Novel rotary special-shaped polishing machine

A rotary, polishing machine technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. The effect of enhanced flexibility and improved grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

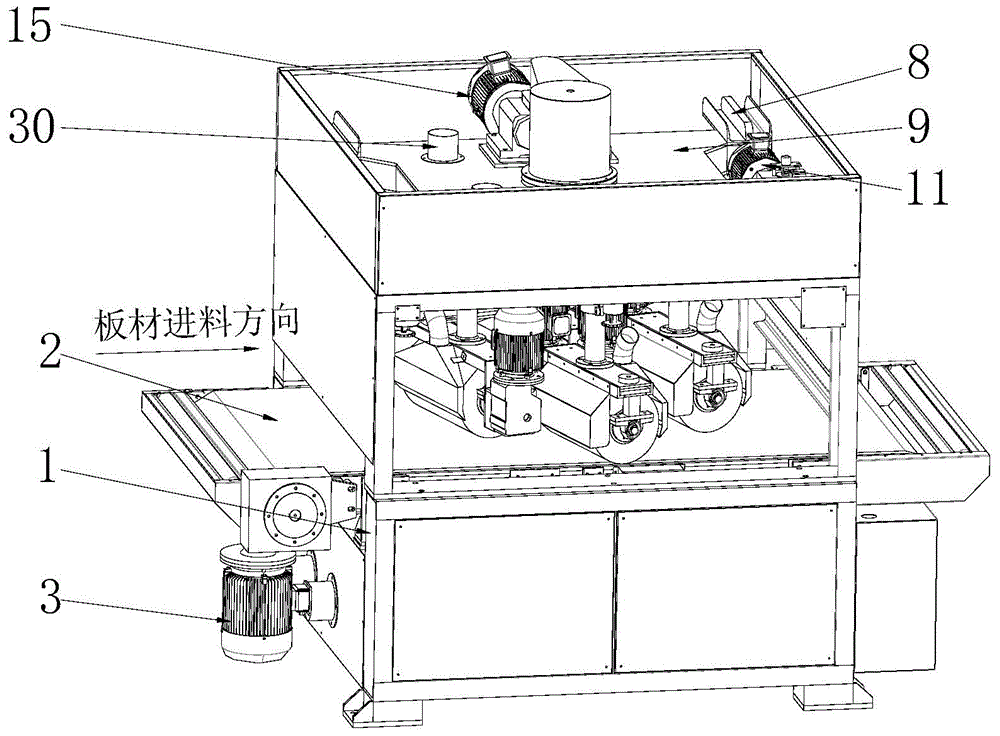

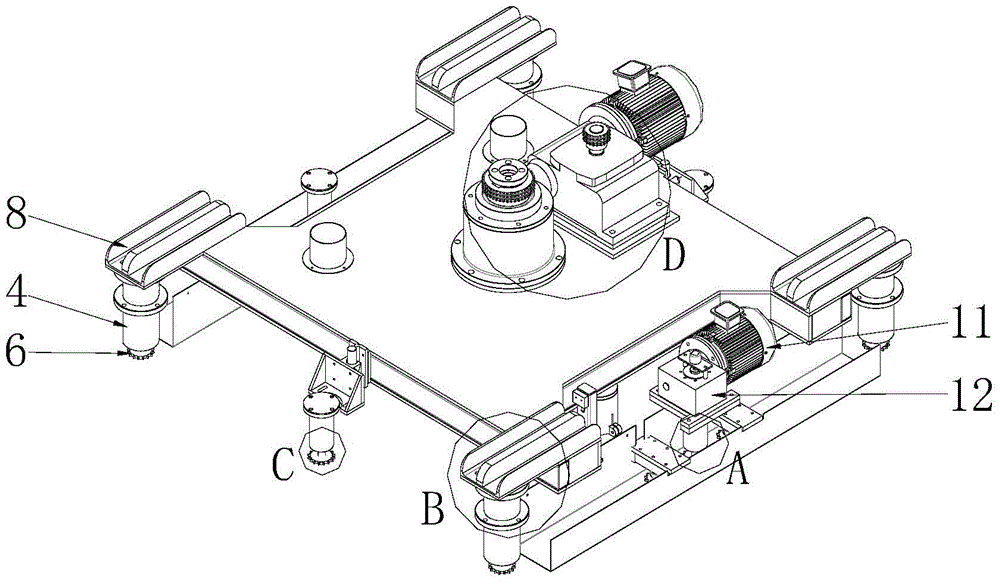

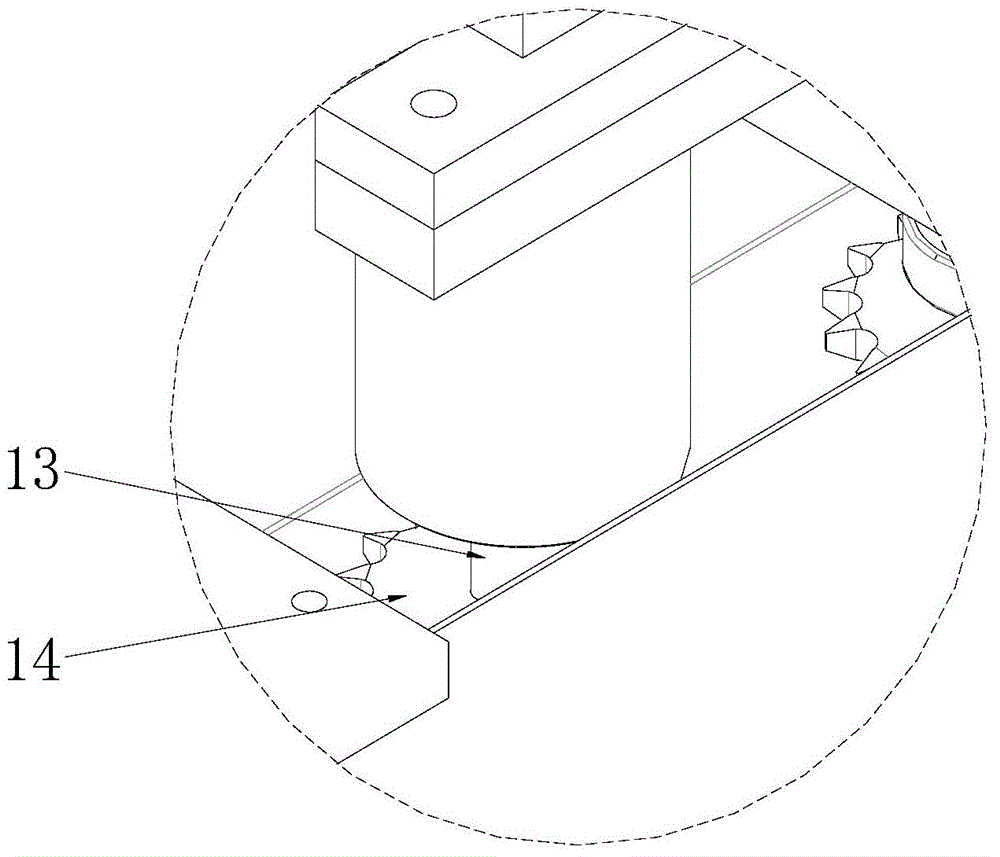

[0042] Such as Figure 1-5 In the polishing machine shown, a conveyor belt 2 as a transmission device is installed on the frame 1, and the conveyor belt 2 is driven by a conveying drive motor 3. Above the conveyor belt 2, 4 lifting guide columns 4 are also installed on the frame 1, and the lifting screw rod 5 that can be vertically lifted relative to the lifting guide column 4 is installed in each lifting guide column 4, and the end of the lifting screw rod 5 is installed with a The first driven sprocket 6 of the driven drive wheel and the top of the lifting screw 5 are equipped with a connecting flange 7, which is connected to the lifting platform 9 through a connecting block 8. In addition, several auxiliary guide columns 10 are installed on the frame 1, and the lifting screw 5 that can be vertically lifted relative to the auxiliary guide column 10 is also installed on the auxiliary guide column 10. The end of the lifting screw 5 is also installed with a first slave. Moving...

Embodiment 2

[0050] The difference between this embodiment 2 and embodiment 1 is that in this embodiment 2, if Figure 11 , 12 As shown, the frame 1 is also provided with a pressure roller 35 that can rotate relative to the frame 1. The pressure roller 35 is located upstream of the conveyor belt 2 to ensure that the position of the plate entering the polishing machine will not deviate. In addition, a linear guide rail 36 is installed on the frame 1 , and the guiding axis of the linear guide rail 36 is perpendicular to the conveying direction of the conveyor belt 2 . The two ends of the pressure roller 35 are connected with the slide block of the linear guide 36 . Utilizing the linear guide rail 36, the pressure roller 35 can be raised and lowered relative to the conveyor belt 2 to adapt to plates of different thicknesses. For the convenience of adjustment, an adjustment screw 43 can be installed on the slider, and a handle 44 can be installed at the end of the adjustment screw 43, so tha...

Embodiment 3

[0052] The difference between this embodiment 3 and embodiment 2 is that in this embodiment 3, if Figure 13-16 As shown, an anti-collision device is also installed on the frame 1, and the anti-collision device includes a baffle left fixture 37 installed on the frame 1, a baffle right fixture 38, and a baffle left fixture 37 and a baffle right fixture. 38 and a baffle 39 that can rotate relative to the frame 1, and the baffle 39 is formed with a blocking surface 40 that is inclined to the conveying direction of the transmission device. Such as Figure 14 , 15 As shown, a torsion spring 41 is also provided between the baffle plate 39 and the baffle plate left piece 37 , one end of the torsion spring 41 is fixed on the baffle plate left piece 37 , and the other end is attached to the baffle plate 39 . The distance between the lowest end of the baffle plate 39 and the conveyor belt 2 is equal to the distance between the polishing roller 29 and the conveyor belt 2 . When the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com