Nasal cavity support frame, nasal cavity support frame bracket and method for manufacturing the nasal cavity support frame by microdrop spraying

A technology of microdroplet spraying and manufacturing method, which is applied to stents and other directions, can solve the problems of expensive nasal cavity stents made of memory alloys, severe patient rejection, and inconvenient access and placement. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

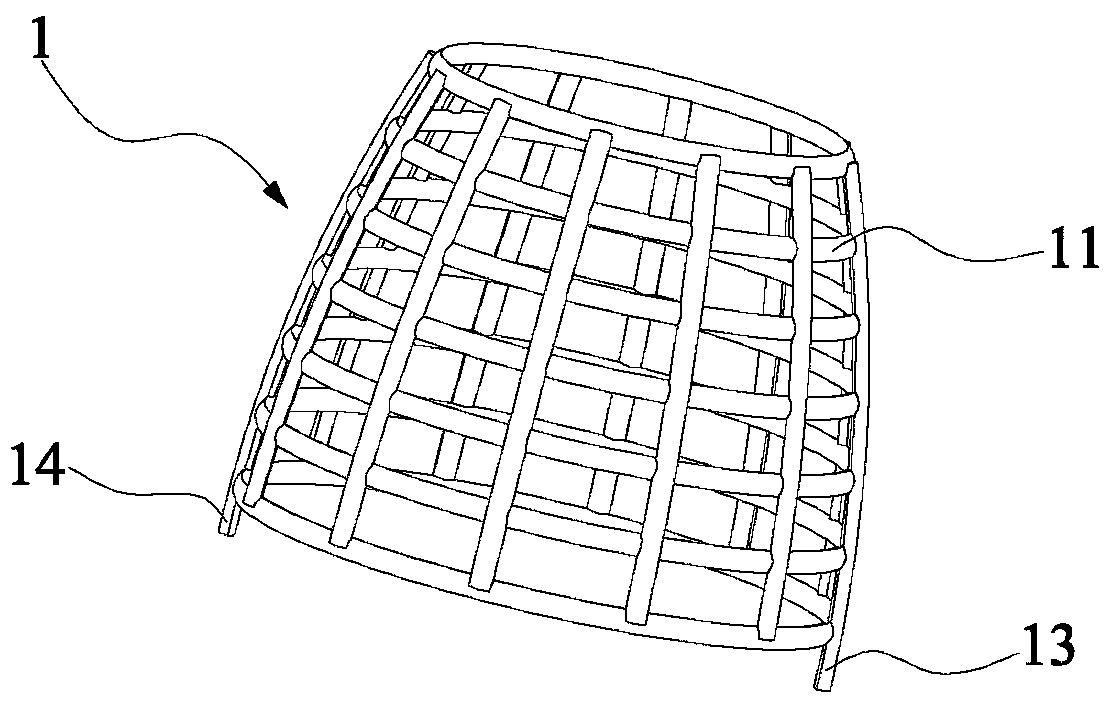

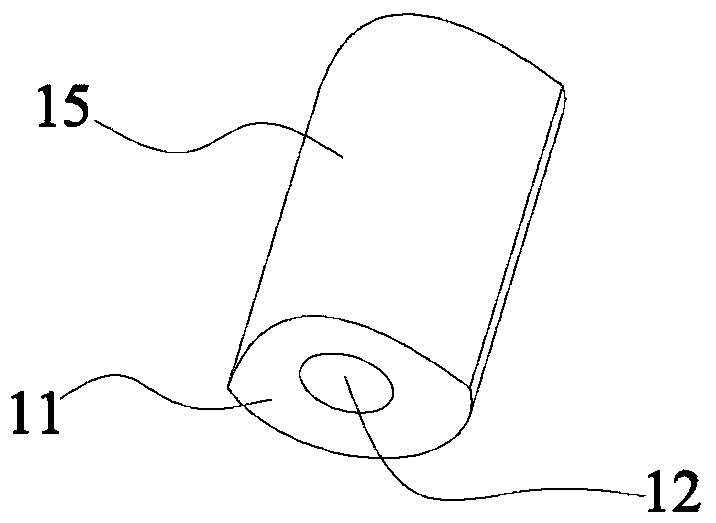

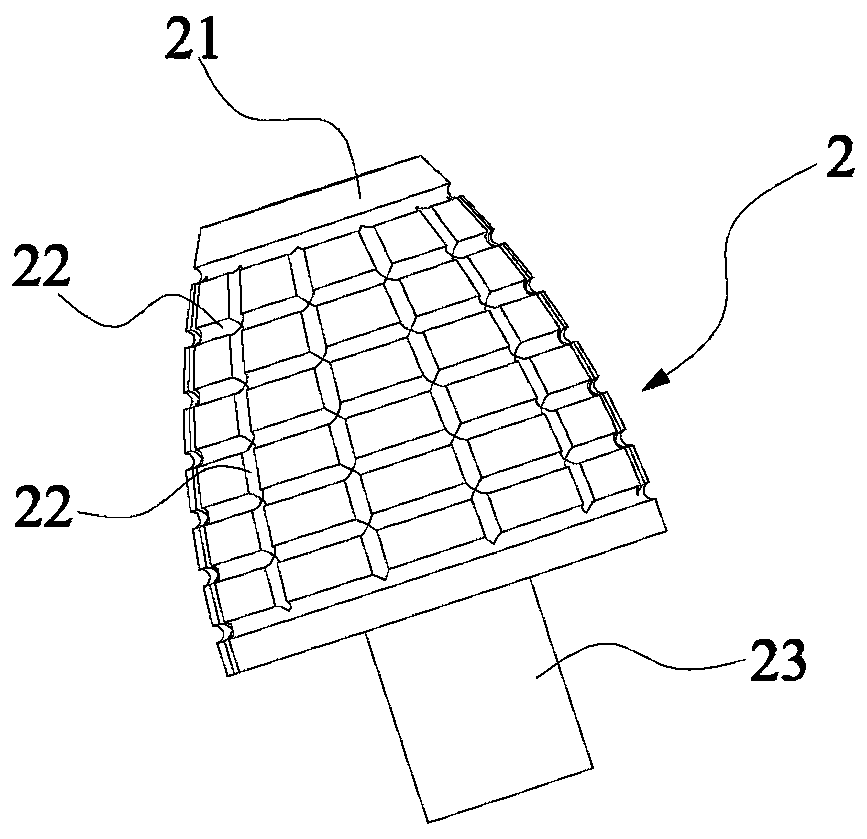

[0040] What the present invention discloses is a kind of nasal cavity supporting frame, such as figure 1 and figure 2 Shown is a preferred embodiment of the present invention. The nasal cavity support frame 1 is made of elastic material, which is a mesh structure 11 similar to the contour of the nasal cavity of a human body. For the convenience of manufacture, a conical mesh structure without top can be used. The interior of the mesh structure 11 is a hollow space connected to each other. The structure thus forms the air flow channel 12 . An air inlet 13 is arranged at the bottom of the mesh structure 11, and an air inlet valve (not shown in the figure) is arranged at the air inlet 13, and the air inlet valve can adopt a valve structure similar to a swimming circle, a basketball, or the like.

[0041] Further, for the convenience ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com