Assembly type composite floor slab

A technology of superimposed floor slabs and assembly, which is applied to floors, building components, buildings, etc., can solve the problems of small load range, increased structural self-weight, and poor shear resistance, so as to increase bearing capacity, speed up construction, reduce The effect of small self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

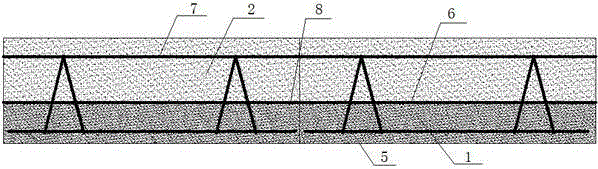

[0031] Reference attached figure 2 , the truss 5 is an inverted V-shaped structure, and the material is steel bars, and each truss 5 is connected as a whole by negative bending moment steel bars 7 .

Embodiment 2

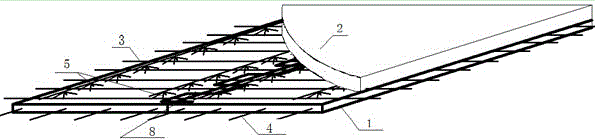

[0033] Reference attached image 3 and Figure 4 , the truss 5 includes three web rods, and the tops of the three web rods intersect at a point, and each truss 5 is connected as a whole by the negative bending moment steel bar 7 .

Embodiment 3

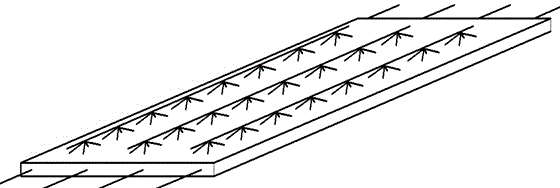

[0035] Reference attached Figure 5 , the truss 5 is an inverted triangular structure, the material is steel bars, and each truss 5 is connected as a whole by the negative bending moment steel bar 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com