Online cutting and breaking-off mechanism for glass door sheet

A door panel and glass technology, applied in the field of cold glass cutting, can solve the problems of high scrap rate, high correlation of workers' personal skills, and inability to meet the scale production, and achieve the effect of fixed and reliable, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

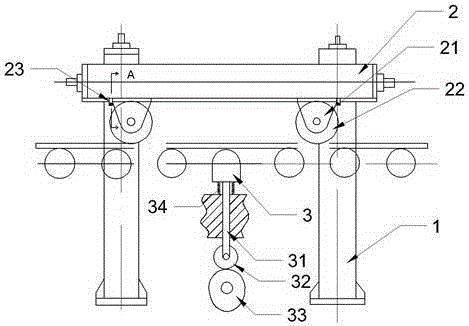

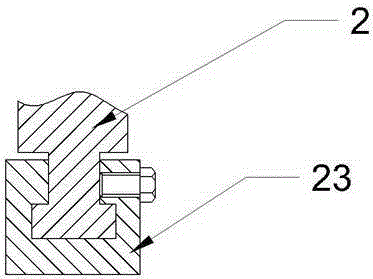

[0014] The reference numerals in the accompanying drawings include: frame 1, crossbeam 2, pressure wheel seat 21, inflation pressure wheel 22, limit block 23, top hammer 3, ejector rod 31, pulley 32, cam 33, extension spring 34.

[0015] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0016] The on-line cutting and breaking mechanism of the glass door panel in the present embodiment comprises a frame 1, an inflatable air wheel 22, and a push rod 31. A crossbeam 2 is installed on the frame 1, and the inflatable air wheel 22 is located at two ends of the crossbeam 2. A push rod 31 is arranged below.

[0017] A chute is planed on the beam 2, and a corresponding slider is processed on the pressure roller seat 21, and the slider is located in the chute to cooperate with it. The pressure roller seat 21 can slide on the beam 2, and the inflati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com