Ring and block friction abrasion testing machine with abrasion gap adjusting function

A technology of friction and wear test and wear gap, which is applied in the direction of testing wear resistance, etc. It can solve the problems of unable to load the test ring and test block and adjust the gap, and achieve the effect of adjusting the test gap, convenient loading and unloading, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

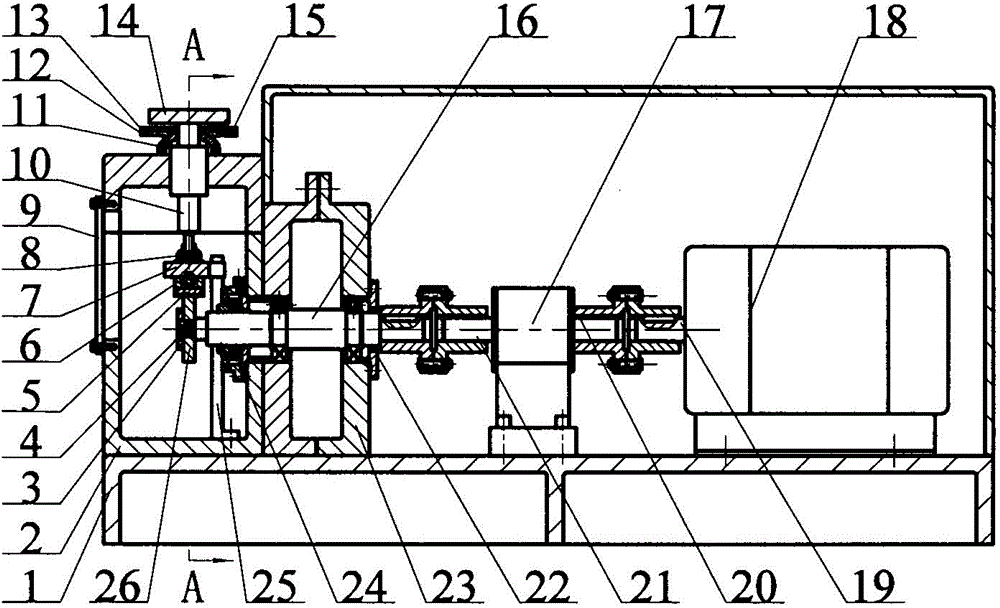

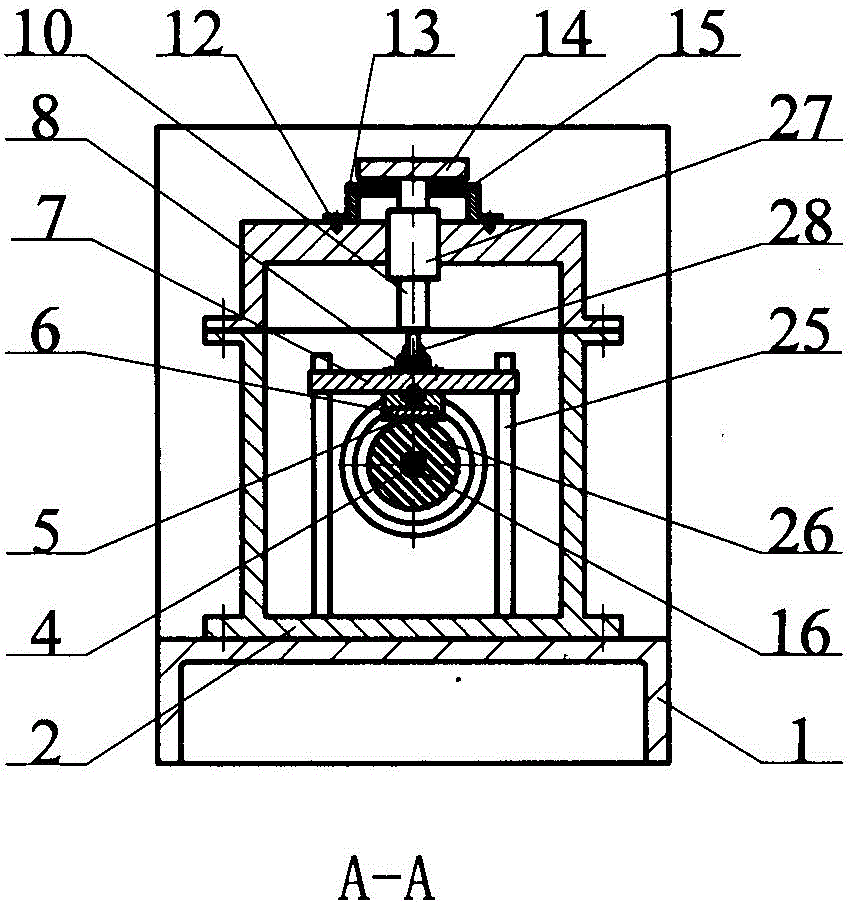

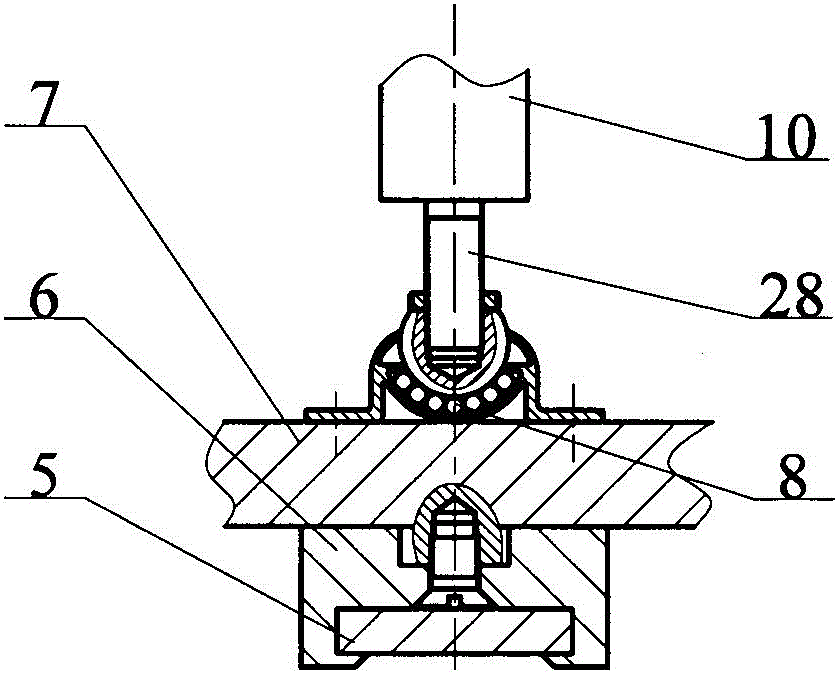

[0025] according to Figure 1~7Detailed description of the specific structure of the present invention, the wear gap adjustment type ring block friction and wear testing machine includes a support 1, a power and transmission mechanism fixed on the support 1 and a material box 2 provided with a loading mechanism and a testing mechanism, and a measurement components such as control circuits. Among them, the power and transmission mechanism adopt the basic structure of the applicant's previous patent "a ring block friction and wear testing machine with intelligent control of speed". It includes a main shaft 16 assembled in a headstock 23 , a drive shaft 20 with a torque sensor 17 fixed thereon, an output shaft 19 of a servo motor 18 and the like connected on the same axis by a coupling 21 . The main shaft 16 in this embodiment is installed in the main shaft box 23, and is respectively sealed by the bearing end cover 22 and the mechanical seal 24, so as to ensure the working accu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com