Temperature-resistant shallow stretch film and production method thereof

A production method and technology of stretching film, which are applied in chemical instruments and methods, layered products, other household appliances, etc., can solve the problems of easy distortion of appearance, small stretchability, poor temperature resistance, etc., to solve wrinkling, improve Good stiffness and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

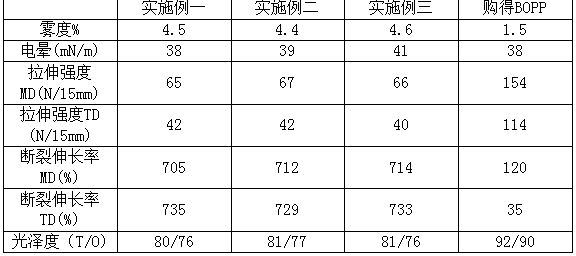

Embodiment 1

[0014] The production method of the temperature-resistant shallow stretch film includes the following steps: (1) Adding materials, the lower layer is composed of 100% homopolymerized PP, the inner layer is composed of 97.1 parts by weight of homopolymerized PP, and 0.1 parts by weight of β crystal nucleation agent (TMB-5), 0.8 parts by weight of slip agent (GL5068PPR) and 2 parts by weight of ema plastic (1820AC), the surface layer is composed of 95.1 parts by weight of homopolymer PP, 0.1 parts by weight of β crystal nucleating agent ( TMB-5), 1 part by weight of PPR organic release agent (AB6064), 1 part by weight of silicone, 1 part by weight of poly-4-methyl-1-pentene (MX002), 1.5 parts by weight of cyclic poly Olefin (790R), 0.3 parts by weight of ethylene-α-octene copolymer; the materials of the mixed lower layer, inner layer and surface layer are respectively added to the three barrels of the co-extruder;

[0015] (2) Heating. The materials in the three barrels of the c...

Embodiment 2

[0020] The production method of the temperature-resistant shallow stretch film includes the following steps: (1) Adding materials, the lower layer is composed of 100% homopolymerized PP, the inner layer is composed of 93.2 parts by weight of homopolymerized PP, and 0.3 parts by weight of β crystal nucleation agent (TMB-5), 1.5 parts by weight of slip agent (GL5068PPR) and 5 parts by weight of ema plastic (1820AC), the surface layer is composed of 85.5 parts by weight of homopolymerized PP, 0.3 parts by weight of β crystal nucleating agent ( TMB-5), 5 parts by weight of PPR organic release agent (AB6064), 3 parts by weight of silicone, 2.3 parts by weight of poly-4-methyl-1-pentene (MX002), 2.9 parts by weight of cyclic poly Olefin (790R), 1 weight part of ethylene-α-octene copolymer; add the mixed lower layer, inner layer and surface layer materials into the three barrels of the co-extruder respectively;

[0021] (2) Heating. The materials in the three barrels of the co-extrud...

Embodiment 3

[0026] The production method of the temperature-resistant shallow stretch film includes the following steps: (1) Adding materials, the lower layer is composed of 100% homopolymerized PP, the inner layer is composed of 95.8 parts by weight of homopolymerized PP, and 0.2 parts by weight of β crystal nucleation agent (TMB-5), 1.0 parts by weight of slip agent (GL5068PPR) and 3 parts by weight of ema plastic (1820AC), the surface layer is composed of 90.5 parts by weight of homopolymer PP, 0.2 parts by weight of β crystal nucleating agent ( TMB-5), 3 parts by weight of PPR organic release agent (AB6064), 2 parts by weight of silicone, 1.5 parts by weight of poly-4-methyl-1-pentene (MX002), 2.0 parts by weight of cyclic poly Olefin (790R), 0.8 parts by weight of ethylene-α-octene copolymer; the materials of the mixed lower layer, inner layer and surface layer are respectively added to the three barrels of the co-extruder;

[0027] (2) Heating. The materials in the three barrels of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com