MEMS metal-oxide semiconductor gas sensor and manufacturing method thereof

An oxide semiconductor and gas sensor technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of poor slurry stability, difficult automation of the process, low sensitivity, etc., and achieves low mass manufacturing cost, good product consistency, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

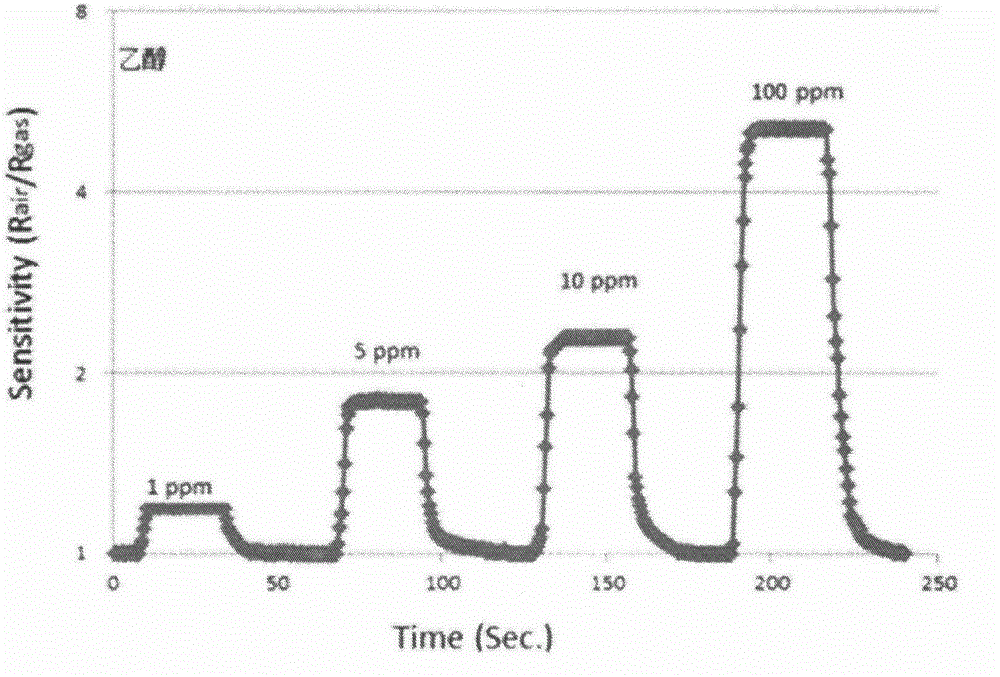

specific Embodiment 1

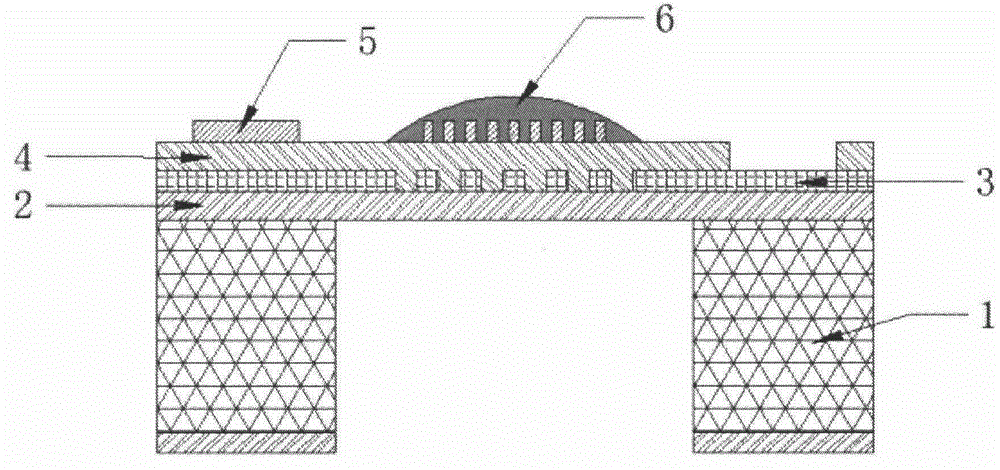

[0030] like figure 2 As shown, the present invention provides a kind of MEMS metal oxide semiconductor gas sensor, and this MEMS metal oxide semiconductor gas sensor comprises MEMS micro-hot plate, and described MEMS micro-hot plate comprises annular monocrystalline silicon substrate 1, supporting layer 2, heating An electrode 3, an insulating layer 4, a sensitive electrode 5, and a sensitive material film 6 coated in the measurement area of the sensitive electrode.

[0031] Wherein, the annular single crystal silicon substrate 1 is formed by photolithography and dry ICP anisotropic etching process on the back of a single crystal silicon wafer. The supporting layer (2) is LPCVDSi 3 N 4formed with a thickness of 500 nm. The heating electrode (3) is Ta20nm / Pt200nm, formed by Liftoff process. The insulating layer (4) is composed of PECVDSiN with a thickness of 500nm. The sensitive electrode (5) is Ta20nm / Pt200nm, formed by sputtering and photolithography. The sensitive m...

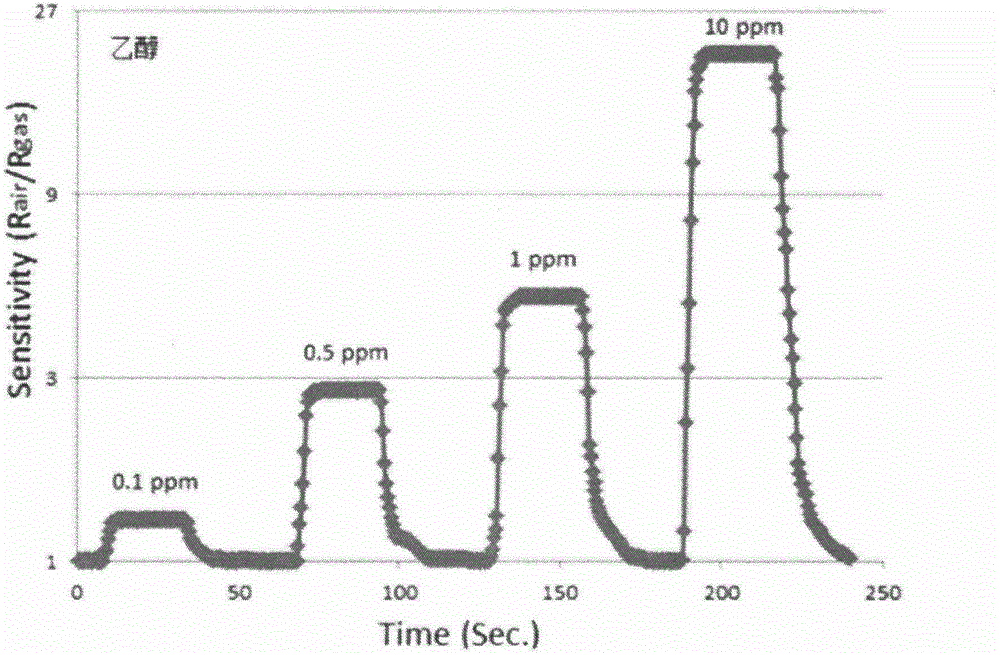

specific Embodiment 2

[0042] Next, a second embodiment of the present invention will be described with reference to the drawings.

[0043] like figure 2 As shown, the MEMS metal oxide semiconductor gas sensor includes a MEMS micro-hot plate, and the MEMS micro-hot plate includes an annular single crystal silicon substrate 1, a support layer 2, a heating electrode 3, an insulating layer 4, a sensitive electrode 5, and a coating Sensitive material film 6 in the sensitive electrode measurement area.

[0044] Wherein, the annular single crystal silicon substrate 1 is formed by photolithography and dry ICP anisotropic etching process on the back of a single crystal silicon wafer. The support layer 2 is LPCVDSi 3 N 4 formed with a thickness of 450 nm. The heating electrode 3 is Ti20nm / Pt200nm, formed by Liftoff process. The insulating layer 4 is composed of PECVDSiN with a thickness of 450nm. The sensitive electrode 5 is Ti20nm / Pt200nm, formed by Liftoff process. The sensitive material film 6 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com