Novel load retaining valve structure for excavator

A load-holding valve and excavator technology, which is applied to multi-port valves, valve devices, mechanical equipment, etc., can solve the hidden safety hazards of workers, large leakage in the load-holding valve, and large settlement of excavator sticks and booms. and other problems to achieve the effect of improving stability and security and ensuring rapid response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

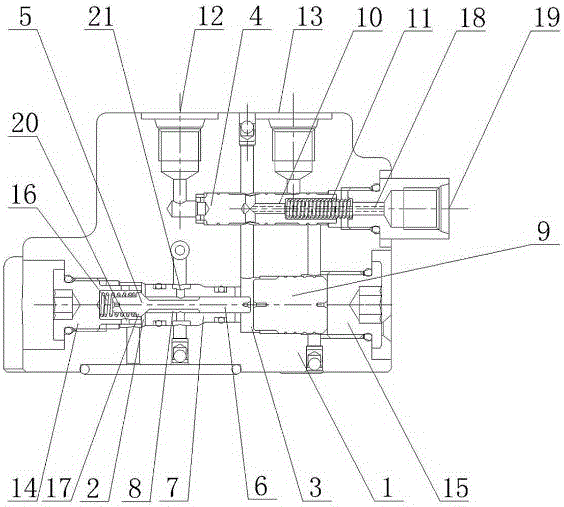

[0021] Such as figure 1 As shown, the present invention provides a new type of load holding valve structure for excavators, including a valve body 1 and an abdominal cavity arranged in the valve body 1. The abdominal cavity includes a first abdominal cavity 2 and a second abdominal cavity located on the right side of the first abdominal cavity 2. Abdominal cavity 3, the first abdominal cavity 2 communicates with the second abdominal cavity 3.

[0022] Such as figure 1 As shown, a cone valve core 5 and a valve sleeve 7 are sequentially arranged in the first abdominal cavity 2 from left to right. The right end of the cone spool 5 is horizontally provided with a push post 6, and the cone spool 5 is movable and located in the first abdominal cavity 2; a through cavity 8 is opened on the horizontal center axis of the valve sleeve 7, and the push post 6 runs through the cavity 8 And its length is longer than the length of the cavity 8.

[0023] The first overflow hole 20 is provi...

Embodiment 2

[0030] The present invention provides a new type of load holding valve structure for excavators, the structure is as described in Embodiment 1, the difference is that: figure 1 As shown, the valve body 1 is also provided with a first screw plug 14, which is located on the left side of the first abdominal cavity 2; the right end of the first screw plug 14 is provided with a damping spring 16, and the cone valve core 5 A boss 17 is provided, the left end of the cone valve core 5 passes through the damping spring 16 and is located in the first screw plug 14 , and the damping spring 16 is located between the boss 17 and the first screw plug 14 . When the plunger 9 pushes the cone valve core 5 to move to the left, the boss 17 compresses the damping spring 16 and at the same time the cone seal structure formed by the cone valve core 5 and the valve sleeve 7 is opened, at this time the high-pressure oil in the first abdominal cavity enters the valve sleeve 7 through cavity 8, and the...

Embodiment 3

[0032] The present invention provides a new cone sealing structure, the structure is as described in Embodiment 1, the difference is that: figure 1As shown, there is a discharge hole 18 on the central axis of the pilot valve core 10 ; the valve body 1 is also provided with an oil discharge port 19 , and the oil discharge port 19 communicates with the second abdominal cavity 3 through the overflow hole 18 . The discharge hole 18 can remove excess hydraulic oil accumulated and stored in the second abdominal cavity 3 to ensure the smooth movement of the plunger 9 .

[0033] The working principle of the present invention is as follows:

[0034] (1) When a load such as a boom is held, the first abdominal cavity 2 is a high-pressure chamber, and the hydraulic oil presses the cone valve core 5 onto the valve sleeve 7; this structure can control the leakage in the load holding valve to 2ml within / min.

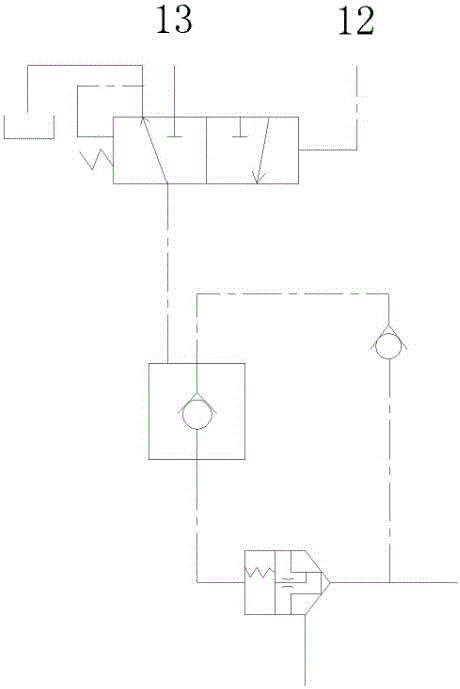

[0035] (2) The P1 oil inlet 12 is fed with pilot oil to push the pilot spool 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com