Automatic cable transfer system

A technology of automatic transmission and cable transmission, which is applied in the directions of cable laying equipment, transportation and packaging, and delivery of filamentous materials, etc. problems, to achieve the effect of reducing the use of cranes and labor, broad practical and market prospects, and reducing manpower input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

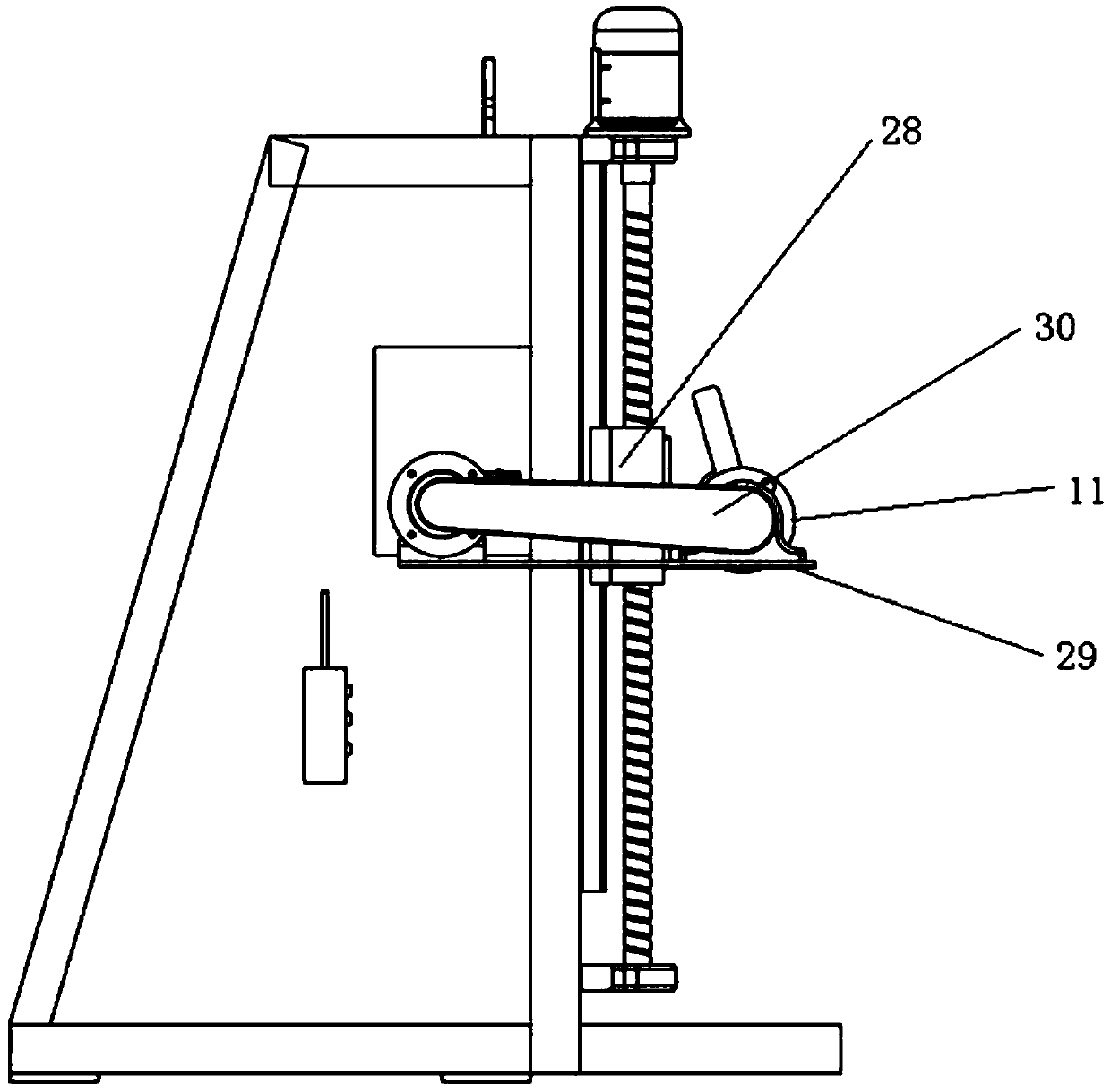

[0033] Such as figure 1As shown, the automatic cable transmission system includes a general controller, a cable reel 1, an automatic portable cable transmission robot 4, a metal wire sheath 5, a steel wire rope 6, a synchronous positioning traction device 7, an automatic cable lifting and laying device 8 and a bracket 9 A cable reel 1 is installed on the automatic cable lifting and laying device 8, a bracket 9 is placed on the side of the automatic cable lifting and laying device 8, and several automatic portable cable transmission robots 4 and a synchronous positioning traction device 7 are fixed on the bracket 9 in turn. , a cable roller 3 is arranged between two adjacent automatic portable cable transmission robots 4, and the cable roller 3 is fixed on the bracket 9. When two adjacent automatic portable cable transmission robots 4 are far away, the cable 2 is transmitted on the cable roller 3, which avoids the cable 2 being dragged on the bracket 9 and cannot be moved. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com