Bowl-shaped product manufacturing device

A manufacturing device and bowl-shaped technology, applied in the field of bowl-shaped product manufacturing devices, can solve the problems of slow molding, complicated process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

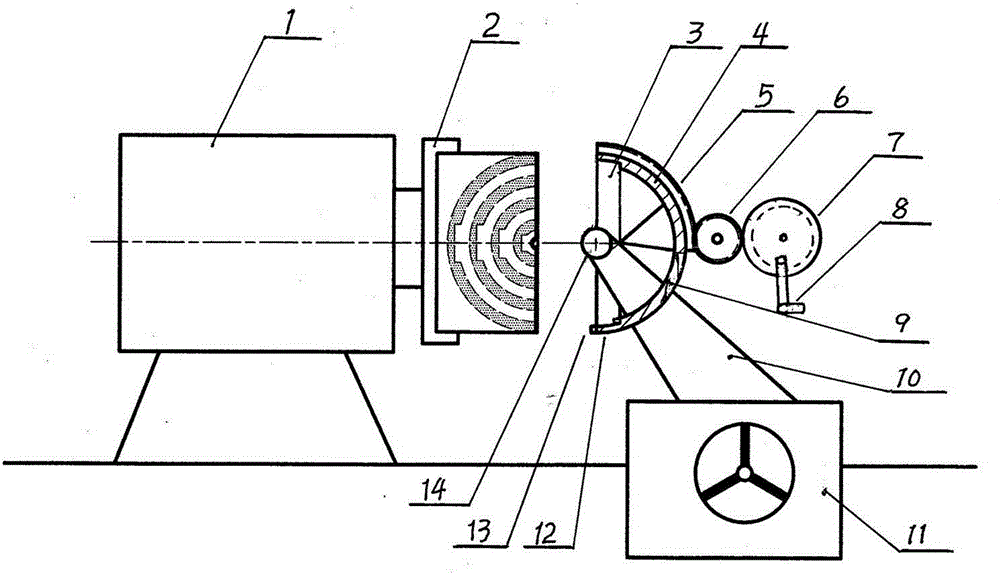

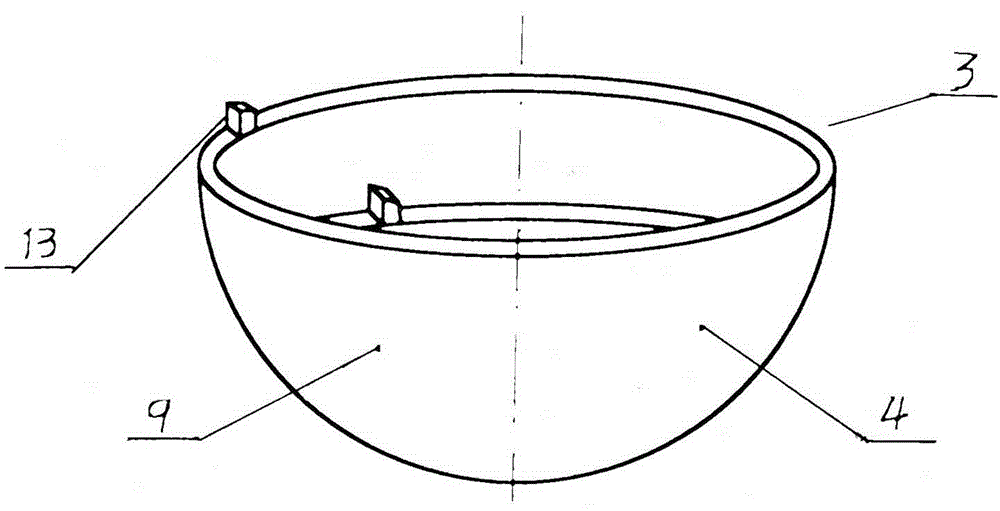

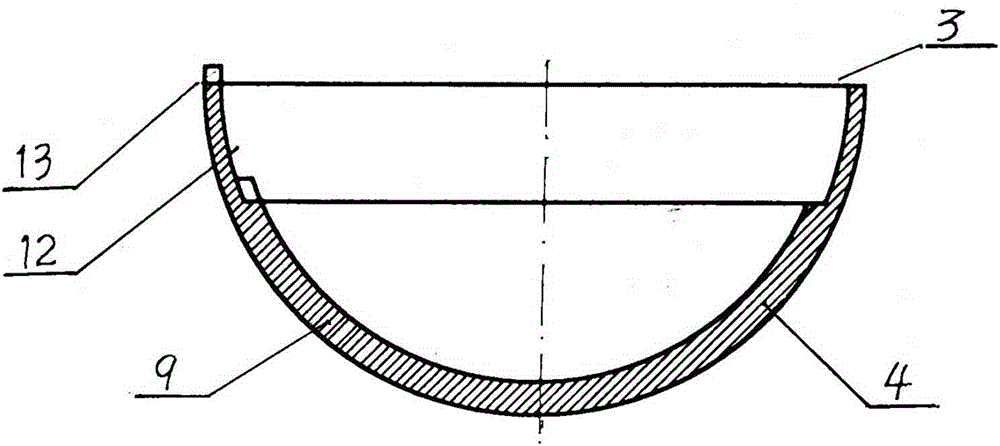

[0010] In conjunction with the accompanying drawings and embodiments, the specific structure of the invention is further described.

[0011] The present invention creates an embodiment of a bowl-shaped product manufacturing device, and its structure includes: a lathe 1, a clamp 2, a cutter 3, a knife rest 10, and a cutter propulsion mechanism 11, wherein the cutter 3 adopts a hemispherical crown cutter, and the handle 4 is 1 / 4 Spherical crown handle, the inner wall of the handle 4 is connected with the handle shaft 14 on the knife holder through a connecting rod, and a 1 / 4 spherical crown blade 9 is connected to one side of the handle 4, and the blade 9 The edge of the mouth is a stepped edge 12, and a front blade and a rear blade 13 are respectively arranged on the stepped edge, and a 1 / 4 ring gear 5 is embedded on the outer wall of the handle 4. The frame is connected with the ring gear through the transmission gear 6 and the driving gear 7, and the driving gear 7 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com