Pyrotechnic composition for calligraphy and painting creation, and preparation method thereof

A technology of pyrotechnics, calligraphy and painting, applied in the direction of ammonium perchlorate composition, etc., can solve the problems of manpower, material and financial resources, artificial cooling, toxic gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

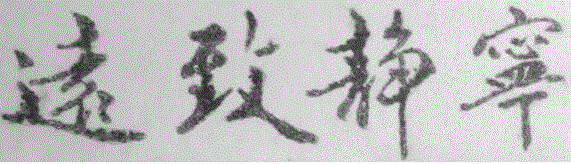

Image

Examples

Embodiment 1

[0027] (1) Quantitatively weigh 42 parts of ammonium perchlorate, 28 parts of metaldehyde, 25 parts of copper chloride and 5 parts of shellac according to the formula ratio;

[0028] (2) Fully grind the weighed ammonium perchlorate, metaldehyde, and copper chloride in a mortar, respectively, and sieve them through 100-200 mesh sieves for 3 times respectively. Reagents are fully dry-mixed;

[0029] (3) Put the weighed shellac into a beaker, add an appropriate amount of 95% ethanol to dissolve it, and after the shellac is completely dissolved, pour the dry-mixed uniform agent described in step (2) into the beaker, and stir thoroughly. Dry the medicine in a cool place until there is no liquid;

[0030] (4) Scrape the dried agent described in step (3) out of the beaker, pour it on an 18-mesh granulation sieve for granulation, and then put it in an oven at 60-70°C for drying;

[0031] (5) Pour the dried medicament described in step (4) into a sieve with a mesh size of 100-200 and...

Embodiment 2

[0034] (1) Weigh 40 parts of quantitative ammonium perchlorate, 15 parts of metaldehyde, 35 parts of copper chloride and 10 parts of shellac according to the formula ratio;

[0035] (2) Fully grind the weighed ammonium perchlorate, metaldehyde, and copper chloride in a mortar, respectively, and sieve them through 100-200 mesh sieves for 3 times respectively. Reagents are fully dry-mixed;

[0036] (3) Put the weighed shellac into a beaker, add an appropriate amount of 95% ethanol to dissolve it, and after the shellac is completely dissolved, pour the dry-mixed uniform agent described in step (2) into the beaker, and stir thoroughly. Dry the medicine in a cool place until there is no liquid;

[0037] (4) Scrape the dried agent described in step (3) out of the beaker, pour it on an 18-mesh granulation sieve for granulation, and then put it in an oven at 60-70°C for drying;

[0038] (5) Pour the dried medicament described in step (4) into a sieve with a mesh size of 100-200 and ...

Embodiment 3

[0041] (1) Weigh 40 parts of quantitative ammonium perchlorate, 38 parts of metaldehyde: 15g of copper chloride: 7g of shellac according to the formula ratio;

[0042] (2) Fully grind the weighed ammonium perchlorate, metaldehyde, and copper chloride in a mortar, respectively, and sieve them through 100-200 mesh sieves for 3 times respectively. Reagents are fully dry-mixed;

[0043] (3) Put the weighed shellac into a beaker, add an appropriate amount of 95% ethanol to dissolve it, and after the shellac is completely dissolved, pour the dry-mixed uniform agent described in step (2) into the beaker, and stir thoroughly. Dry the medicine in a cool place until there is no liquid;

[0044] (4) Scrape the dried agent described in step (3) out of the beaker, pour it on an 18-mesh granulation sieve for granulation, and then put it in an oven at 60-70°C for drying;

[0045] (5) Pour the dried medicament described in step (4) into a sieve with a mesh size of 100-200 and sieve it again...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com