Electric heating alloy material with excellent high-temperature oxidation resistance and preparing method for material

A technology for resisting high temperature oxidation and electrothermal alloys, applied in the field of steel alloy materials, can solve the problems of high price and difficult to meet the service temperature, and achieve the effects of improving oxidation resistance, overcoming high temperature embrittlement, and enhancing high temperature corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In this embodiment, the composition and mass percentage of the electrothermal alloy material with excellent high-temperature oxidation resistance are as follows:

[0016] Cr21.23%

[0017] Al6.03%

[0018] Co1.33%

[0019] Zr0.14%

[0020] Rare earth Y0.04%

[0021] Nb0.43%

[0022] Mn0.23%

[0023] Si0.18%

[0024] C0.016%

[0025] N0.015%

[0026] S0.008%

[0027] P0.009%

[0028] Fe balance

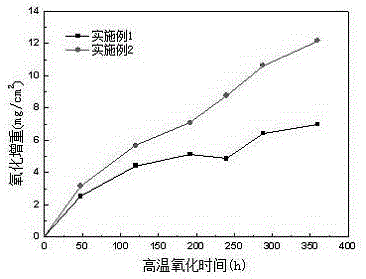

[0029] Vacuum induction smelting is adopted, after comprehensive measurement calculation and batching smelting, casting and molding, and then hot forging, hot rolling, recrystallization heat treatment, cold rolling and cold drawing, and finally obtained Zr and rare earth Y alloy elements with excellent high temperature resistance An electrothermal alloy material with oxidation performance, its oxidation weight gain is about 6.98mg / cm after isothermal oxidation at 1300°C for 360 hours 2 , and its oxidation weight gain curve follows a parabolic law.

Embodiment 2

[0031] In this embodiment, the electrothermal alloy material does not contain Zr and rare earth Y alloy elements, and the composition and weight percentage of the electrothermal alloy material are as follows:

[0032] Cr21.34%

[0033] Al5.98%

[0034] Co1.41%

[0035] Nb0.48%

[0036] Mn0.21%

[0037] Si0.19%

[0038] C0.016%

[0039] N0.017%

[0040] S0.009%

[0041] P0.007%

[0042] Fe balance

[0043] Vacuum induction smelting is adopted, after comprehensive measurement and batching smelting, casting and forming, and then hot forging, hot rolling, recrystallization heat treatment, cold rolling and cold drawing, and finally the electrothermal alloy material without Zr and rare earth Y alloy elements is obtained. , its oxidation weight gain is about 12.17mg / cm after isothermal oxidation at 1300°C for 360 hours 2 , and its oxidation weight gain curve also follows the parabolic law.

[0044] see figure 1 As shown, the oxidation weight gain of the electrothermal all...

Embodiment 3

[0046] In this embodiment, the composition and mass percentage of the electrothermal alloy material with excellent high-temperature oxidation resistance are as follows:

[0047] Cr22.65%

[0048] Al5.68%

[0049] Co0.6%

[0050] Zr0.18%

[0051] Rare earth Y0.04%

[0052] Nb0.12%

[0053] Mn0.33%

[0054] Si0.18%

[0055] C0.029%

[0056] N0.015%

[0057] S0.008%

[0058] P0.009%

[0059] Fe balance

[0060] Vacuum induction smelting is adopted. After comprehensive measurement calculation and batch smelting, casting is formed, and then hot forging, hot rolling, recrystallization heat treatment, cold rolling and cold drawing are finally obtained. It contains Zr and rare earth Y alloy elements with excellent high temperature resistance. An electrothermal alloy material with oxidation performance, its oxidation weight gain is about 7.39mg / cm after isothermal oxidation at 1300°C for 360 hours 2 , and its oxidation weight gain curve follows a parabolic law.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com