Method for judging maintenance of times of semiconductor production apparatuses

A technology for manufacturing devices and semiconductors, applied in the field of CVD devices and its purification, can solve the problems of difficult monitoring, clogging of sampling pipes, and difficulty in frequently monitoring the moisture content of corrosive gases, so as to reduce waste and time waste, and achieve high-efficiency purification treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

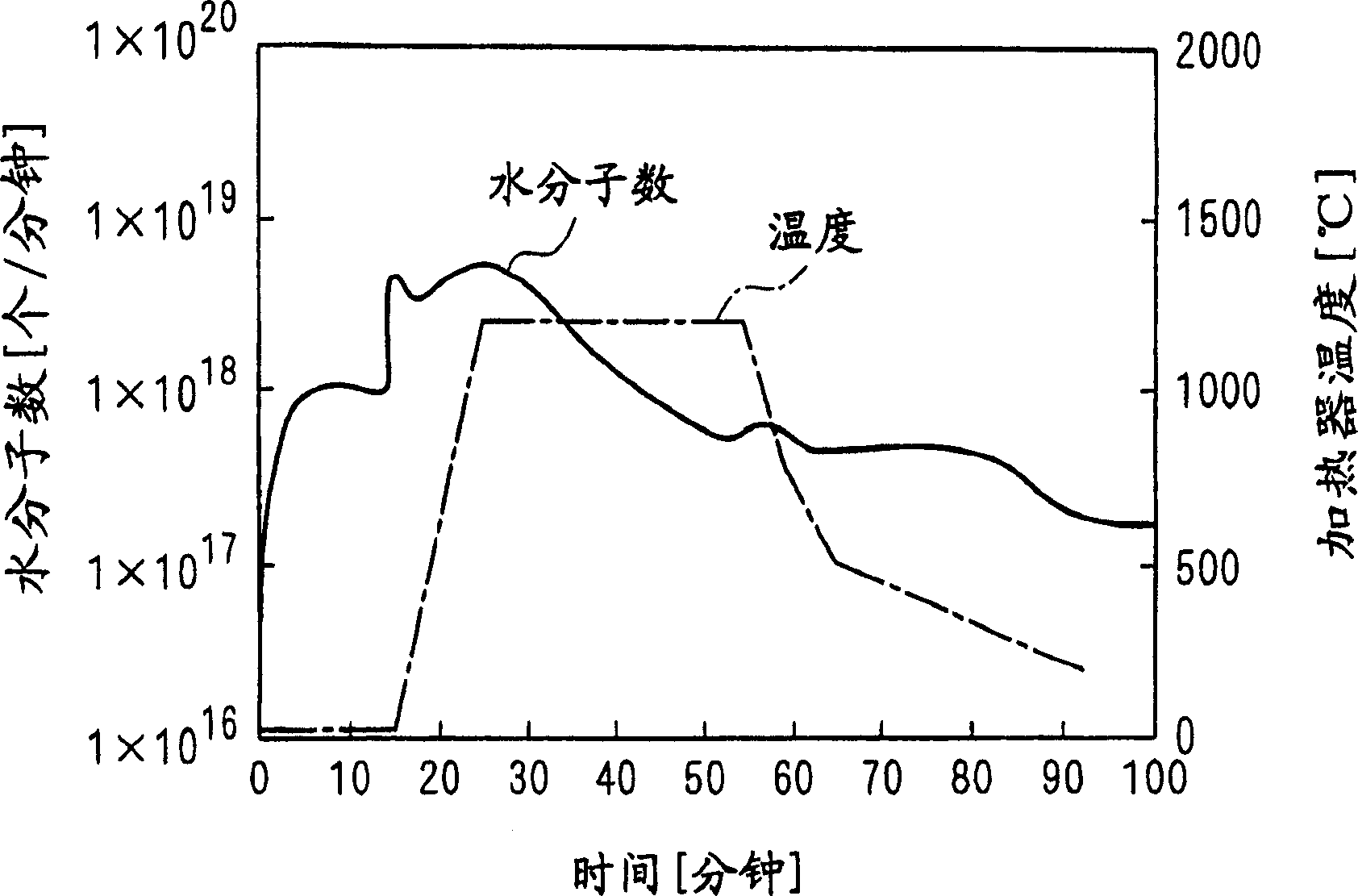

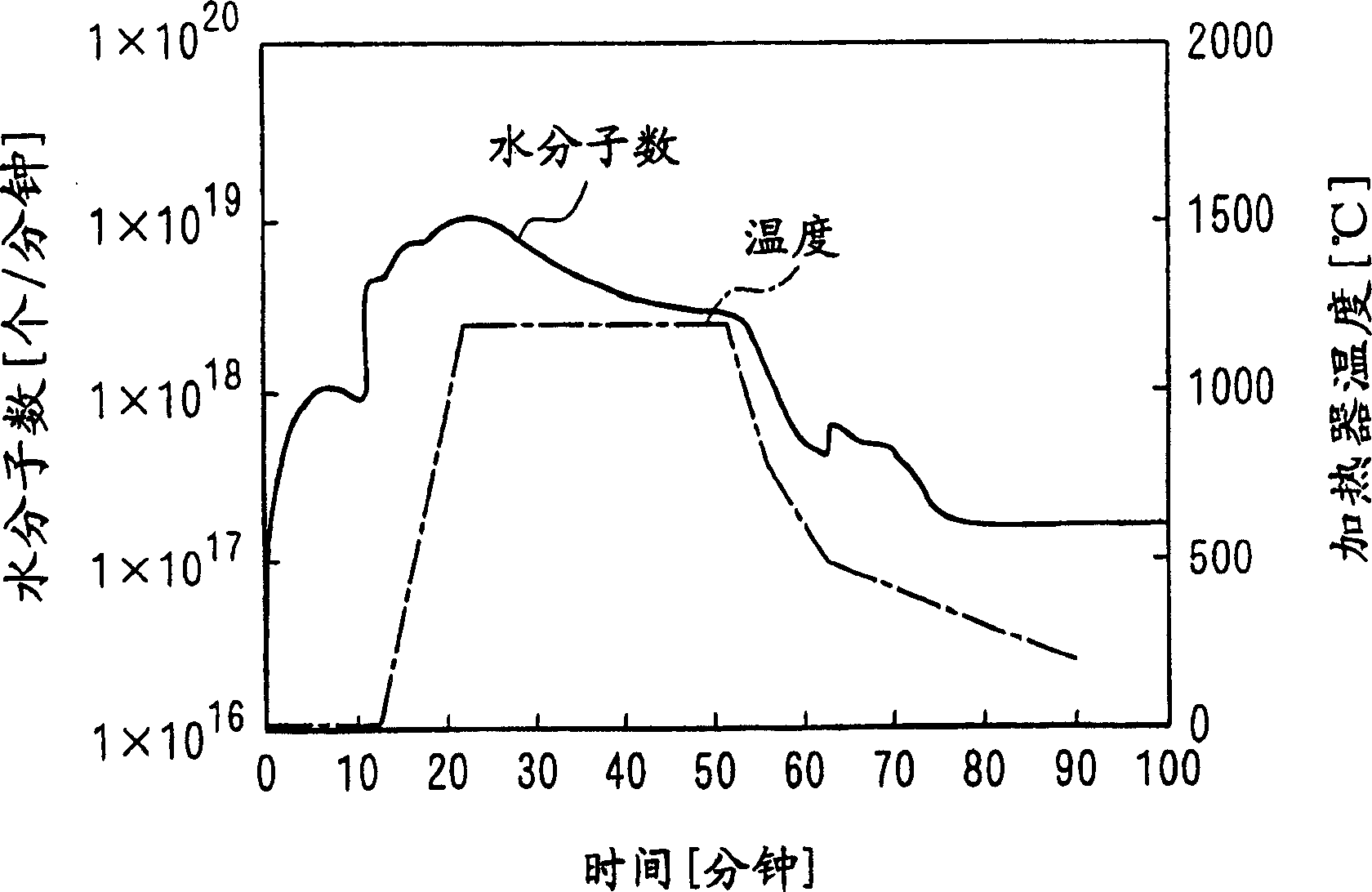

[0051] First, the purification effect of the conventional purification treatment using only an inert gas and the purification treatment using a gas mixture of an inert gas and a gas with a high thermal conductivity was compared. After the moisture concentration in the gas discharged from the reactor 112 is fully purified in advance to 0.1 ppm or less, the door between the reactor 112 and the dry box 113 is opened while nitrogen gas is flowing during the actual film formation operation. 15 minutes of standard time.

[0052] Then, after the door is closed, only nitrogen gas is passed through the reactor 112 as a purge gas, and the discharge amount of water molecules in the exhaust gas is stabilized until the heating wire is heated to 120° C., and the heating of the heating wire is stopped after 40 minutes have elapsed. Heat to lower the temperature slowly. The moisture content in the exhaust gas during this baking and cleaning period was measured. figure 2 Indicates its resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com