Visual test system for heat transfer and scale inhibition performance of oil sealing water cooler in oil refinery

A technology of oil refining equipment and testing system, which is applied in the field of visual testing system, can solve the problems of large differences in heat transfer performance and resistance performance parameters, and the inability to simulate the fouling of water coolers, etc., so as to achieve easy observation and research, high reliability, The effect of stable test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

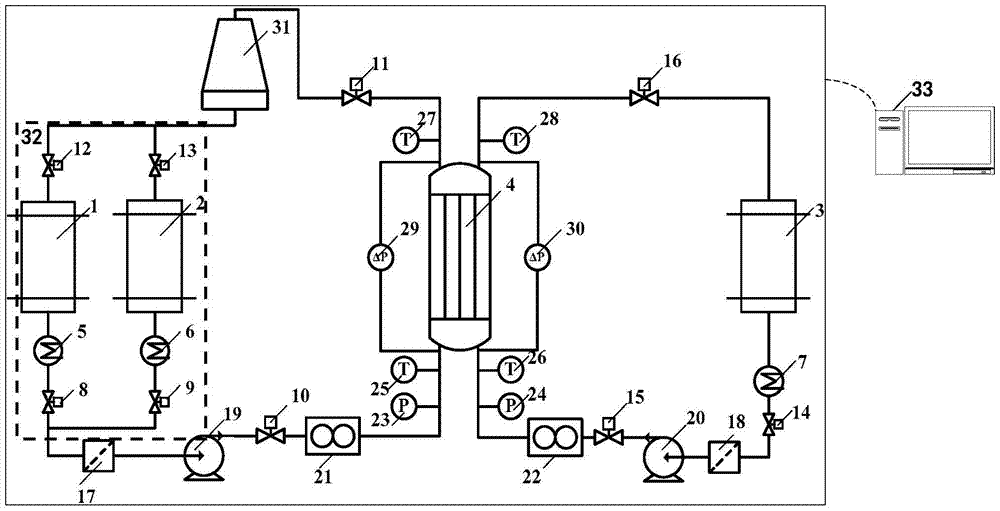

Method used

Image

Examples

example 1

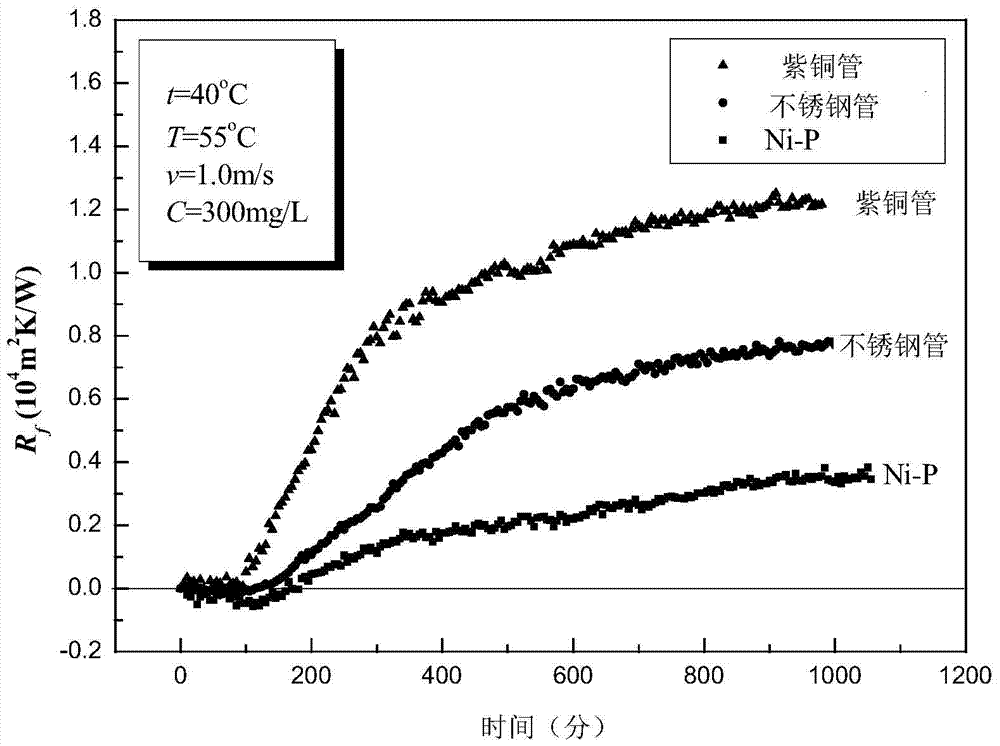

[0075] During the implementation of this example, the types of test heat exchange tubes of the oil seal cooler test assembly 4 were copper plain tubes, stainless steel plain tubes, and Ni-P electroless plated tubes in which the surface of the copper plain tube was used as the base heat exchange tube for electroless plating. Such as image 3 As shown, the fouling curves of the three heat exchange tubes during the induction period, according to the order of copper tubes, stainless steel tubes and Ni-P electroless plating tubes, the fouling induction period is significantly prolonged, respectively 65 minutes, 110 minutes and 180 minutes, The fouling induction period of stainless steel tube and Ni-P electroless plated tube is 1.7 times and 2.8 times that of copper tube, respectively. In the fouling growth stage, the fouling rate of the copper tube is the largest, followed by the stainless steel tube, and the fouling rate of the Ni-P electroless plating tube is the smallest. The fo...

Embodiment example 2

[0077]The test system used in Example 2 is the same as Example 1, and the difference from Example 1 is that the types of test heat exchange tubes in the oil seal cooler test component 4 are stainless steel plain tubes and stainless steel plain tubes as the base tube formed by machining. The special-shaped twisted flat tube is used to measure the heat transfer coefficient in the tube of the sealed oil water cooler and test the simulation component. In this example, indirect fitting is used. First, the flow rate outside the tube is changed under the condition of the maximum flow rate in the tube, and the heat transfer outside the tube is fitted according to the power function. associative. Then change the flow rate in the tube under the condition of the maximum flow rate outside the tube, and calculate the total thermal resistance from the temperature of the inlet and outlet inside and outside the tube and the heat transfer. Deducting the heat transfer resistance outside the tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com