A kind of porous polyvinyl chloride foam ball and preparation method thereof

A technology of polyvinyl chloride foam and polyvinyl chloride, applied in chemical instruments and methods, and other chemical processes, can solve problems such as high cost, difficult control conditions, and low output, and achieve high porosity, economical preparation method, and development The effect of strong porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

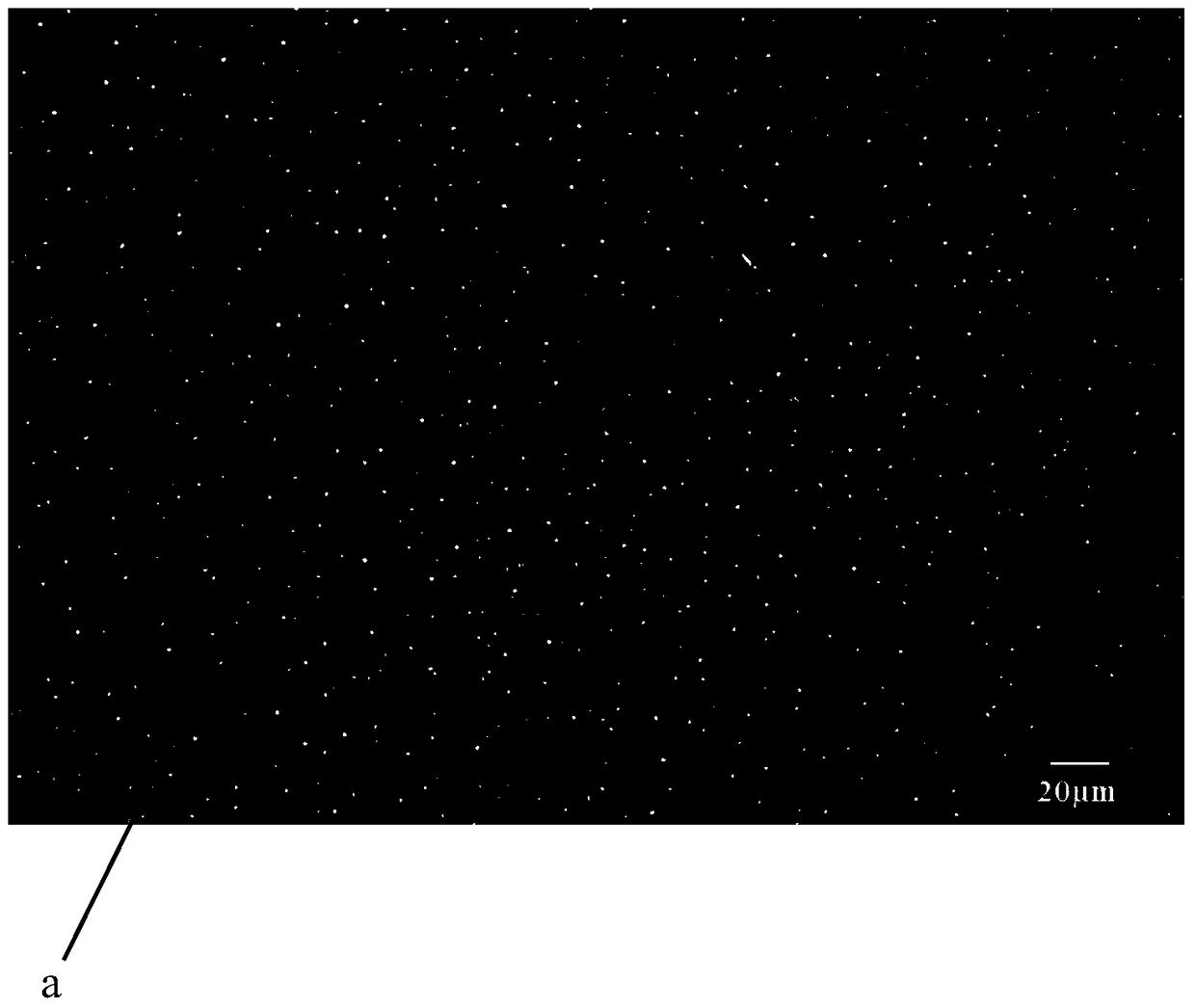

Embodiment 1

[0031] Weigh 1.5g of polyvinyl chloride powder and add it to 40mL of cyclohexanone, stir at room temperature for 30min until the polyvinyl chloride is completely dissolved to obtain a polyvinyl chloride solution; then put this polyvinyl chloride solution and 1g of potassium chloride crystal into a planetary Carry out ball milling in a ball mill; the quality of the ball milling medium used is 500g, and the particle size is 0.05-10mm; the speed of the ball mill is set at 200r / min, and the ball milling time is 20h; after the ball milling, take out the mixture of polyvinyl chloride solution and potassium chloride , drop it into the ethanol solution with a syringe with a volume of 10mL, and stir it with a magnetic stirrer at a stirring speed of 500r / min while adding it dropwise; then take it out and immerse it in distilled water to clean the porogen; It was taken out and drained at room temperature for 2 hours, then placed in a vacuum drying oven, and dried at room temperature for 2...

Embodiment 2

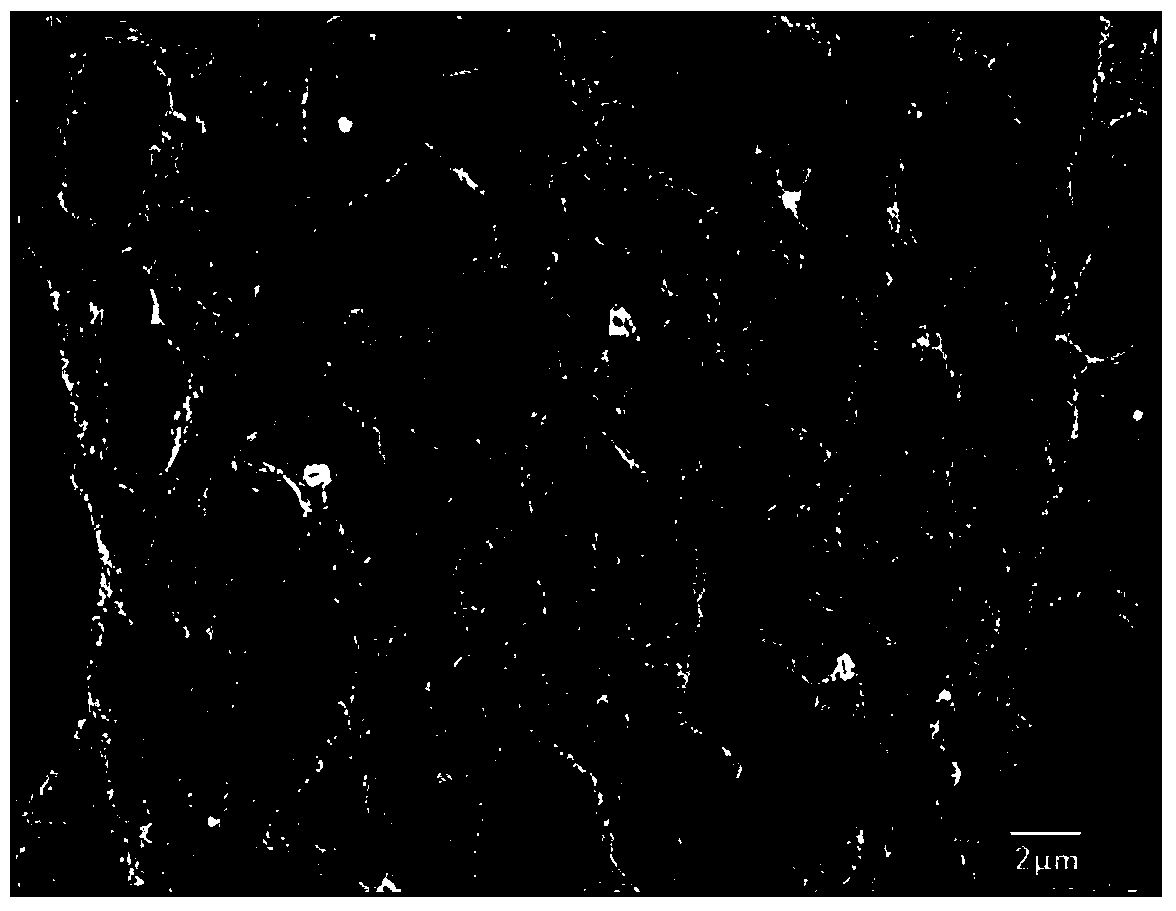

[0033]Weigh 9g of polyvinyl chloride powder and add it to 200mL of N,N-dimethylformamide (DMF), stir at room temperature for 30min until the polyvinyl chloride is completely dissolved to obtain a polyvinyl chloride solution; then mix this polyvinyl chloride solution with 120g Sodium chloride crystals are put into a stirring ball mill for ball milling; the quality of the ball milling medium used is 4000g, and the particle size is 0.05-10mm; the speed of the ball mill is set at 400r / min, and the ball milling time is 2h; Take out the mixture of solution and sodium chloride, add it dropwise into distilled water with a syringe with a volume of 50mL, and stir with a magnetic stirrer at the same time as adding dropwise, with a stirring speed of 100r / min; after cleaning the porogen, add It was taken out and drained at room temperature for 2 hours, then placed in a vacuum drying oven, and dried at 40° C. for 18 hours to obtain porous polyvinyl chloride foam balls of the present inventio...

Embodiment 3

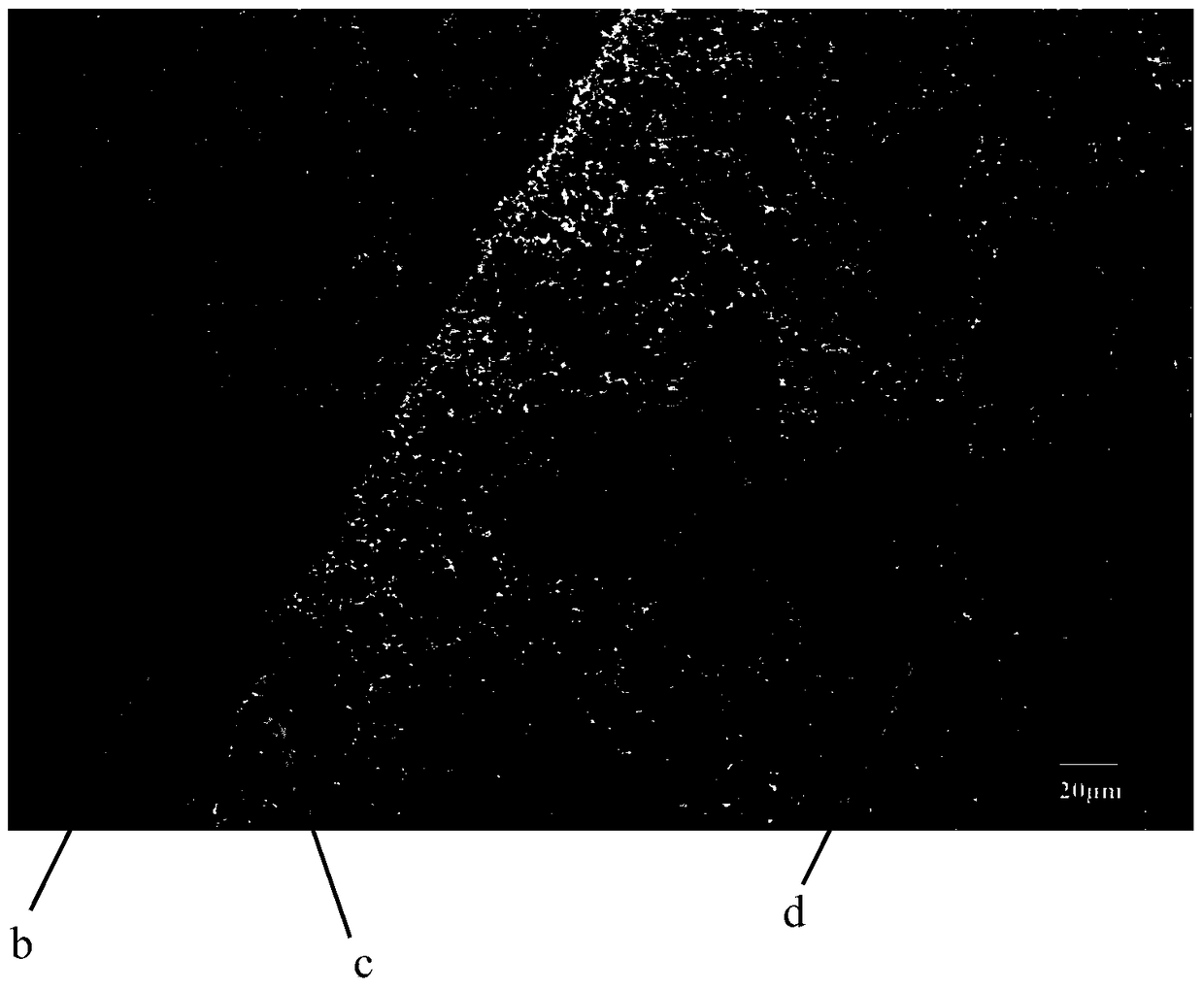

[0039] Weigh 6g of polyvinyl chloride pellets and add them to 70mL of cyclohexanone, stir at room temperature for 30min until the polyvinyl chloride is completely dissolved to obtain a polyvinyl chloride solution; then put the polyvinyl chloride solution and 14g of ammonium bicarbonate crystals into a stirring Carry out ball milling in a ball mill, the mass of the ball milling medium used is 1000g, the particle size is 0.05-10mm; the speed of the ball mill is set at 150r / min, and the ball milling time is 5h; after the ball milling, take out the mixture of polyvinyl chloride solution and ammonium bicarbonate , drop it into distilled water with a disposable dropper with a volume of 5mL, and stir it with a magnetic stirrer at the same time as the dropwise addition, and the stirring speed is 300r / min; after washing the porogen, take it out and drain it at room temperature for 2h , and then placed in a vacuum oven, dried at 50° C. for 10 h to obtain the porous polyvinyl chloride foa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com