Construction method for anchor rod for civil engineering

A technology of anchor bolt construction and civil engineering, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of low strength of anchor bolts, easy vibration of anchor bolts, cumbersome procedures, etc., and achieve the pull-out bearing capacity of anchor bolts High, good anchor hole stability, high anchor strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

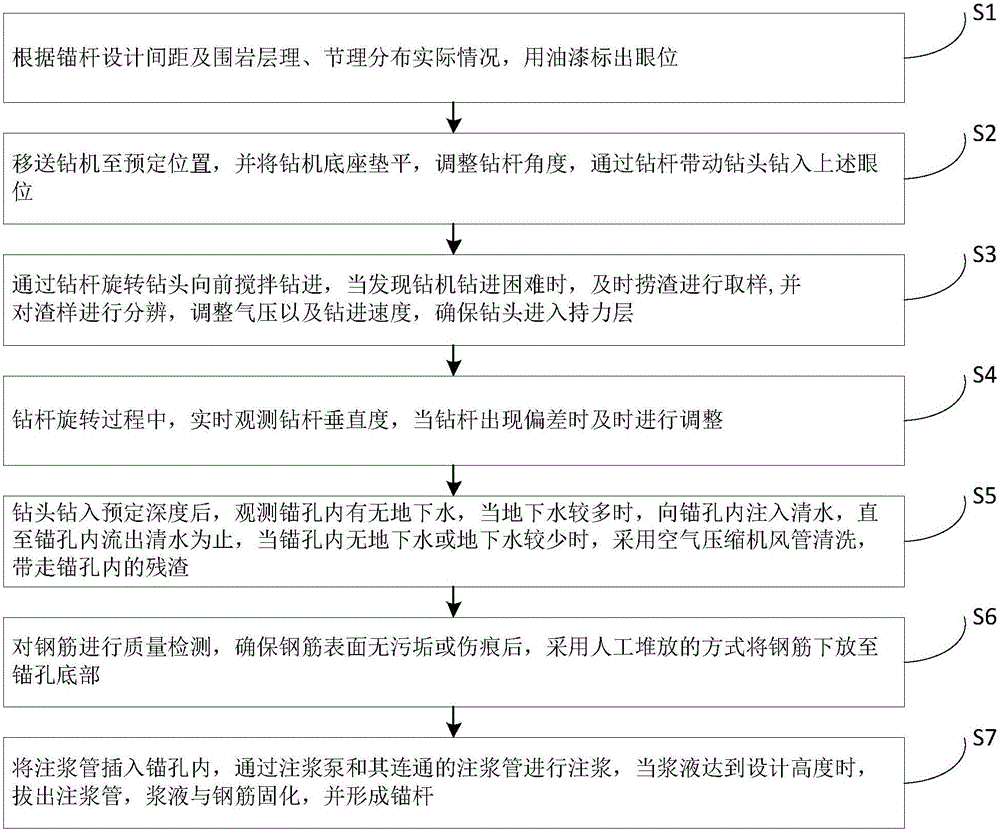

[0017] Such as figure 1 As shown, figure 1 It is a structural schematic diagram of an anchor rod construction method for civil engineering proposed by the present invention.

[0018] Reference figure 1 , The construction method of an anchor rod for civil engineering proposed by the present invention includes the following steps:

[0019] S1: According to the design spacing of bolts and the actual situation of surrounding rock bedding and joint distribution, mark the eye position with paint;

[0020] S2: Transfer the drill to a predetermined position, level the base of the drill, adjust the angle of the drill rod, and drive the drill bit into the above-mentioned eye position through the drill rod;

[0021] S3: Rotate the drill bit with the drill rod to stir and drill forward. When it is found that the drill is difficult to drill, remove the slag sample in time, distinguish the slag sample, adjust the air pressure and the drilling speed to ensure that the drill bit enters the holding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com