A method for calibrating the magnification of the miniature objective lens of direct-writing lithography machine

A calibration method and lithography machine technology, applied in the direction of microlithography exposure equipment, optics, optical components, etc., can solve the problems of difficult projection optical path magnification and large calibration error, and achieve the effect of easy implementation and high calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

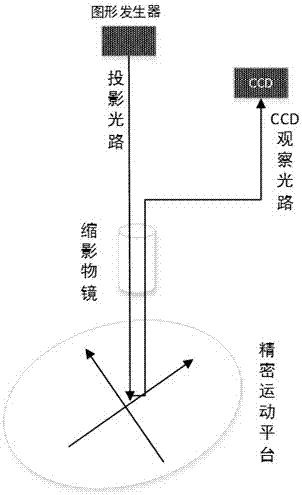

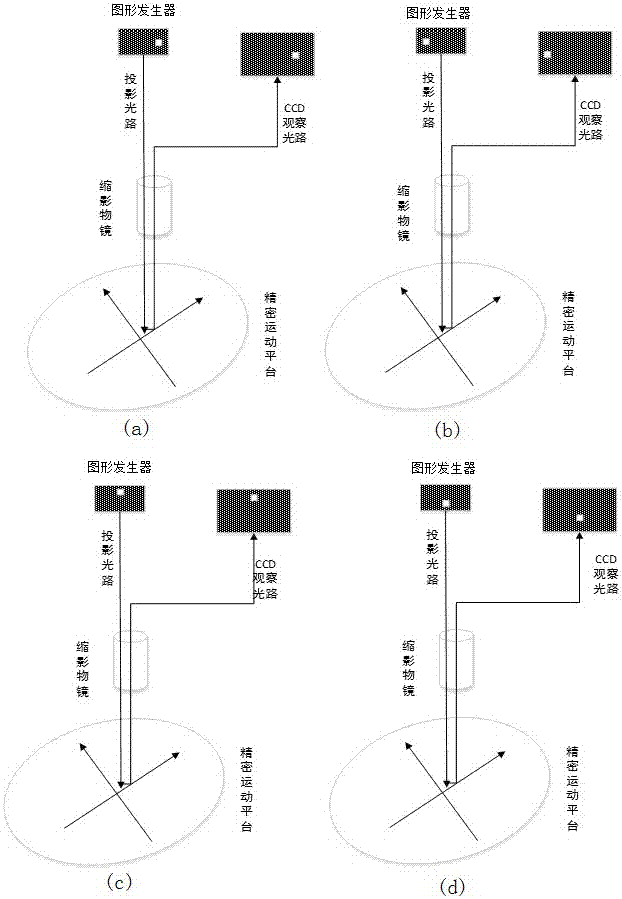

[0036] like Figure 1 ~ Figure 4 As shown, a method for calibrating the magnification of the miniature objective lens of a direct-writing lithography machine comprises the following steps:

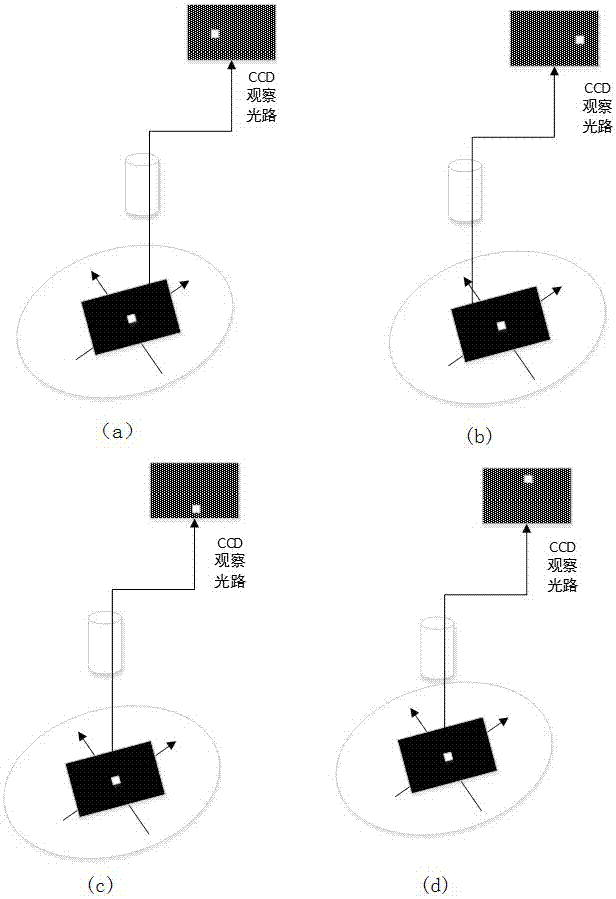

[0037] S1. Select a mask plate (Mask1) with a marking pattern (Mark1) and place it on the base installed on the precision motion platform, and keep it fixed.

[0038] S2. Make sure that the marked figure (Mark1) can be observed from the CCD field of view.

[0039] S3. The precision motion platform is moved along the X-axis and Y-axis respectively for a fixed distance to ensure that the moved mark figure (Mark1) is still within the field of view of the CCD.

[0040] S4. For the mark pattern (Mark1) in the field of view of the CCD, the moving distance is captured by machine vision, and the mark pattern (Mark1) on the substrate can be calculated through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com