Complex missile-borne cable test system and test method

A cable testing, complex technology, applied in the direction of continuity testing, testing dielectric strength, high resistance measurement, etc., can solve the problems of low efficiency, complexity, and large number of cables in complex cable testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

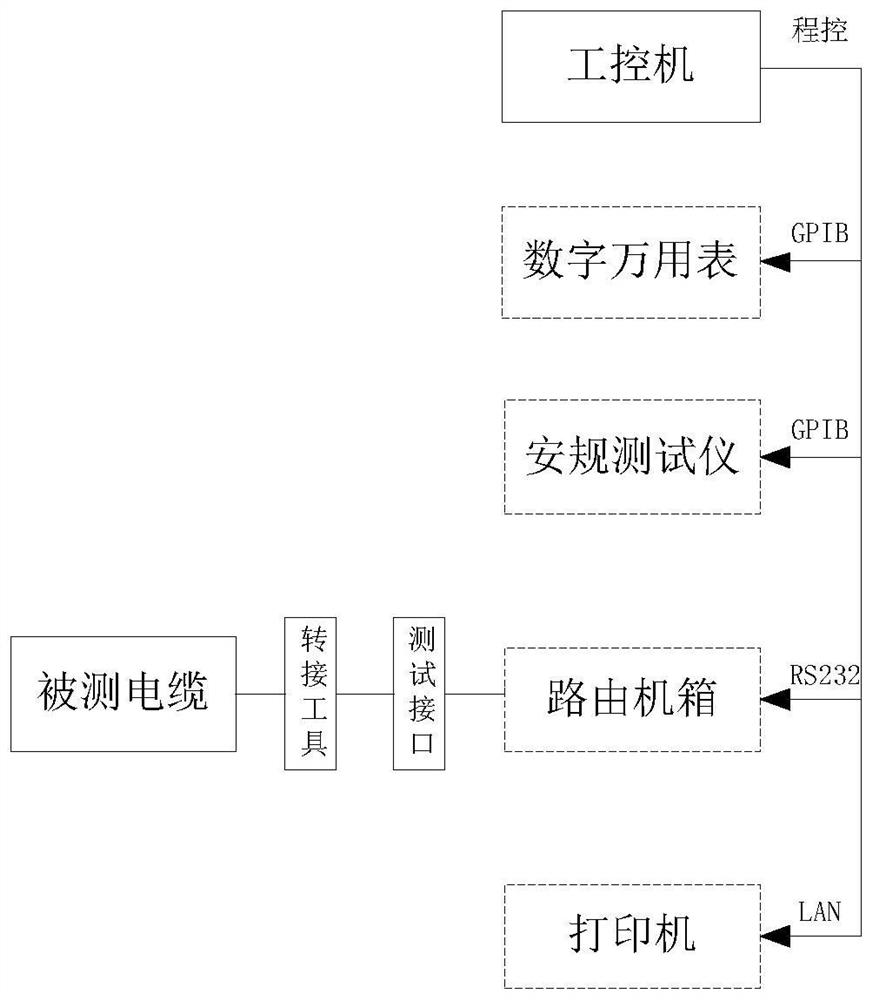

[0032] Such as figure 1 , 2 As shown, the present invention provides a complex spring-on cable testing system, which can be used for factory inspection and acceptance of the spring-on cable, which can be applied to the requirements of production testing, and the test requirement coverage rate is high, realizing multiple test functions and high test efficiency. high.

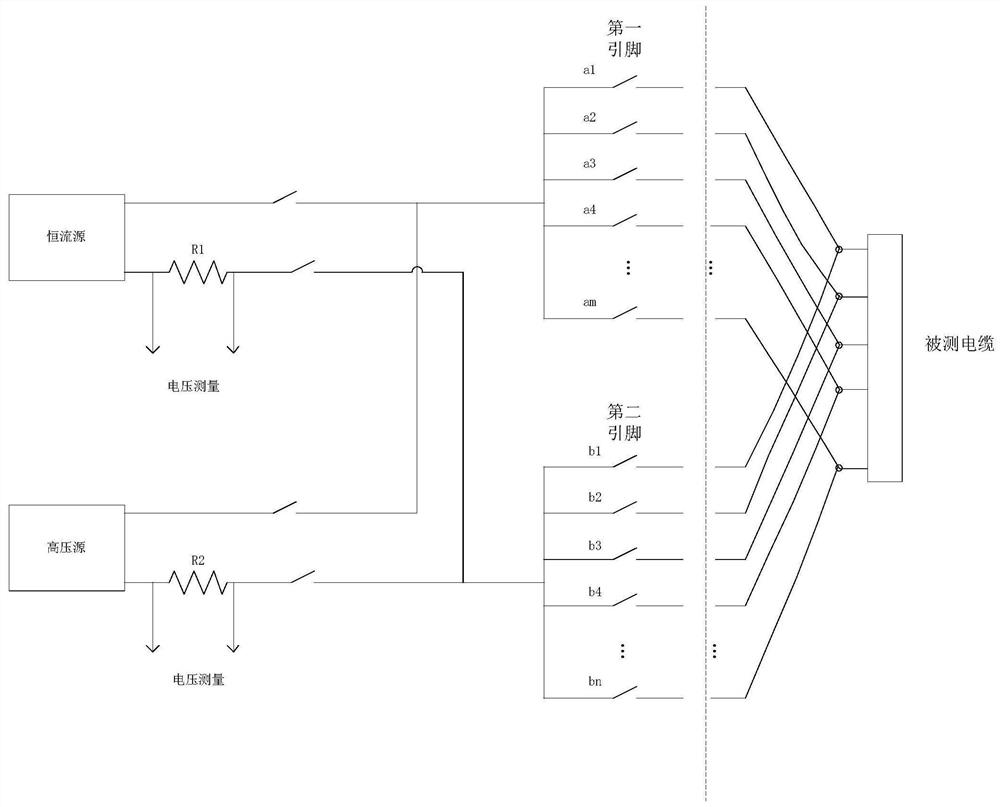

[0033] Specifically, the complex spring-on cable safety test system includes an industrial computer, a routing chassis and a test module. The industrial computer is the control core of the system. It controls other instruments and equipment through various communication interfaces and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com