75 MVA transformer capable of realizing pressure relief and explosion prevention

A technology for transformers and pressure sensors, applied in transformer/inductor casings, transformer/inductor cooling, instruments, etc., can solve problems such as fuel injection or fuel tank bursts, prevent secondary accidents, simplify design, and improve explosion-proof performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

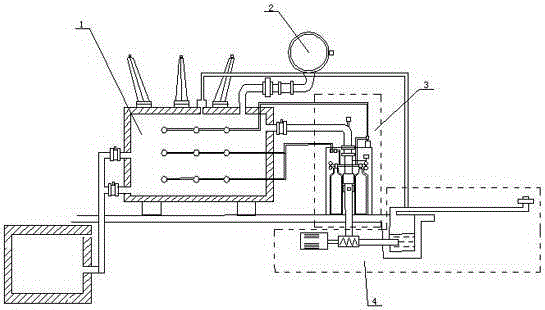

[0049] A pressure relief and explosion-proof 75MVA transformer of the present invention includes a fire extinguishing mechanism 3 connected to the transformer 1, a pressure release mechanism 4, a leak detection mechanism and a control mechanism;

[0050] Transformer 1, including shell, oil conservator 2, iron core, winding; oil conservator 2 is arranged on the upper end of the shell, and is connected with the shell through a pipeline, and the pipeline is provided with a gas relay and a shut-off valve; three-phase winding It is installed in the housing, and the winding is wrapped with an iron core. A temperature sensor is installed at the upper, middle and lower positions of the three-phase winding; a pressure sensor is respectively installed at the upper, middle and lower parts of the housing;

[0051] The fire extinguishing mechanism 3 includes a fire extinguishing box, a fire extinguishing tank, and a gas booster pump; the fire extinguishing tank is arranged in the fire extin...

specific Embodiment 2

[0064] Transformer 1 unit, including shell, oil conservator 2, iron core, winding; oil conservator 2 is fixed on the top of the shell and connected to the shell through the gas relay and shut-off valve; the three-phase winding is set in the shell, each winding Wrapped with an iron core, a temperature sensor is installed at the upper, middle and lower positions of each winding; a pressure sensor is respectively installed at the upper, middle and lower parts of the casing to detect the oil temperature or gas temperature in the casing; the transformer There is a basement under 1;

[0065] The pressure release unit includes an oil discharge tank, an oil discharge pool, an oil discharge pump, an igniter, and a pressure release valve; the oil discharge tank is located in the basement below the transformer 1, and there is a solenoid valve on the middle and lower outside of the transformer 1 housing, The two solenoid valves are connected in parallel to the oil discharge tank; there is...

specific Embodiment 3

[0075] (3) When the pressure inside the transformer 1 is greater than 61kpa, the controller controls the solenoid valve connected to the oil discharge tank in the middle of the transformer 1 to open to transfer the transformer 1 oil to the oil discharge tank;

[0076] (4) When the pressure inside the transformer 1 is greater than 70kpa, the controller controls the solenoid valve connected to the oil discharge tank at the lower part of the transformer 1 to open;

[0077] (5) When the pressure in the oil discharge tank is greater than 55kpa, the safety valve at the lower end of the oil discharge tank is opened;

[0078] (6) When the pressure inside the transformer 1 drops to 55kpa, the control unit controls the solenoid valve of the pipeline connected to the oil discharge tank on the transformer 1 to close;

[0079] (7) The airflow is detected at the exhaust port, and the control unit controls the igniter to ignite.

[0080] Due to the above method, the pressure can be effectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com