Mechanical clutch transmission device for combined seed and fertilizer drill

A technology of mechanical clutch and transmission device, applied in the direction of fertilization device, mechanical drive clutch, clutch, etc., can solve the problems of unstable work, easy lack of seedlings, inflexible ground wheel rotation, etc., to improve the quality of fertilization, prolong the service life, The effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

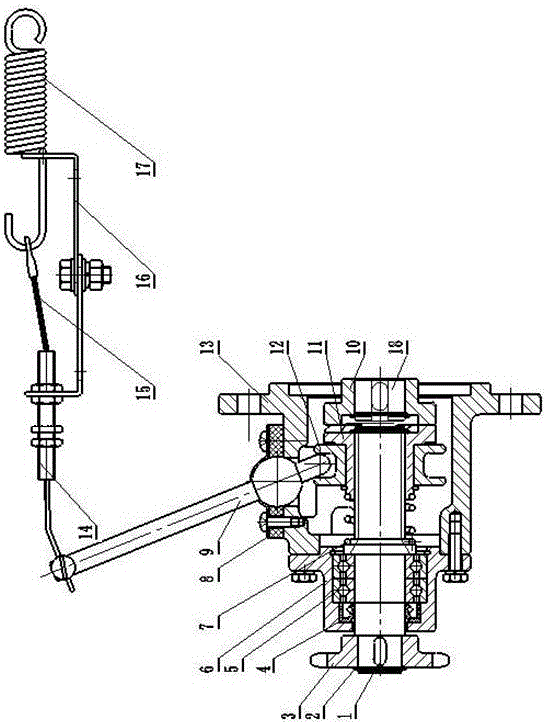

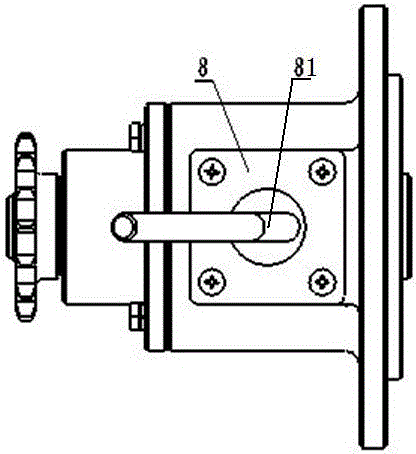

[0022] Such as figure 1 , 2 As shown, the clutch transmission device of the present invention includes a clutch flange 13, one end of the clutch flange 13 is fixed with a main transmission shaft 18 through a half clutch A10, the opposite end is fixed with a spline shaft 1 through a half clutch B11, and the opposite end surface is provided with a tooth The half-clutch A10 and half-clutch B11 form a jaw clutch, the spline shaft 1 is fixed with the clutch flange 13 through the cascade connection of the bearing 5 and the bearing seat 6, and the free end of the spline shaft 1 is fixed with a sprocket through the circlip 2 3. The body of the spline shaft 1 is provided with a compression spring 7 in the axial direction. The half clutch B11 is engaged with the half clutch A10 under the force of the compression spring 7. The half clutch B11 is provided with a fork ring 12 in the circumferential direction. The fork ring 12 Correspondingly, a fork lever 9 is arranged inside, and the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com