Steel-lining nylon carrier roller

A nylon and roller technology, applied in the direction of rollers, conveyor objects, transportation and packaging, can solve the problems of inability to carry weight, insufficient strength, lack of rigidity, etc., to ensure anti-corrosion and dust-proof performance, and improve the bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

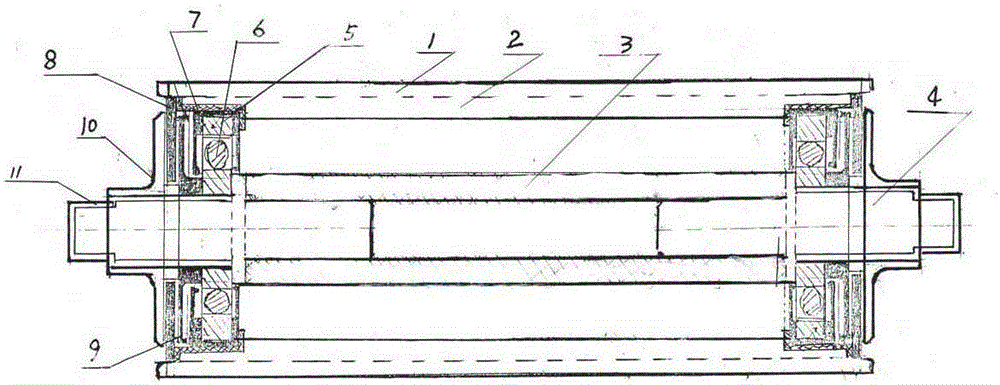

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] As shown in the figure, the steel-lined nylon idler roller of the present invention is composed of a through shaft, a roller and two rolling bearing assemblies.

[0015] The drum has a two-layer structure, the outer layer is a reinforced nylon outer cylinder 1, and the inner layer is a steel pipe lining 2. The inner lining of the steel pipe increases the bearing strength of the roller, and the steel pipe is wrapped with nylon, which not only has high corrosion resistance, but also has a rigid bearing capacity.

[0016] The rolling bearing assembly is composed of a rolling bearing 5, a bearing anti-corrosion shell 7, and a bearing sealing cover 8. The inner ring of the rolling bearing is fixedly set on the through shaft; the anti-corrosion shell of the bearing is ring-shaped, which is set on the outer ring of the rolling bearing and partially seals the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com