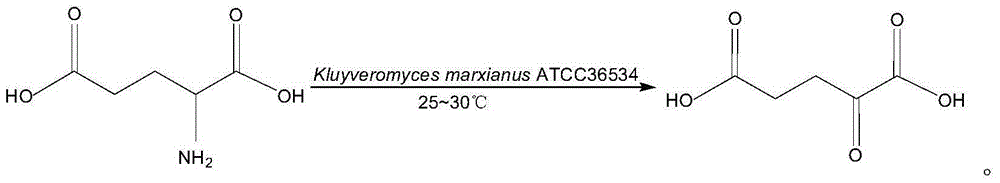

Method for synthesizing alpha-ketoglutaric acid by biological conversion method

A technology of ketoglutaric acid and biotransformation, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Screening of transformed yeast strains

[0027] Seven yeast strains were purchased from the market, including 2 strains of Saccharomyces cerevisiae, 1 strain of Pichia pastoris, 1 strain of Candida guilliermond, 1 strain of Sporidiobolus johnsonii, One strain of Kluyveromyces marxianus and one strain of Candida tropicalis. Among them, Kluyveromyces marxianus (Kluyveromyces marxianus) was purchased from the American Type Culture Collection, with the preservation number ATCC36534.

[0028] Firstly, pick a ring full of bacteria from the above-mentioned yeast slant strains stored in the refrigerator, inoculate it in a fresh slant medium, and culture the slant in a biochemical incubator at 30°C for 36 hours to obtain an activated yeast strain slant. Pick 4 full rings of bacteria from the activated strain slant, inoculate into a 250mL Erlenmeyer flask containing 50mL of transformation medium, and shake the flask at 30°C and 200r / min for 24h after transformation (c...

Embodiment 2

[0034] Example 2: H 2 o 2 Choice of Concentration

[0035] After confirming that Kluyveromyces marxense ATCC36534 was used as the strain for transforming L-glutamic acid into α-ketoglutarate, H 2 o 2 As an inhibitor of α-ketoglutarate dehydrogenase, H 2 o 2 the optimal concentration of addition.

[0036] First, pick 1 full ring of bacterial cells from the Kluyveromyces marxense ATCC36534 slant strain stored in the refrigerator, inoculate it on a fresh slant medium, and culture the slant surface in a biochemical incubator at 30°C for 24 hours to obtain an activated Kluyveromyces marxii strain ATCC36534 inclined plane. Pick 2 rings of bacteria from the activated strain slant and put them into 50mL seed medium (in a 250mL Erlenmeyer flask). Seed culture is based on a constant temperature shaking shaker at 30°C, 200r / min shaking culture for 24h, and dry The seed solution with a bacterium concentration of 5.35g / L. Use a sterile pipette to draw 5 mL of seed solution of ATCC3...

Embodiment 3

[0040] Embodiment 3: the selection of methotrexate concentration

[0041] After confirming that Kluyveromyces marxense ATCC36534 was used as the strain for converting glutamic acid into α-ketoglutarate, methotrexate was added to the medium as an inhibitor of α-ketoglutarate dehydrogenase. This implementation class The optimal concentration of methotrexate was selected for optimization.

[0042] First, pick 1 full ring of bacterial cells from the Kluyveromyces marxense ATCC36534 slant strain stored in the refrigerator, inoculate it on a fresh slant medium, and culture the slant surface in a biochemical incubator at 30°C for 24 hours to obtain an activated Kluyveromyces marxii strain ATCC36534 inclined plane. Pick 2 rings of bacteria from the activated strain slant and put them in a Erlenmeyer flask containing 50mL of seed medium (in a 250mL Erlenmeyer flask). Seed culture is based on a 30°C constant temperature shaking shaker, 200r / min shaking culture for 24h , to obtain a dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com