Multi-type welding processing and manufacturing technological method for full-automatic welding robot

A technology of fully automatic welding and welding robots, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems such as poor versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

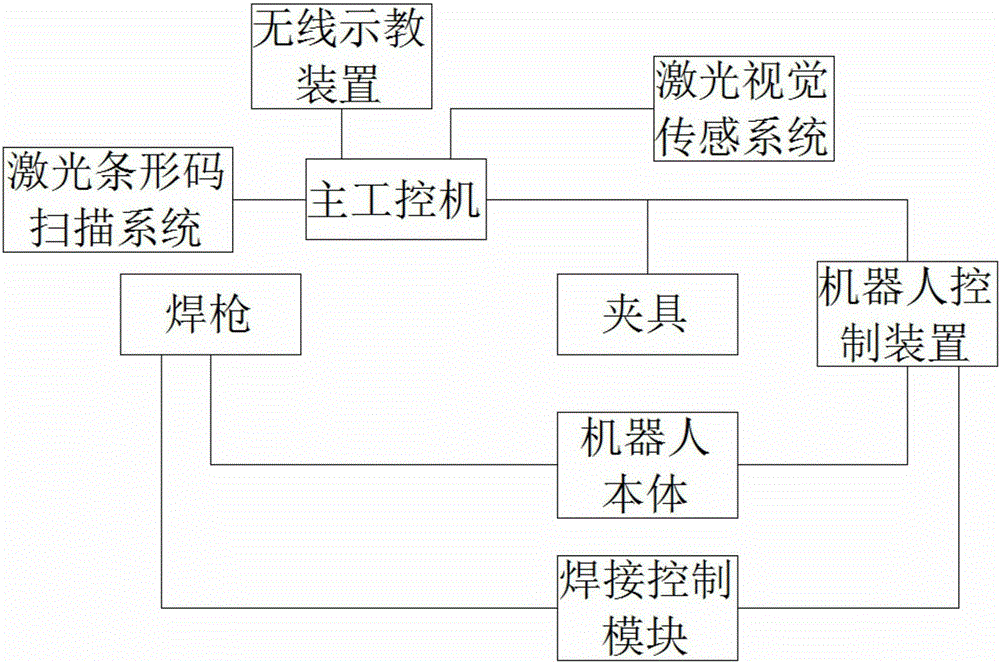

[0045] The invention discloses a multi-type welding processing and manufacturing process method for a fully automatic welding robot. The welding robot includes: a robot body, a welding torch, a fixture, a robot control device, and a main industrial computer; the robot body is connected to a welding torch and a robot control device. , the main industrial computer connects the fixture and the robot control device;

[0046]The welding robot also includes: an initialization module, a zero confirmation module, an address assignment module, a wireless teaching device, a laser vision sensing system, a laser barcode scanning system, a communication module and a welding control module; the initialization module, a zero confirmation module, The add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com