Demolding device for glass

A demoulding device and demoulding technology, applied in the distribution of plane items, etc., can solve the problems of small glass gap, no place to lower force, and smaller storage tank spacing, etc., to achieve the effect of asynchronous jacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

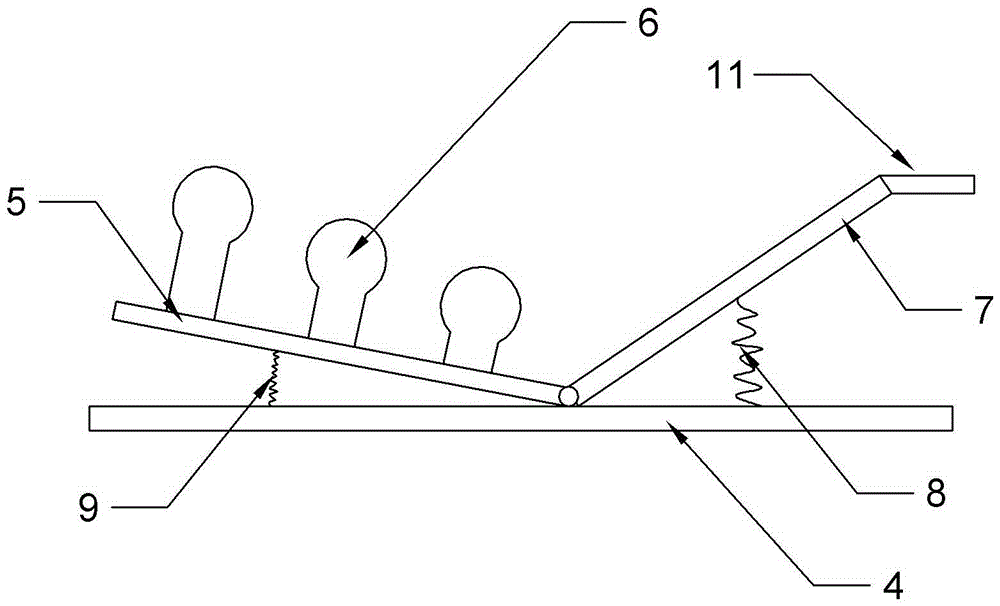

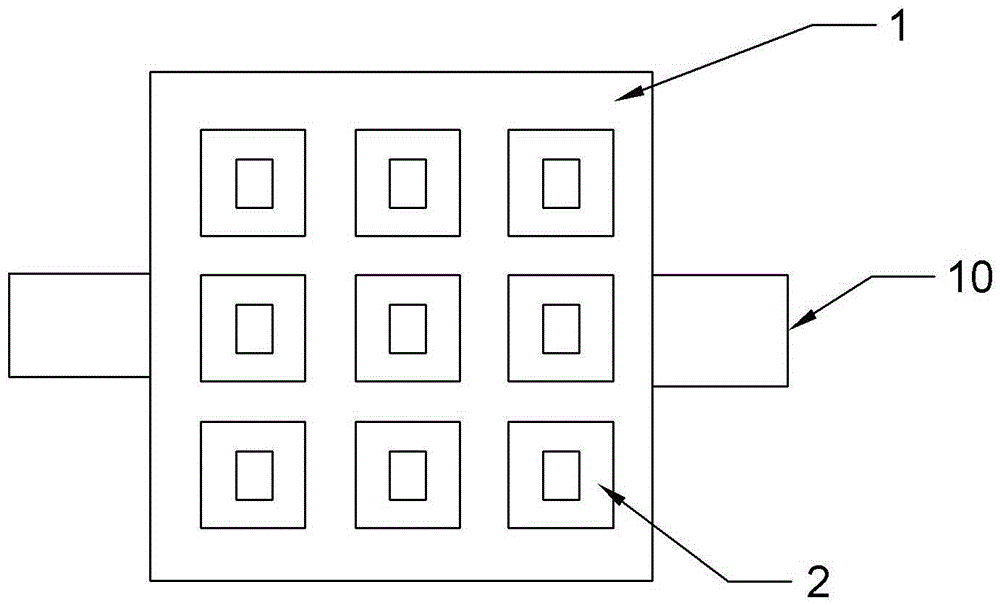

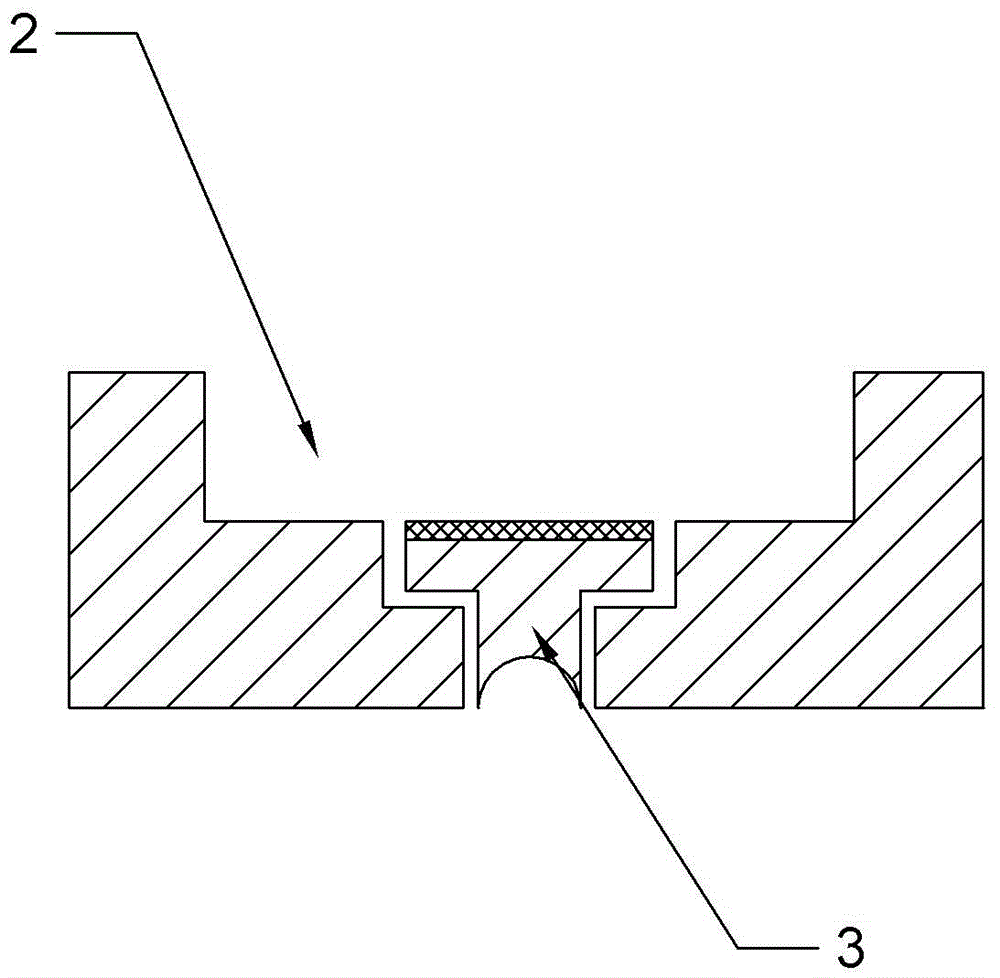

[0018] Such as figure 1 As shown, a demoulding device for glass includes a demoulding body, the demoulding body includes a bracket 4, a demoulding part and a power part, the bracket 4 is located under the demoulding part, and the demoulding part includes a support plate 5 and a The plurality of stripping modules 6 on the support plate 5 are arranged horizontally and vertically, the gap between the stripping modules is 0.1-0.5cm, and the heights of the stripping modules 6 at the end away from the power part decrease in order, and the heights are 3cm respectively. 2cm, 1.5cm. The power part is a seesaw 7, and the end of the seesaw is provided with a pedal 11 away from the support plate, which is convenient for stepping on. A spring 8 is arranged below the seesaw 7 , and the end of the seesaw 7 is hinged with the support plate 5 . A compression spring 9 is arranged below the support plate 5 , and the support plate 5 and the bracket 4 are connected through the compression spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com