A kind of non-woven ceramic diaphragm for lithium ion battery and preparation method thereof

A lithium-ion battery, ceramic separator technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of poor coating uniformity, poor dispersion, etc. The effect of polarity and hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

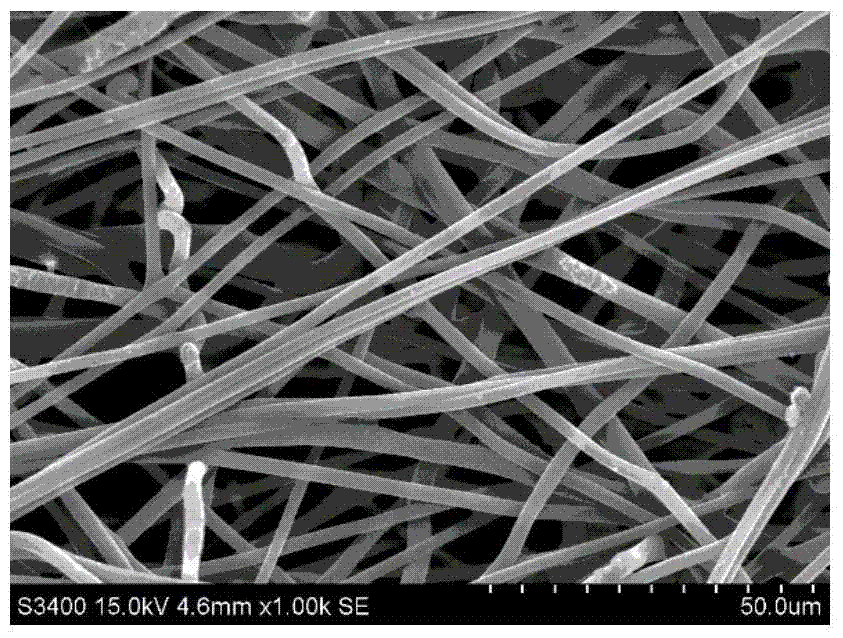

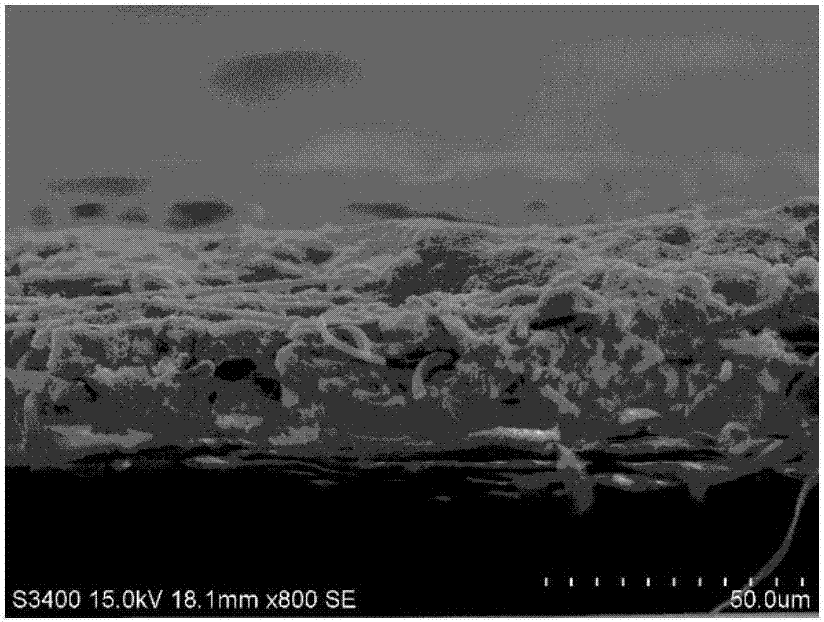

Image

Examples

preparation example Construction

[0034] A preparation method of a non-woven ceramic diaphragm for a lithium-ion battery, comprising the following steps:

[0035] (1) Pretreatment of non-woven fabrics: Utilize catechol derivative solution to modify non-woven fabrics, introduce active groups on the surface of non-woven fabrics and fiber pores, and obtain modified non-woven fabrics;

[0036] (2) Preparation of sol coating solution by alkali / acid sol-gel method: add orthosilicate ethyl ester, water, alcohol and ammonia water in turn to reaction bottle A, stir and react at room temperature for 4-12 hours, and the stirring speed is 1200-1400rpm, Form alkali sol A; add orthosilicate ethyl ester, water, alcohol and acid to reaction bottle B in sequence, stir at room temperature for 30 minutes, stirring speed is 1200-1400rpm, form acid sol B; finally add acid sol B to alkali sol A and place the reaction bottle in an oil bath at 30-90°C for 1-6 hours to prepare a sol coating solution containing nano-silica microspheres...

Embodiment 3

[0049] A preparation method of a non-woven ceramic diaphragm for a lithium-ion battery, comprising the following steps:

[0050] (1) Pretreatment of non-woven fabrics: soak PP non-woven fabrics with a thickness of 35 μm and a porosity of 65% in 1.5 g / L methacryl dopamine solution for 48 hours, and wash off the surface-adhered particles with distilled water. Methacryloyl dopamine was dried naturally to obtain a modified non-woven fabric;

[0051] (2) Preparation of sol coating solution by alkali / acid sol-gel method: add orthosilicate ethyl ester, water, ethanol and ammonia water to reaction bottle A in sequence, stir and react for 4 hours at room temperature, and the stirring speed is 1200rpm to form alkali sol A; in addition, add ethyl orthosilicate, water, ethanol and hydrochloric acid successively in reaction flask B, stir at room temperature for 30min, stirring speed is 1200rpm, form acid sol B; finally join acid sol B in alkali sol A and The reaction bottle was placed in ...

Embodiment 4

[0056] A preparation method of a non-woven ceramic diaphragm for a lithium-ion battery, comprising the following steps:

[0057] (1) Pretreatment of non-woven fabrics: soak PE non-woven fabrics with a thickness of 38 μm and a porosity of 62% in a 3g / L dopa solution for 48 hours, wash off the dopa attached to the surface with distilled water, and naturally Dry to obtain the modified non-woven fabric;

[0058] (2) Preparation of sol coating solution by alkali / acid sol-gel method: add orthosilicate ethyl ester, water, isopropanol and ammonia water in turn in reaction bottle A, stir and react at room temperature for 12 hours, and the stirring speed is 1300rpm to form alkali Sol A; In addition, add ethyl orthosilicate, water, isopropanol and nitric acid to the reaction bottle B in sequence, stir at room temperature for 30 minutes, and the stirring speed is 1300rpm to form acid sol B; finally add acid sol B to alkali sol A The reaction bottle was placed in an oil bath at 90° C. for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com