Front-installed soil-loosening operation head and operation method thereof

A technology of working head and guide wheel mechanism, which is applied in agriculture, tillage equipment, agricultural machinery and equipment, etc., can solve the problems of affecting the effect of loosening, adjusting the working position of the loosening knife, reducing the efficiency of loosening, etc., so as to improve the loosening effect. Efficiency and loosening effect, volume reduction, effect of reducing design volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

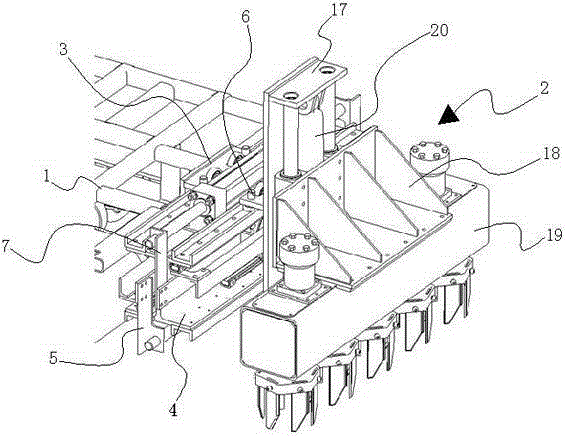

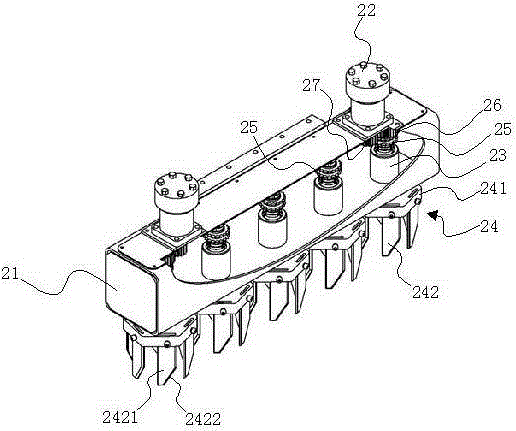

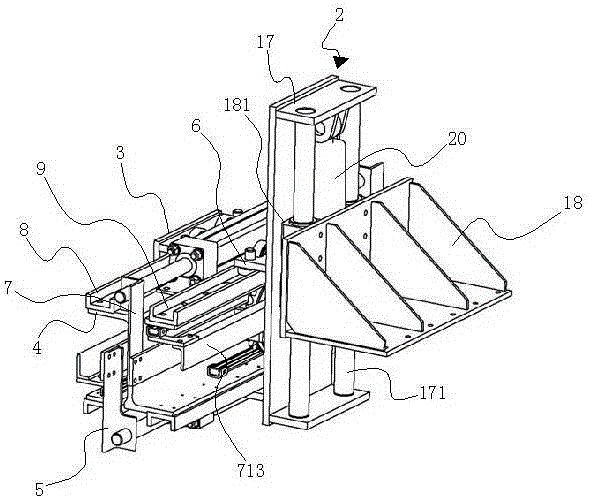

[0041] Example: such as Figure 1 to Figure 3 As shown, a front loosening operation head includes an operation head moving mechanism and an end operation head 2 arranged on a vehicle body chassis 1, and the operation head moving mechanism includes a guide wheel mechanism 1, a moving beam 4, and a lateral movement Drive mechanism one 5, guide wheel mechanism two 6 and laterally moving drive mechanism two 7; the guide wheel mechanism one 3 is fixedly connected to the chassis 1 of the car body, and a transverse guide rail one is fixedly connected to one side of the moving beam 4 8. The moving beam 4 is slidably connected to the vehicle body chassis 1 through the cooperation of the guide wheel mechanism 3 and the transverse guide rail 1 , and the lateral movement driving mechanism 1 5 is arranged on one side of the moving beam 4 and the vehicle body chassis 1, under the drive of the first lateral movement drive mechanism 5, the movable crossbeam 4 can move back and forth along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com