Combined hydrotreatment method and hydrotreatment system for petroleum resin

A petroleum resin and hydrogenation treatment technology, which is applied in the field of resin hydrogenation, can solve problems affecting product quality and distribution, shortening the operation cycle of the device, and affecting catalyst activity, etc., to achieve complete hydrogenation activity, avoid continuous deposition of impurities, and hydrogenation The effect of complete response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

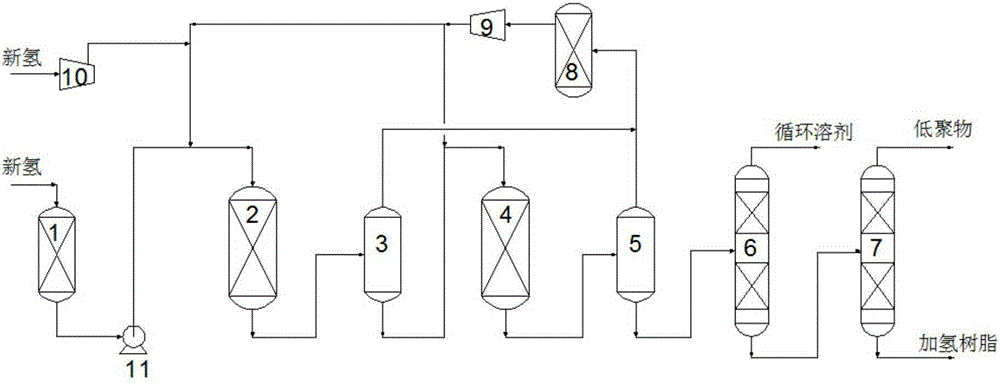

Image

Examples

Embodiment 1

[0053] Follow the steps below for combined petroleum resin hydrotreating:

[0054] (1) Mix the petroleum resin raw material with the circulating solvent at a mass ratio of 1:4, and the circulating solvent is formed by mixing cyclohexane and cycloolefin polymers with a molecular weight of 200 to 500; after high temperature treatment at 230°C, Airspeed 0.2s -1 After being made of alumina and activated carbon according to the spherical shape The adsorbent formed by graded loading is adsorbed to obtain refined petroleum resin;

[0055] In the resulting refined petroleum resin, the salt content is less than 1mg / L, the chlorine content is less than 1ppm, the sulfur content is less than 5ppm, and the gel content is less than 0.1%;

[0056] (2) The refined petroleum resin is mixed with a space velocity of 0.3s -1 Pass through a section of hydrogenation fixed bed filled with hydrogenation catalyst and inert catalyst, the hydrogenation catalyst is a clover-shaped hydrogenation catal...

Embodiment 2

[0060] Follow the steps below for combined petroleum resin hydrotreating:

[0061] (1) The petroleum resin raw material is mixed with a circulating solvent at a mass ratio of 1:3, and the circulating solvent is formed by mixing cyclohexane with a cycloolefin polymer with a molecular weight of 200 to 500; after high temperature treatment at 220°C, Airspeed 0.1s -1 After being made of alumina and activated carbon according to the spherical shape The adsorbent formed by graded loading is adsorbed to obtain refined petroleum resin;

[0062] In the resulting refined petroleum resin, the inorganic salt content is less than 1mg / L, the chlorine content is less than 1ppm, the sulfur content is less than 5ppm, and the gel content is less than 0.1%;

[0063] (2) The refined petroleum resin is mixed with a space velocity of 0.2s -1 Pass through a section of hydrogenation fixed bed filled with hydrogenation catalyst and inert catalyst, the hydrogenation catalyst is a clover-shaped hydr...

Embodiment 3

[0067] Follow the steps below for combined petroleum resin hydrotreating:

[0068] (1) Mix the petroleum resin raw material with the circulating solvent at a mass ratio of 1:5. The circulating solvent is mixed with toluene and a cycloolefin polymer with a molecular weight of 200-500; 0.3s -1 After being made of alumina and activated carbon according to the spherical shape The adsorbent formed by graded loading is adsorbed to obtain refined petroleum resin;

[0069] In the resulting refined petroleum resin, the inorganic salt content is less than 1mg / L, the chlorine content is less than 1ppm, the sulfur content is less than 5ppm, and the gel content is less than 0.1%;

[0070] (2) The refined petroleum resin is mixed with a space velocity of 0.4s -1 Pass through a section of hydrogenation fixed bed filled with hydrogenation catalyst and inert catalyst, the hydrogenation catalyst is a clover-shaped hydrogenation catalyst with refractory alumina and silicon oxide as the carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com