A device for automatically flipping and inserting panels

A technology of automatic flipping and board parts, which is applied in the direction of electrical components, printed components, electrical connection formation, printed circuit manufacturing, etc. problems, to achieve the effect of reducing the contact defect rate of the board, efficient and stable output, and improving the yield of the board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further detailed below in conjunction with the drawings:

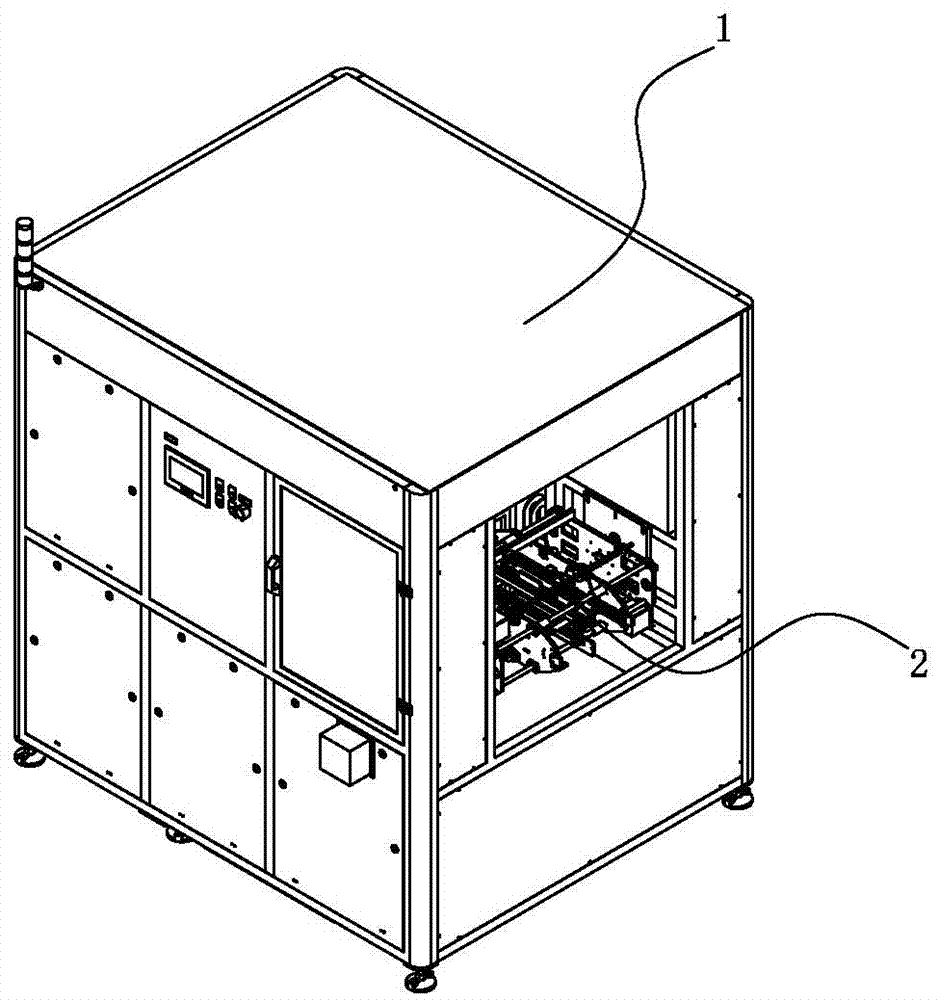

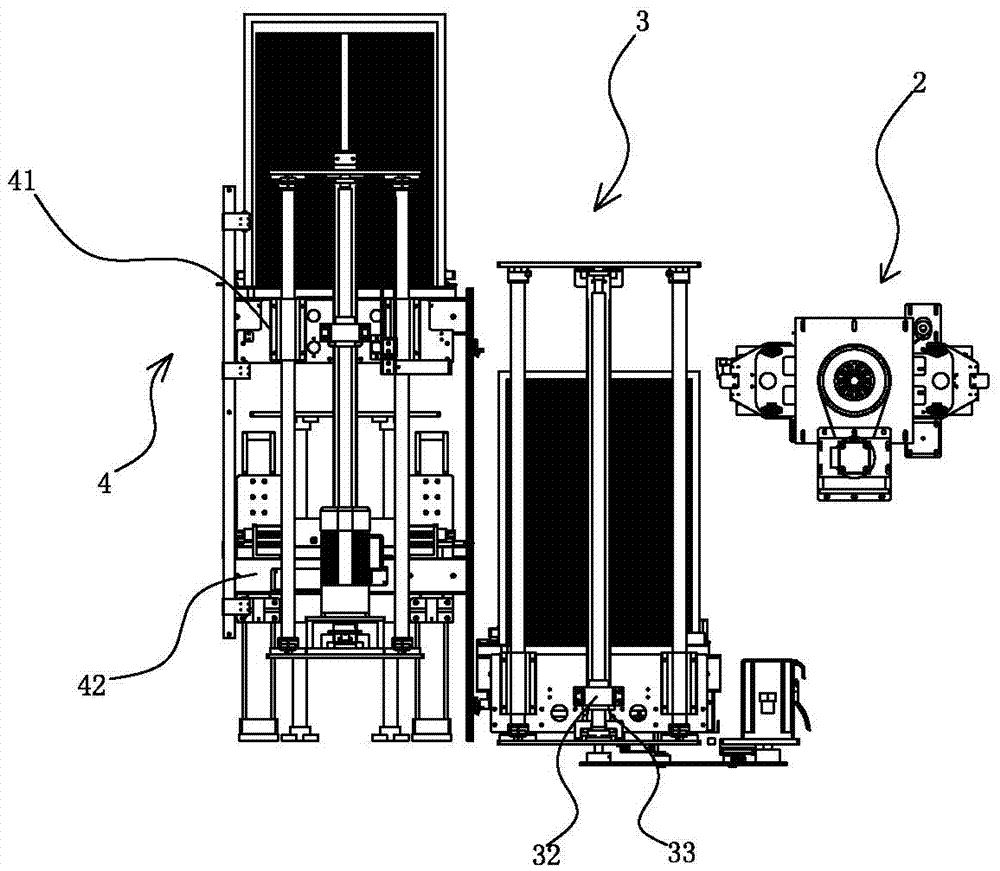

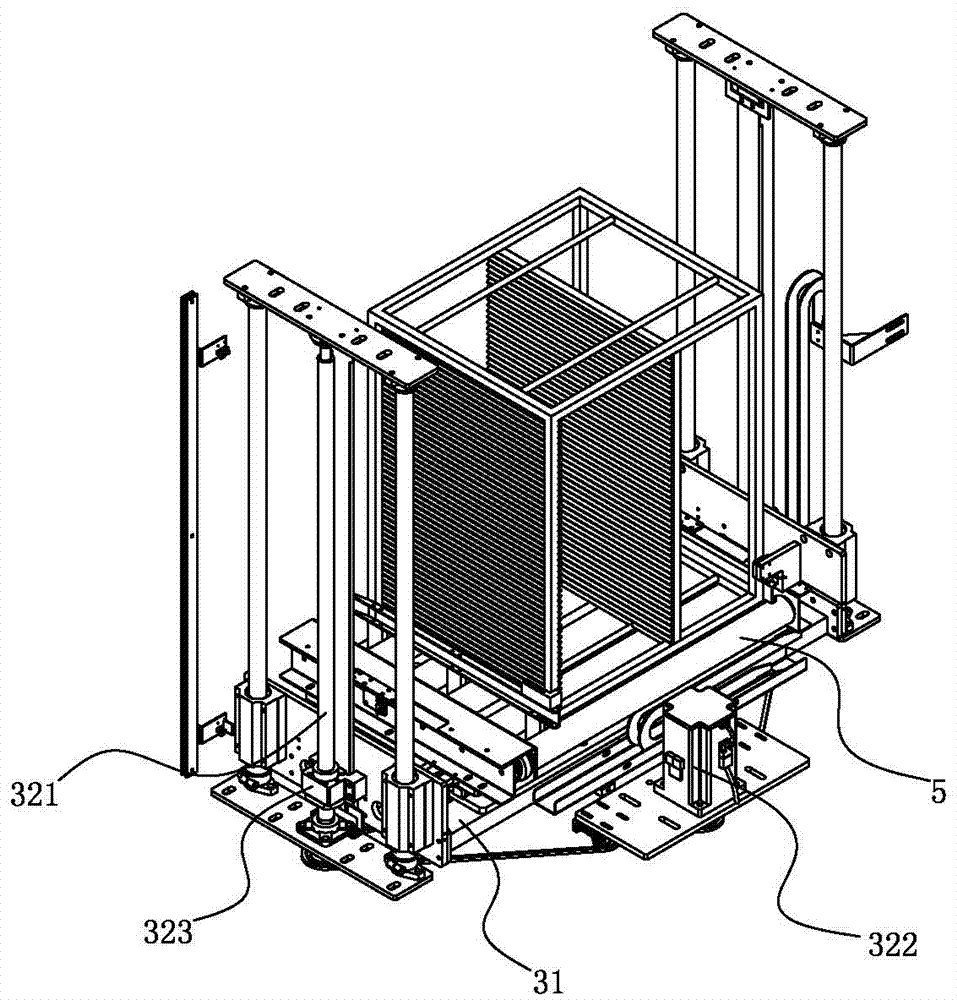

[0031] Such as Figure 1 to Figure 7 As shown, an embodiment of a device for automatically turning over a frame for a panel according to the present invention includes a bracket 1 and a conveying and turning mechanism 2 installed in the bracket 1 and a frame lifting and lowering mechanism that cooperates with the conveying and turning mechanism 2 The mechanism 3 and the frame access mechanism 4 matched with the frame lifting mechanism 3,

[0032] The conveying and turning mechanism 2 clamps the plate that enters the designated position of the conveying and turning mechanism 2. After the conveying and turning mechanism 2 is turned, the plate is inserted into the empty frame on the frame lifting mechanism 3; for a certain batch Before the production of the secondary plate, the operator sets the plate size parameters through the man-machine interface, and the plate is transported into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com