Universal test fixture for surface mounted technology (SMT)-based diode components

A general-purpose testing and surface-mounting technology, which is applied in the direction of the measuring device casing, can solve the problems of increased production cost, extended test cycle, and low production efficiency, and achieves the effects of low cost, reduced test cycle extension, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

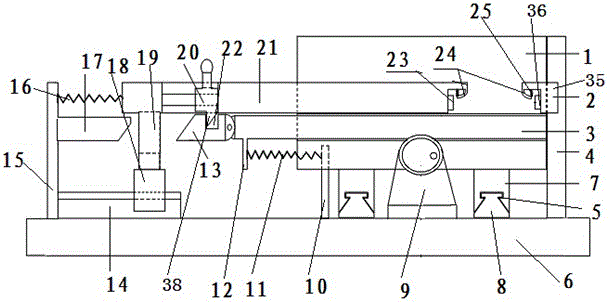

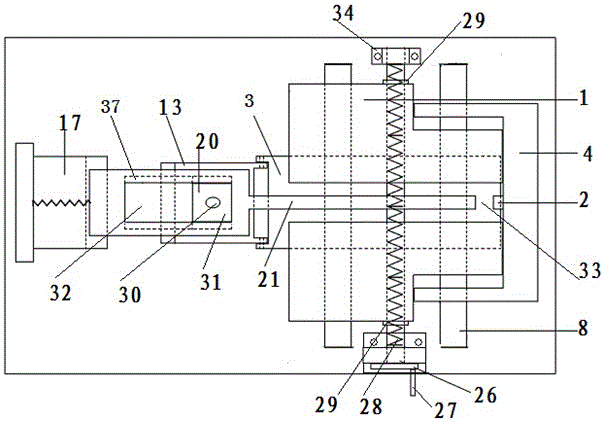

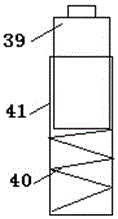

[0018] The invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

[0019] like Figure 1~Figure 3 As shown, a general test fixture for surface mount two-pole components includes a front and rear sliding positioning slider 1, an elastic test probe module 2 and a pull-out base plate 3, and the front and rear sliding positioning slider 1 adopts two sliders The front and back are symmetrically placed, and the screw nut set at the bottom drives the two sliders to move toward each other, and is connected to the guide rail pair 5, and a movable drawer bottom plate 3 is arranged near the bottom, and the drawer base plate 3 is embedded in the sliding body between the sliders. In the slot, the left end of the drawer bottom plate 3 is connected with a reset device that resets the drawer base plate after being drawn out, and an elastic test probe module 2 is arranged between the two sliders on it, and the elastic test probe modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com