Diatom ooze coating and preparation method thereof

A technology of diatom mud coating and diatomite, which is applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of increasing product manufacturing links, reduce pre-dissolution links, and inhibit Microbial growth, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

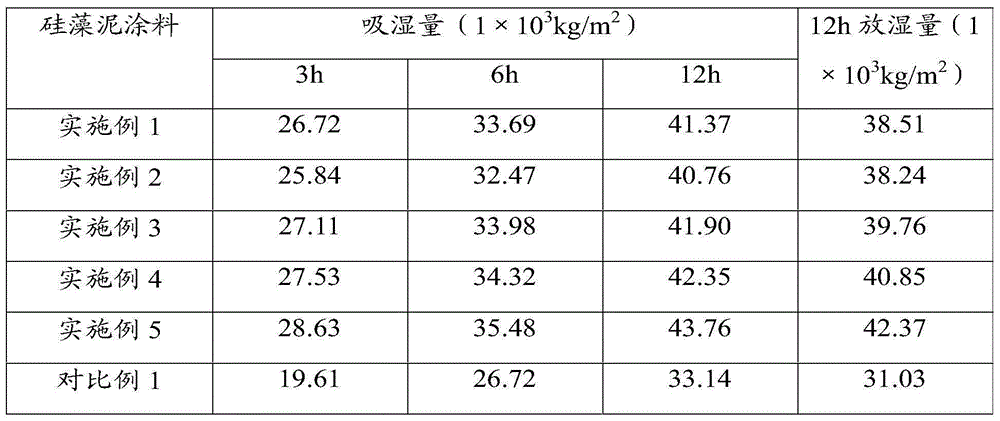

Examples

Embodiment 1

[0032] A kind of diatom mud coating, described diatom mud coating mainly comprises the composition of following mass fraction:

[0033] 5% of synthetic emulsion, 0.1% of dispersant, 10% of diatomaceous earth, 0.01% of silver ion antibacterial agent, and the balance is water.

[0034] The preparation method of described diatom mud coating is as follows:

[0035] First add deionized water in proportion to the stirring tank, add dispersant and diatomaceous earth while stirring, after stirring and dispersing evenly, add synthetic emulsion and silver ion antibacterial agent while stirring, stir until uniformly dispersed, and obtain the silicon Algal mud coating.

[0036] Described synthetic emulsion is styrene-acrylic emulsion;

[0037] The dispersant is potassium polyacrylate;

[0038] The diatomite is 280-580 mesh diatomite.

Embodiment 2

[0040] A kind of diatom mud coating, described diatom mud coating mainly comprises the composition of following mass fraction:

[0041] 25% of synthetic emulsion, 3% of dispersant, 35% of diatomaceous earth, 10% of filler, 1% of silver ion antibacterial agent, 3% of auxiliary agent, and the balance is water.

[0042] The preparation method of described diatom mud coating is as follows:

[0043] Add deionized water in proportion to the mixing tank first, then add dispersant, pigment, diatomaceous earth and filler while stirring, after stirring and dispersing evenly, add thickener while stirring, after stirring and dispersing evenly, add synthetic Stir the emulsion and the silver ion antibacterial agent until they are uniformly dispersed to obtain the diatom mud coating.

[0044] Described synthetic emulsion is silicone acrylic emulsion;

[0045] The dispersant is sodium polycarboxylate;

[0046] The diatomite is 300-400 mesh diatomite.

[0047] Described filler is ground ca...

Embodiment 3

[0050] A kind of diatom mud coating, described diatom mud coating mainly comprises the composition of following mass fraction:

[0051] 5% of synthetic emulsion, 0.3% of dispersant, 20% of diatomaceous earth, 30% of filler, 0.01% of silver ion antibacterial agent, 0.5% of auxiliary agent, and the balance is water.

[0052] The preparation method of described diatom mud coating is as follows:

[0053] Add deionized water in proportion to the mixing tank first, then add dispersant, pigment, diatomaceous earth and filler while stirring, after stirring and dispersing evenly, add thickener while stirring, after stirring and dispersing evenly, add synthetic Stir the emulsion and the silver ion antibacterial agent until they are uniformly dispersed to obtain the diatom mud coating.

[0054] Described synthetic emulsion is vinegar acrylic emulsion;

[0055] Described dispersant is sodium polyphosphate;

[0056] The diatomite is 400-450 mesh diatomite.

[0057] Described filler is li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com