Black fungus modifying method and application

A black fungus, modified technology, applied in the field of food processing, to achieve the effect of easy breakage, delicate taste and high processing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for modifying black fungus. The specific method is to remove the impurities in the black fungus, soak it in an aqueous solution containing 2.0% soluble starch for 2.0 hours after initial washing, and obtain the foamed black fungus; soak the black fungus Spin dry at 1000rpm / min for 1.0min, gradually raise the temperature to 55°C, dry the black fungus until the water content is 15%, and obtain the dried black fungus; take out the dried black fungus and put it into a pressure vessel to dry Black fungus accounts for 25% of the volume of the pressure vessel. After sealing the vessel, heat it to 120°C, pressurize it to 0.5MPa, then quickly release the pressure to normal pressure, and then dry it at 90°C until the water content is lower than 3%. Black fungus.

[0039]This example provides a preparation method of modified black fungus superfine powder. The specific method is: remove the impurities in the black fungus, soak it in an aqueous solu...

Embodiment 2

[0042] This embodiment provides a method for modifying black fungus. The specific method is to remove the impurities in the black fungus, soak it in an aqueous solution containing 3.0% soluble starch for 3.0 hours after initial washing, and obtain the foamed black fungus; soak the black fungus Spin dry at 2000rpm / min for 1.0min, gradually raise the temperature to 50°C, dry the black fungus to a water content of 15%, and obtain the dried black fungus; take out the dried black fungus and put it into a pressure vessel to dry Black fungus accounts for 35% of the volume of the pressure vessel. After sealing the vessel, heat it to 140°C, pressurize it to 0.7MPa, then quickly release the pressure to normal pressure, and then dry it at 80°C until the water content is lower than 3%. Black fungus.

[0043] This example provides a preparation method of modified black fungus superfine powder. The specific method is: remove the impurities in the black fungus, soak it in an aqueous solution...

Embodiment 3

[0046] This embodiment provides a method for modifying black fungus. The specific method is to remove the impurities in the black fungus, soak it in an aqueous solution containing 5.0% soluble starch for 6 hours after initial washing, and obtain the soaked black fungus; soak the black fungus in Dry at 5000rpm / min for 0.2min, gradually heat up to 65°C, dry the black fungus until the water content is 20%, and obtain the dried black fungus; take out the dried black fungus and put it into a pressure vessel to make the dried black fungus The fungus accounts for 20% of the volume of the pressure vessel. After sealing the vessel, heat it to 130°C, pressurize it to 0.6MPa, then quickly release the pressure to normal pressure, and then dry it at 90°C until the water content is lower than 3%. Black Fungus.

[0047] This example provides a preparation method of modified black fungus superfine powder. The specific method is: remove the impurities in the black fungus, soak it in an aqueous...

PUM

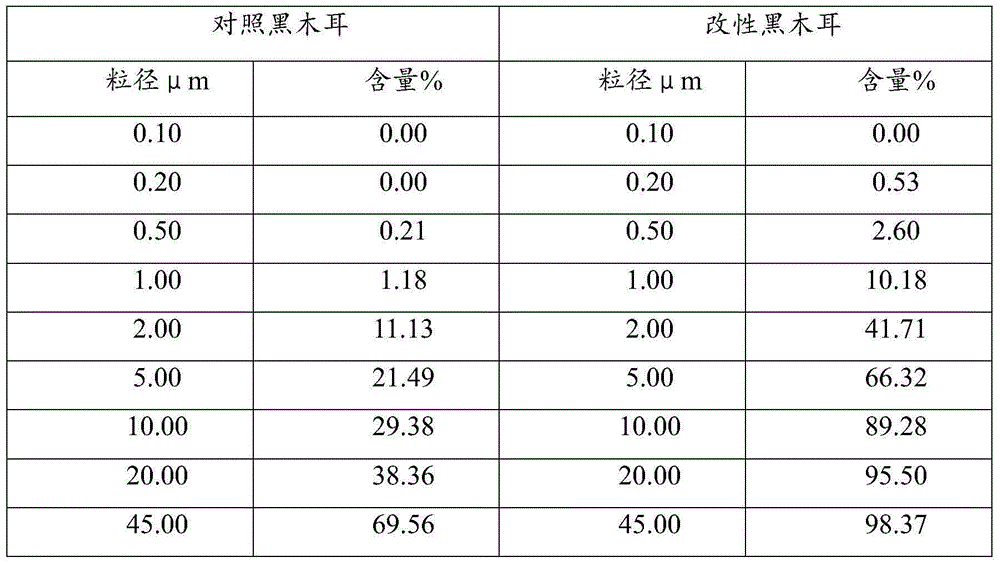

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com