Authentication method for composite fiber

A composite fiber and fiber technology, which is applied in the field of composite fiber identification, can solve the problems of composite fiber identification uncertainty, prone to errors and omissions, and high bending stability of side-by-side composite fibers, so as to reduce inspection costs and inspection cycles, and reduce manpower Effects of cost-effective fiber inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

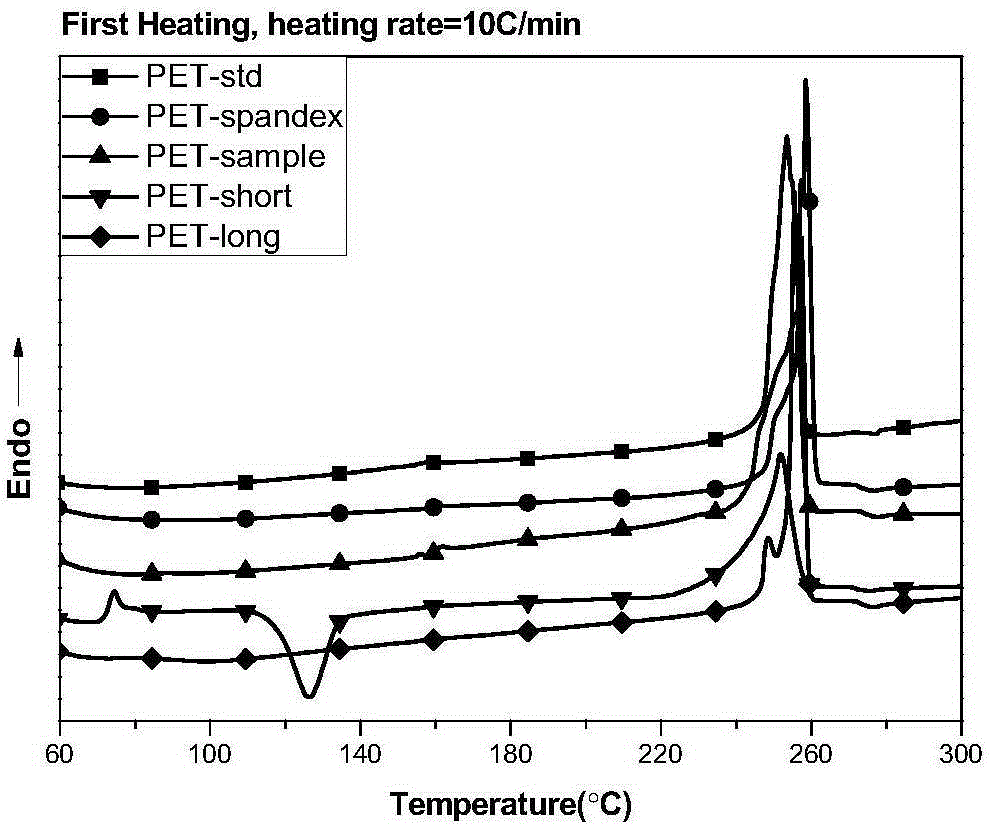

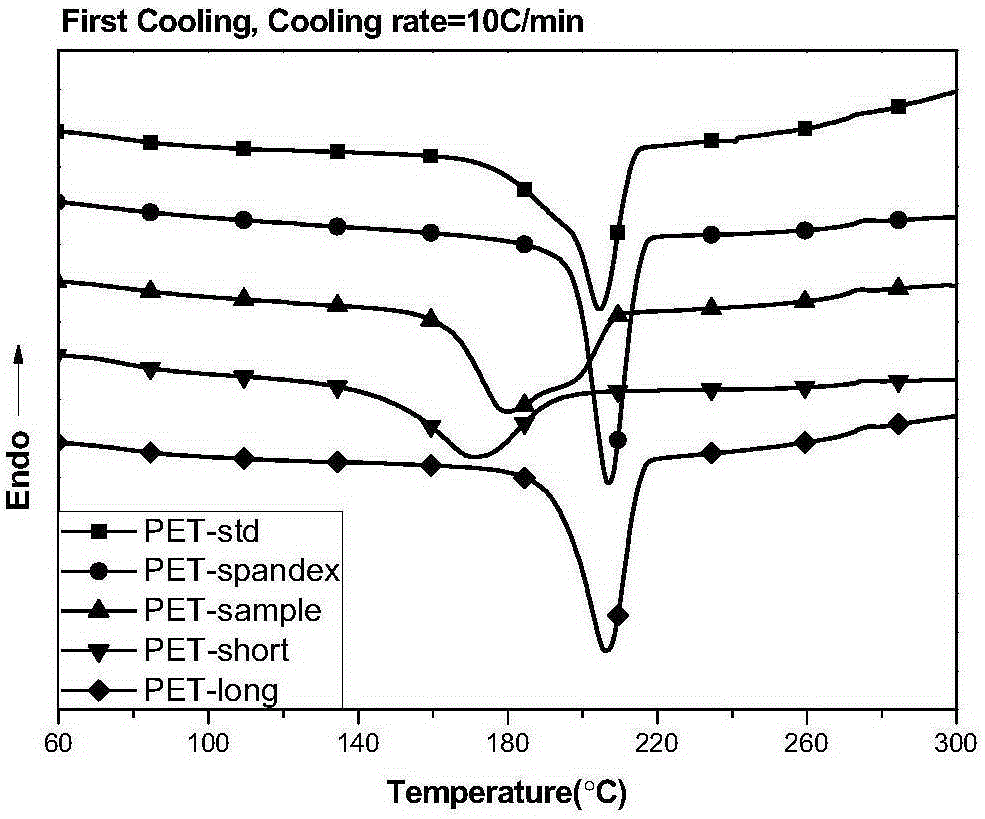

[0055] Embodiment 1 Differential scanning calorimetry analysis condition screening

[0056] 1. Determination of the maximum temperature.

[0057] In order to achieve the purpose of obtaining real thermal analysis data of fiber samples and protecting the instrument, it is necessary to reasonably set the maximum temperature of the differential scanning calorimetry test to ensure that the sample does not decompose under the condition of melting the sample.

[0058] However, all materials suffer from thermal hysteresis when subjected to thermal analysis testing, especially materials with poor thermal conductivity such as textiles. The fundamental reason for the thermal hysteresis effect is that there is a temperature gradient between the surface layer and the inner layer of the fiber sample during the heat absorption or heat release process. During the heating process, the greater the heating rate, the more serious the thermal hysteresis, which will easily lead to a larger measur...

Embodiment 2

[0081] A method for identifying composite fibers, the operation process is as follows Figure 13 shown, including the following steps.

[0082] 1. Establish a database of standard fiber samples.

[0083] Get different types of single-component standard fiber samples, in the present embodiment, the fiber standard samples include: polyethylene (polyethylene) fiber (PE), polypropylene (polypropylene) fiber (PP), polyester fiber (PET) , Polyamide fiber (PA). Those skilled in the art know that the fiber types in the fiber standard sample database can be selected, added and adjusted according to actual detection needs.

[0084] Use a ball mill or grinder to fully short the fiber standard sample to a length of 1-3 mm, and mix it evenly, and then perform thermogravimetric analysis on the above fiber standard sample. In this embodiment, the selected thermogravimetric analysis test conditions are: Nitrogen atmosphere, the initial heating temperature is 50°C, the maximum heating tempe...

Embodiment 3

[0111] In this embodiment, the composite fiber sample 3 is tested according to the above-mentioned differential scanning calorimetry conditions and steps, and the primary cooling and secondary heating DSC spectra of the composite fiber sample 3 are obtained. The results are as follows Figure 20-21 Shown, and each characteristic temperature obtained by analysis is shown in Table 4.

[0112] Table 4 Differential scanning calorimetry analysis data of composite fiber sample 3

[0113]

[0114] Compare the differential scanning calorimetry data of the composite fiber sample 3 obtained above with the characteristic temperature of the primary cooling and the characteristic temperature of the secondary heating in the pre-established fiber standard sample differential scanning calorimetric analysis database, and the identification results are shown in the table 5.

[0115] Table 5 Analysis and Judgment Results of Composite Fiber Sample 3

[0116]

[0117]

[0118] From the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com