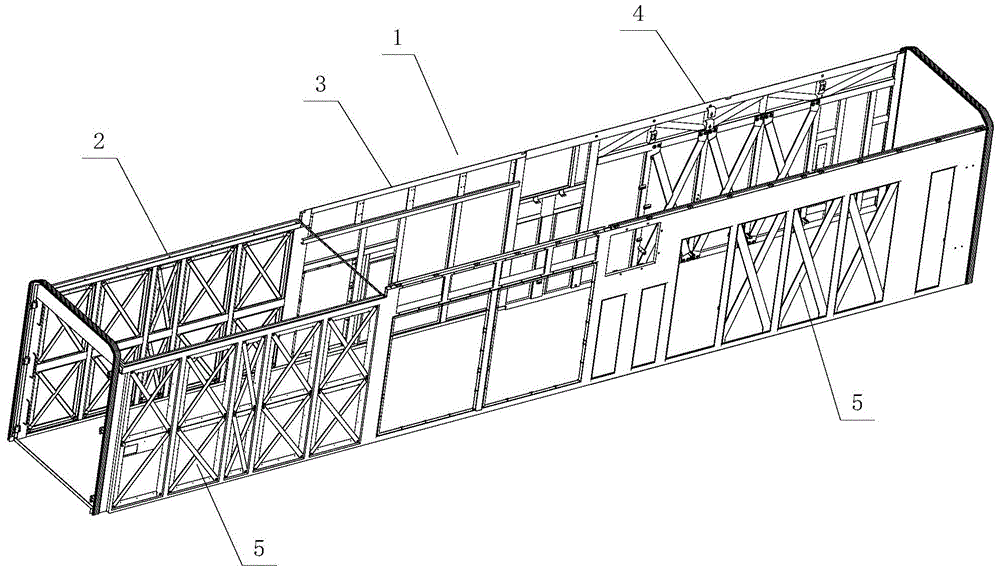

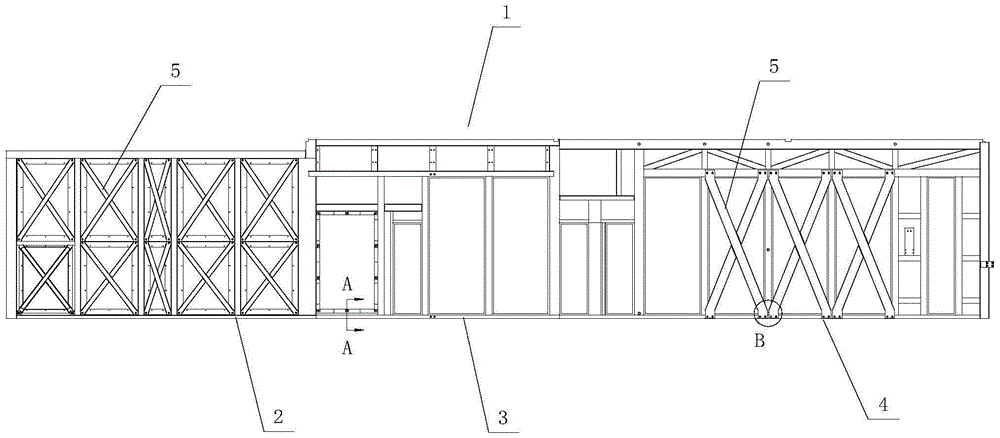

[0027] see Figure 1 to Figure 6 As shown, a car body structure for improving the modal frequency of an outer corridor locomotive includes a car body and a side wall frame 1, and the side wall frame 1 is welded and fixed on the car body. The side wall frame 1 is sequentially from left to right a battery room frame 2 , an electrical room frame 3 and a power room frame 4 , and a cross bracing structure 5 is installed on the sides of the battery room frame 2 and the power room frame 4 .

[0028] Both sides of the battery room frame 2 are two rows of rectangular frames 21 , each row of five rectangular frames 21 , and a cross bracing structure 5 is installed in each rectangular frame 21 .

[0029] Both sides of the power chamber frame 4 are respectively a row of three rectangular frames 41 , and a cross bracing structure 5 is installed in each rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com