Nickel-zinc ferrite/polyacrylic acid nano-composite material and preparation method thereof

A nano-composite material, nickel-zinc ferrite technology, applied in the magnetic field of inorganic materials, organic materials/organic magnetic materials, etc., can solve the problems of easy magnetization, easy demagnetization, low saturation magnetization, etc. The effect of simplicity, low preparation cost, and high soft magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

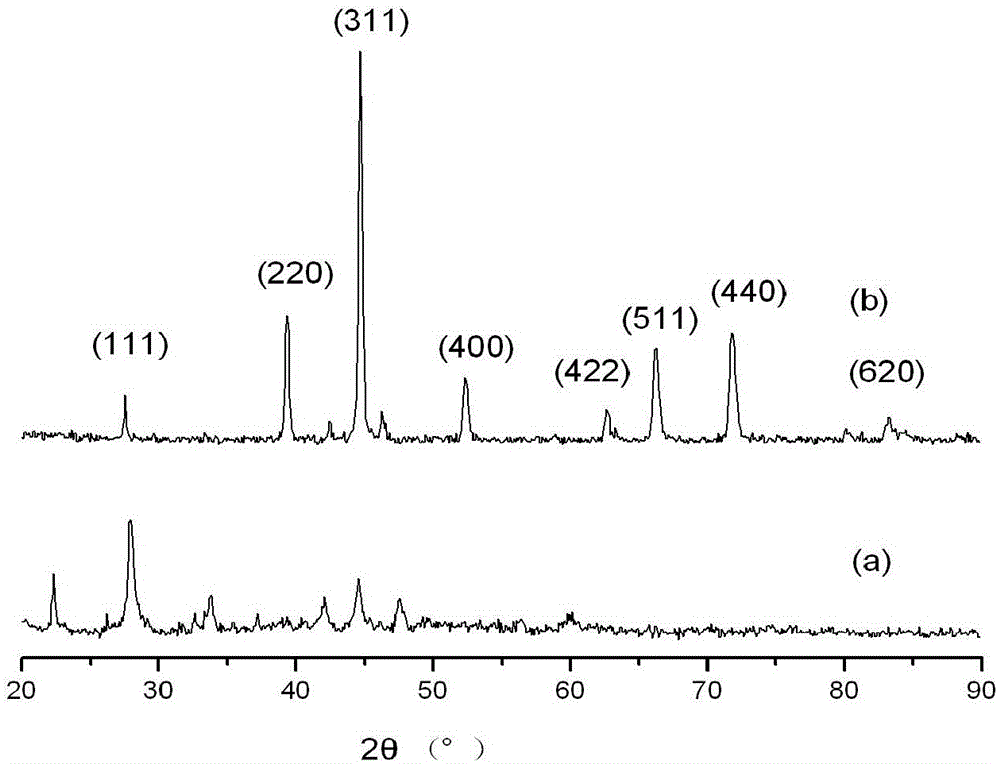

Image

Examples

preparation example Construction

[0023] The preparation method of nickel-zinc-iron / polyacrylic acid nanocomposite of the present invention, comprises the steps:

[0024] (1) According to Ni 0.1~1 Zn 0.1~1 Fe 1~3 o 2~6 The stoichiometric ratio is 0.1~1:0.1~1:1~3, respectively weigh nickel sulfate, zinc sulfate, and ferrous sulfate to prepare metal salt solution, configure ammonium oxalate solution with a concentration of 0.5~1.5mol / L, and the ammonium oxalate After the solution is heated to 30-50°C, a metal salt solution is added thereto, wherein the volume ratio of the ammonium oxalate solution to the metal salt solution is 2:1, and then the mixed solution is kept warm and stirred, preferably, Ni 0.1~1 Zn 0.1~1 Fe 1~3 o 2~6 The stoichiometric ratio is 0.5~1:0.5~1:2~3.

[0025] (2) Regulating the pH of the mixed solution with 6-8mol / L NaOH solution is 9-12;

[0026] (3) After the mixed solution is centrifuged to obtain the precipitate, use deionized water and absolute ethanol to clean the precipitate 2...

Embodiment 1

[0031] (1) According to Ni 0.5 Zn 0.5 Fe 2 o 4 The stoichiometric ratio is 0.5:0.5:2, respectively weigh nickel sulfate, zinc sulfate, and ferrous sulfate to prepare metal salt solution, configure ammonium oxalate solution with a concentration of 1.0mol / L, heat the ammonium oxalate solution to 40°C, and It adds a metal salt solution, wherein the volume ratio of the ammonium oxalate solution to the metal salt solution is 2:1, and then heats and stirs the mixed solution.

[0032] (2) Regulating the pH of the mixed solution with the NaOH solution of 7mol / L is 10;

[0033] (3) Centrifuge the mixed solution at a speed of 5000r / min and a time interval of 10min. After obtaining the precipitate, wash the precipitate twice with deionized water and absolute ethanol respectively.

[0034] (4) Dry the washed precipitate under vacuum condition at 60° C. for 24 hours to obtain a ferrite precursor.

[0035] (5) calcining the ferrite precursor at 200°C for 10 hours, then calcining at 800...

Embodiment 2

[0047] The steps are basically the same as in Example 1, except that the mass ratio of nickel zinc ferrite, acrylic acid, initiator, dispersant and crosslinking agent is 0.1:40:0.01:0.5:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com