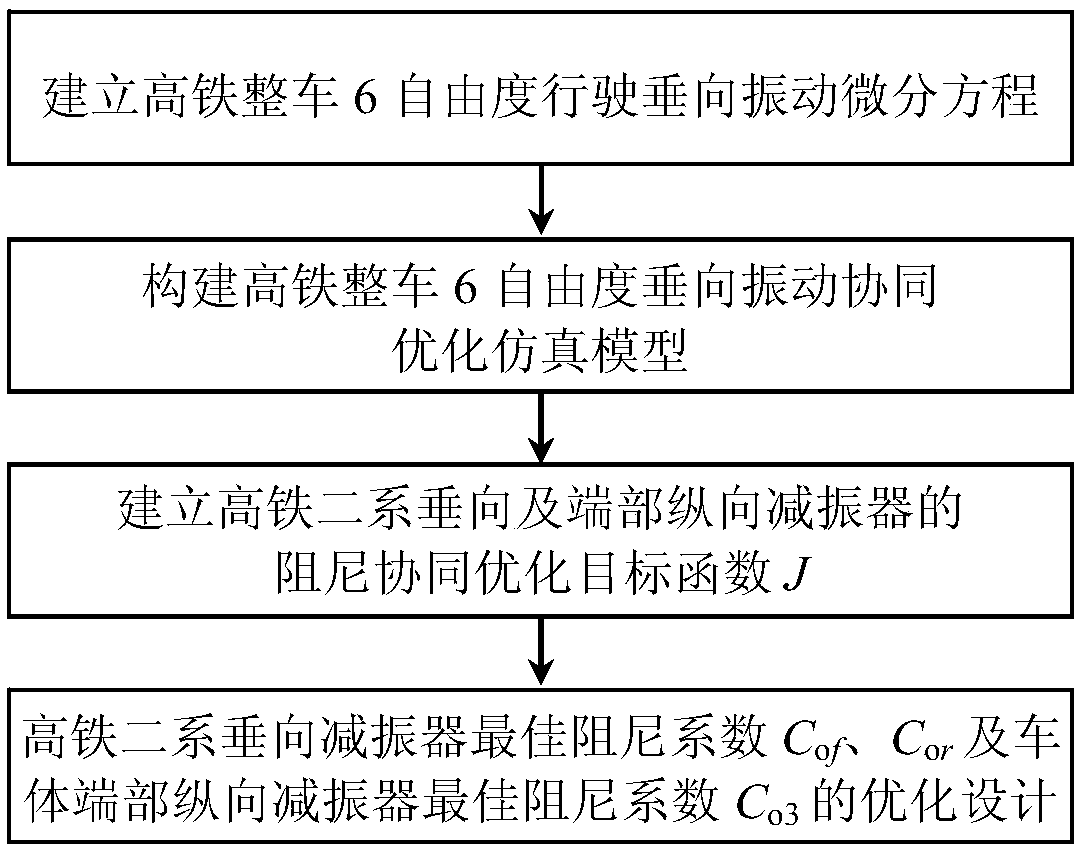

Collaborative optimization method for the damping coefficient of the vertical and end longitudinal shock absorbers of the second series of high-speed railway

An end-longitudinal and secondary-vertical technology, which is applied in the fields of instruments, electrical digital data processing, special data processing applications, etc., can solve the problem that the design requirements of shock absorbers cannot be met, and the theoretical design method and dynamics of the system are not given. Analyze and calculate difficulties and other problems to achieve the effect of shortening product design cycle, improving design level and product quality, and reducing product design and test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

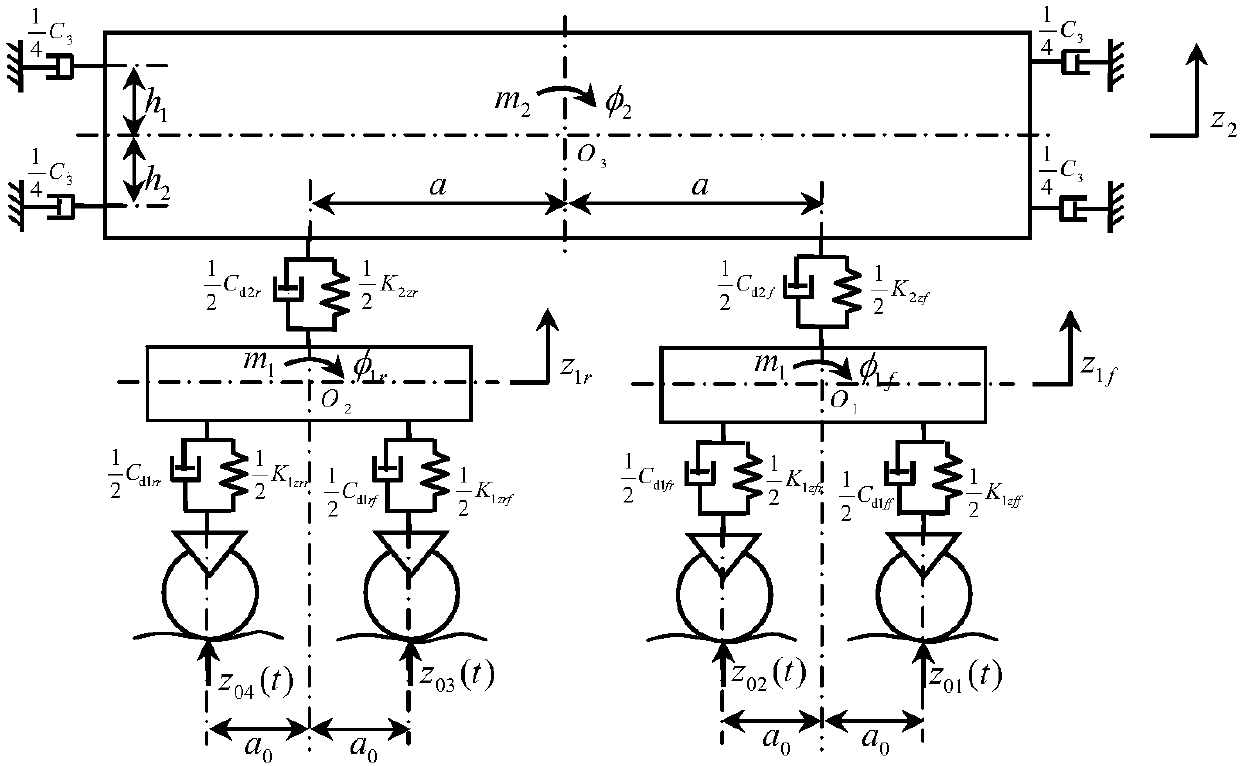

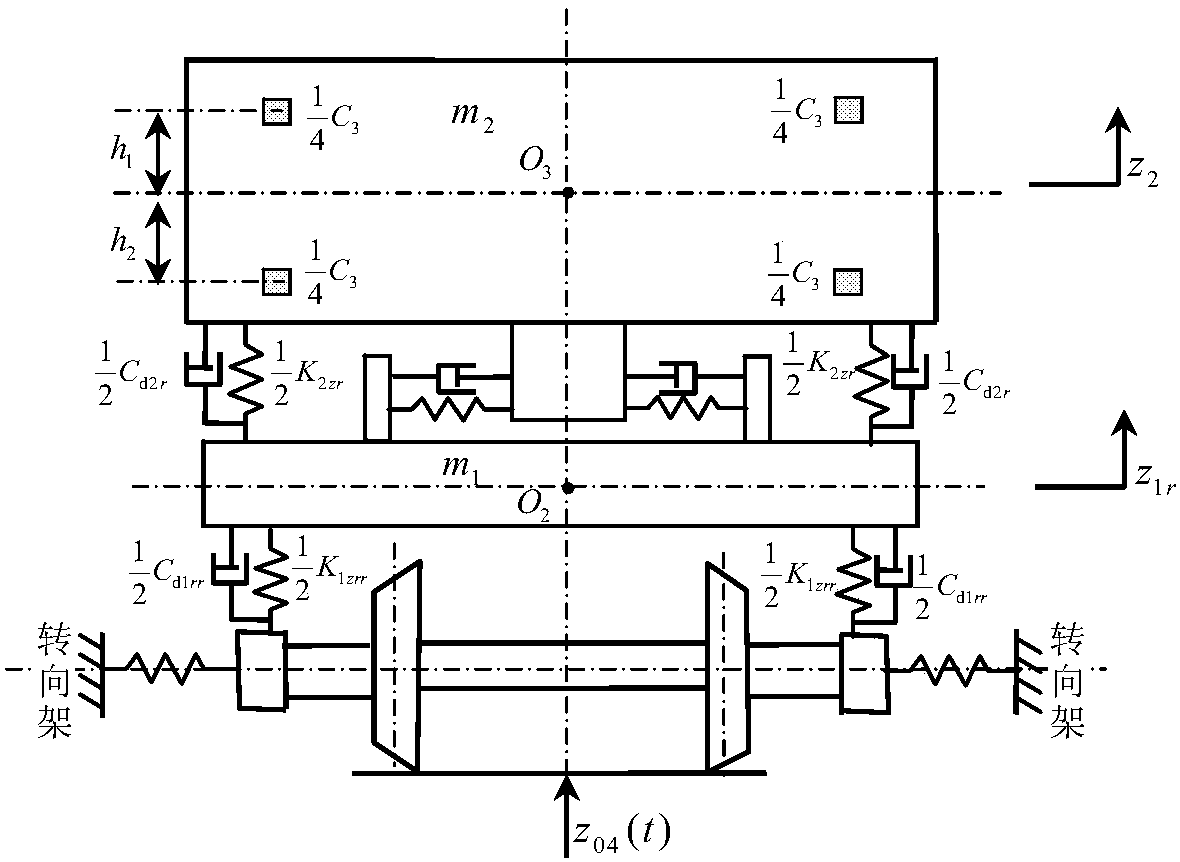

[0032] specific implementation plan

[0033] The present invention will be further described in detail through an embodiment below.

[0034] Two secondary vertical shock absorbers are installed on each bogie of a high-speed railway, and four longitudinal shock absorbers at the end of the car body are installed between two adjacent car bodies, that is, n 1 = 2, n 2 =4; the mass m of its single car body 2 =63966kg, nodding moment of inertia J 2φ =2887500kg.m 2 ; Mass of each bogie frame m 1 =2758kg, nodding moment of inertia J 1φ =2222kg.m 2 ;The vertical equivalent stiffness K of the front suspension of the front bogie 1zff =2.74×10 6 N / m, vertical equivalent damping C d1ff =28.3kN.s / m, the vertical equivalent stiffness K of the primary rear suspension of the front bogie 1zfr =2.74×10 6 N / m, vertical equivalent damping C d1fr =28.3kN.s / m; The vertical equivalent stiffness K of the primary front suspension of the rear bogie 1zrf =2.74×10 6 N / m, vertical equivalent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com