Constant temperature electrical heating urea liquid inlet pipe

A urea tube, electric heating technology, applied in the direction of the muffler, engine components, machines/engines, etc., can solve the problems of fire, overheating, etc., achieve good point insulation and flame retardancy, easy installation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

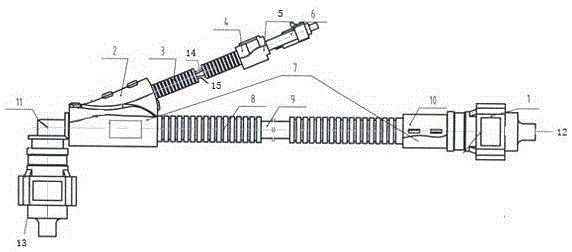

[0010] Such as figure 1 A constant temperature electric heating urea liquid inlet pipe shown includes a urea pipe body 9, first heat-shrinkable tubes 7 are installed on both sides of the urea tube body 9, and a wiring harness is installed on the first heat-shrinkable tube 7 at one end An end ferrule 2, a straight end ferrule 10 is installed on the first heat-shrinkable tube 7 at the other end; a first urea tube quick connector 1 and a second urea tube quick connector 11 are respectively installed at both ends of the urea tube body 9 , the first urea pipe quick connector and the second urea pipe quick connector can be selected according to actual conditions. The second urea tube quick connector 11 is equipped with a dust cover 13; the urea tube body 9 is covered with a first nylon bellows sheath 8; the wire harness end ferrule 2 and the second nylon bellows sheath 3 connection, the second nylon bellows sheath 3 is connected with the plug-in ferrule 4, and the second heat shrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com