Frame sealing adhesive composition and preparation method thereof

A technology for sealing frame glue and filler, applied in the field of frame sealing glue composition and preparation thereof, can solve problems such as breakage, decreased productivity, burr at break, etc., and achieves the effect of avoiding burr or breakage and having good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] As a preferred embodiment of the present invention, the frame sealant includes the following raw materials in parts by weight: 7-10 parts of epoxy resin, 0.5-1 part of dispersant, nano-SiO 2 0.5-1.5 parts of microparticles, 60-70 parts of acrylic resin, 0.5-0.8 parts of coupling agent, 6-9 parts of thermal curing agent, 0.3-0.5 parts of photoinitiator, 0.1-0.3 parts of molecular weight regulator, 4-0 parts of organic filler 6 parts, 6 to 8 parts of inorganic fillers.

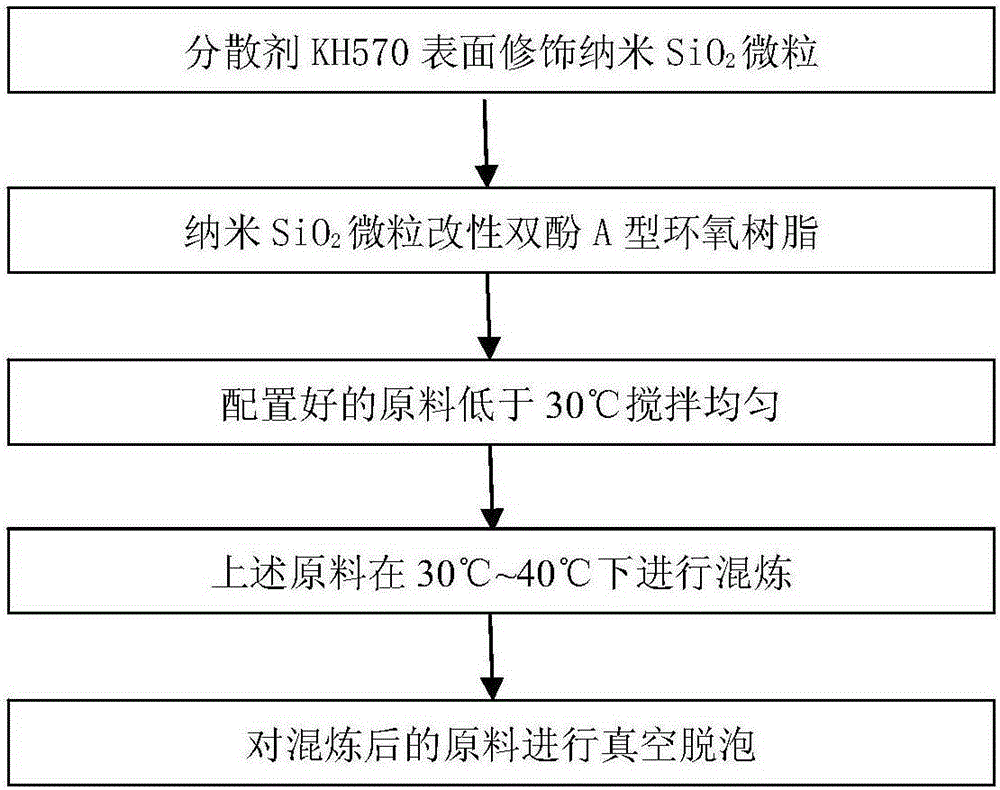

[0046] The preparation method of the frame sealing glue provided by the invention comprises the following steps:

[0047] (1) Add the dispersant to the solvent and stir evenly, then add nano-SiO 2 Microparticles, continue to stir to fully disperse the components to obtain dispersion system 1; then add epoxy resin to dispersion system 1, fully stir, high-speed shear emulsification to further disperse, and obtain dispersion system 2;

[0048] (2) Stir the obtained dispersion system 2 and other components ...

Embodiment 1

[0055] This embodiment provides a frame sealant, which is composed of the following raw materials in parts by weight: 8 parts of bisphenol A epoxy resin, 0.5 parts of dispersant KH570, and nano-SiO with a particle size of 60 mm 2 0.5 parts of microparticles, 63 parts of methyl methacrylate, 0.7 parts of coupling agent KH5700, 10 parts of thermal curing agent isophorone diamine, 0.7 parts of photoinitiator 2,2-diethoxyacetophenone, molecular weight 0.6 parts of regulator tertiary dodecyl mercaptan, 4 parts of elastic rubber balls with a diameter of 0.1 μm to 1.0 μm, and 10 parts of silica balls with a diameter of 1.0 μm to 3.0 μm.

Embodiment 2

[0057] This embodiment provides a frame sealant, which is composed of the following raw materials in parts by weight: 9 parts of novolac epoxy resin, 0.5 parts of dispersant KH5700, and nano-SiO with a particle size of 70 mm 2 0.7 parts of microparticles, 65 parts of ethyl tert-butyl acrylate, 0.9 parts of vinyl-trimethoxysilane coupling agent, 8 parts of thermal curing agent ethylenediamine, 0.6 parts of photoinitiator dibenzoyl peroxide, molecular weight modifier 0.3 parts of tertiary dodecyl mercaptan, 5 parts of fully vulcanized styrene-butadiene rubber powder, and 8 parts of silicon carbide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com