Purification system for rubber exhaust gas in sealing strip production field

A technology of purification system and sealing strip, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, combined devices, etc., to achieve the effect of efficient purification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

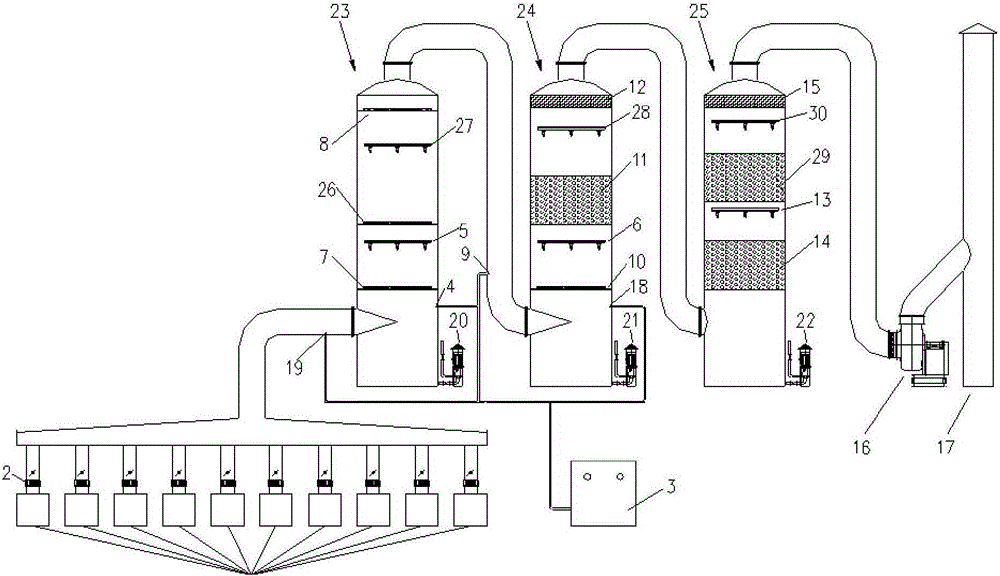

[0042] Such as figure 1 As shown, the rubber waste gas purification system in the field of automobile sealing strip production of the present invention includes multiple sets of gas collecting hoods 1 installed at the waste gas generation station, a swirling water film dust removal tower 23 dedicated to derubberization and removal of carbon black particles, and a dedicated enhanced oxidation decomposition The swirl oxidation tower 24 for the organic components in the waste gas is dedicated to provide the strong oxidant ozone generator 3 for the swirl oxidation tower 24, and it is dedicated to strengthen the terminal deep purification of the decomposition products of the swirl water film dust removal tower 23 and the swirl oxidation tower 24 Tower 25, a circulating water pump unit dedicated to providing media for dust removal and exhaust gas purification, including the first circulating pump 20 connected to the swirling water film dedusting tower 23, the second circulating pump ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com