Offshore wind turbine barrel-in-barrel foundation

An offshore wind turbine and tube-in-tube technology, which is applied in infrastructure engineering, construction, etc., can solve the problems of high construction cost, long pile foundation length, and high requirements for deviation correction of engineering projects, so as to achieve firm and stable structure, convenient installation and construction, and reduced difficulty of deviation correction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

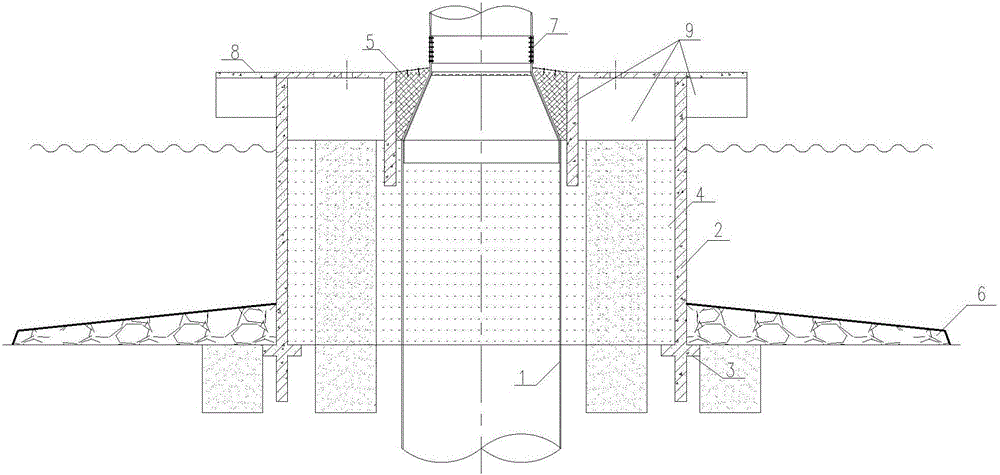

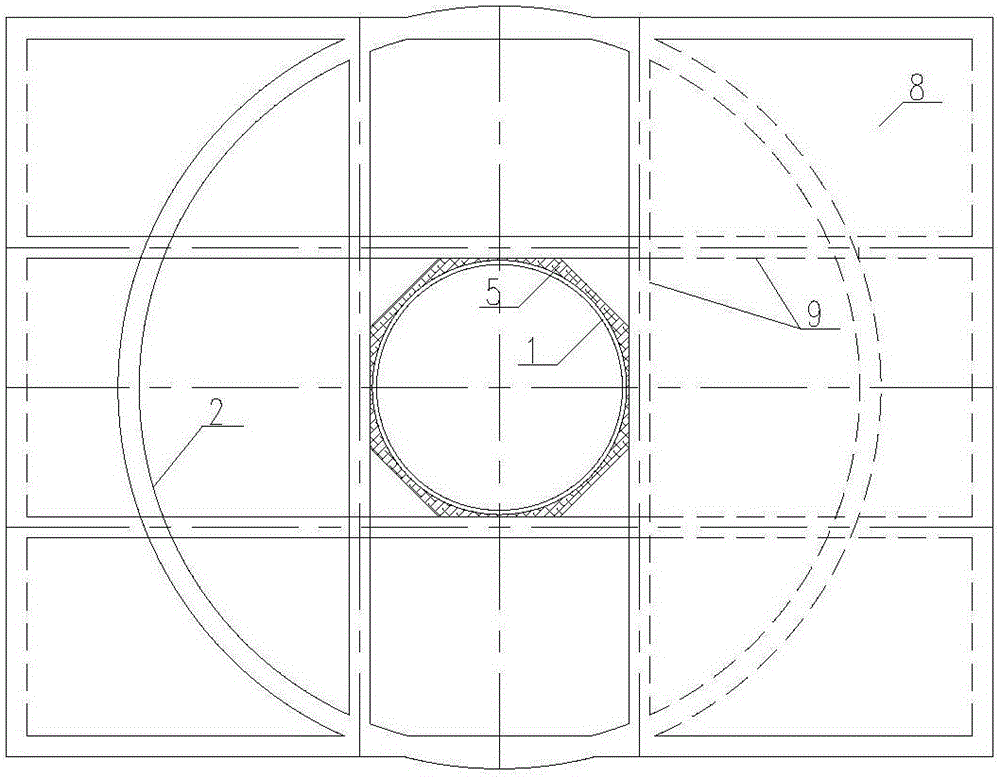

[0021] Such as figure 1 and figure 2 As shown, a foundation in the barrel of an offshore wind turbine, which includes an inner steel barrel 1, an outer reinforced concrete barrel 2 located on the outer periphery of the inner steel barrel 1, an outer barrel bottom plate 3 supported on the lower part of the outer reinforced concrete barrel 2, and an outer reinforced concrete barrel 3 located at the inner steel barrel 1 and The reinforcement filling 4 between the outer reinforced concrete cylinders 2, the damping material 5 between the cylinders, and the stone pressing 6 located on the bottom plate of the outer cylinder 3; the upper part of the inner steel cylinder 1 is connected with a steel cylinder flange 7, and the outer A construction maintenance platform 8 for construction installation and routine maintenance is installed on the top of the reinforced concrete cylinder 2 .

[0022] For the above-mentioned offshore wind turbine foundation, a load-bearing well grid beam 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com