A Marine Seawater Desalination System Based on Diesel Engine Waste Heat Recovery

A waste heat recovery system and waste heat recovery technology, applied in seawater treatment, general water supply conservation, water/sewage treatment, etc., can solve the problems of ships unable to effectively use energy and low energy utilization efficiency, and achieve simple structure, convenient operation, and avoidance. fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

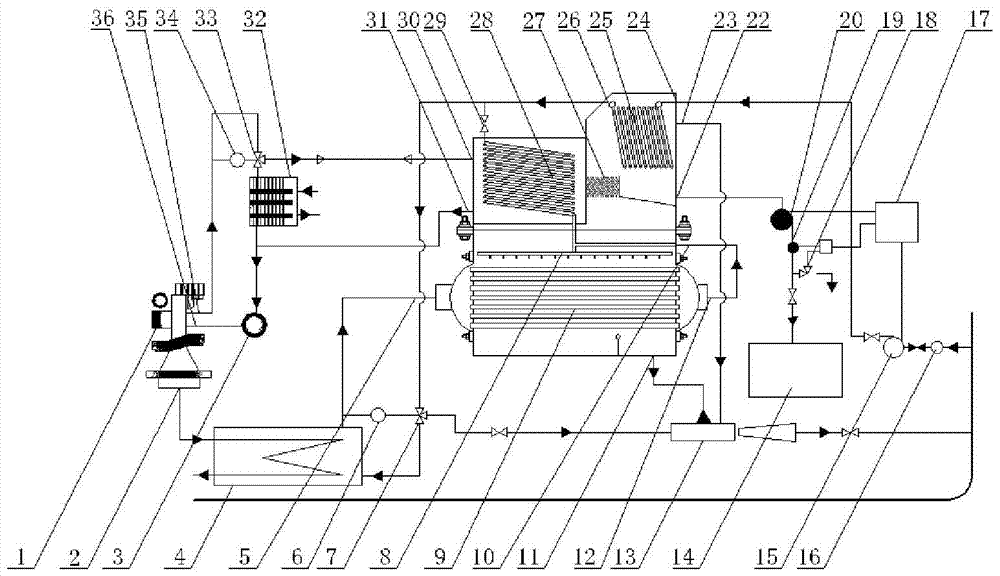

[0021] In order to better illustrate the present invention, further description will be given below in conjunction with the accompanying drawings.

[0022] A marine seawater desalination system based on diesel engine waste heat recovery of the present invention includes a diesel engine waste heat recovery system, a distillation system, a fresh water collection system and a vacuum system.

[0023] The diesel engine waste heat recovery system includes a flue gas waste heat recovery system and a cylinder liner cooling water waste heat recovery system. The flue gas waste heat recovery system is respectively connected with the distillation system and the vacuum system; the cylinder jacket cooling water waste heat recovery system is connected with the distillation system; the distillation system is connected with the fresh water collection system. The flue gas waste heat recovery system includes a hot water pool 4; one end of the hot water pool 4 is connected to the diesel engine fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com