Rice winery wastewater treatment system

A waste water treatment system and waste water technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems that cannot meet the treatment requirements of high-carbon and high-nitrogen waste water, and achieve the realization of Wastewater recycling, easy maintenance, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

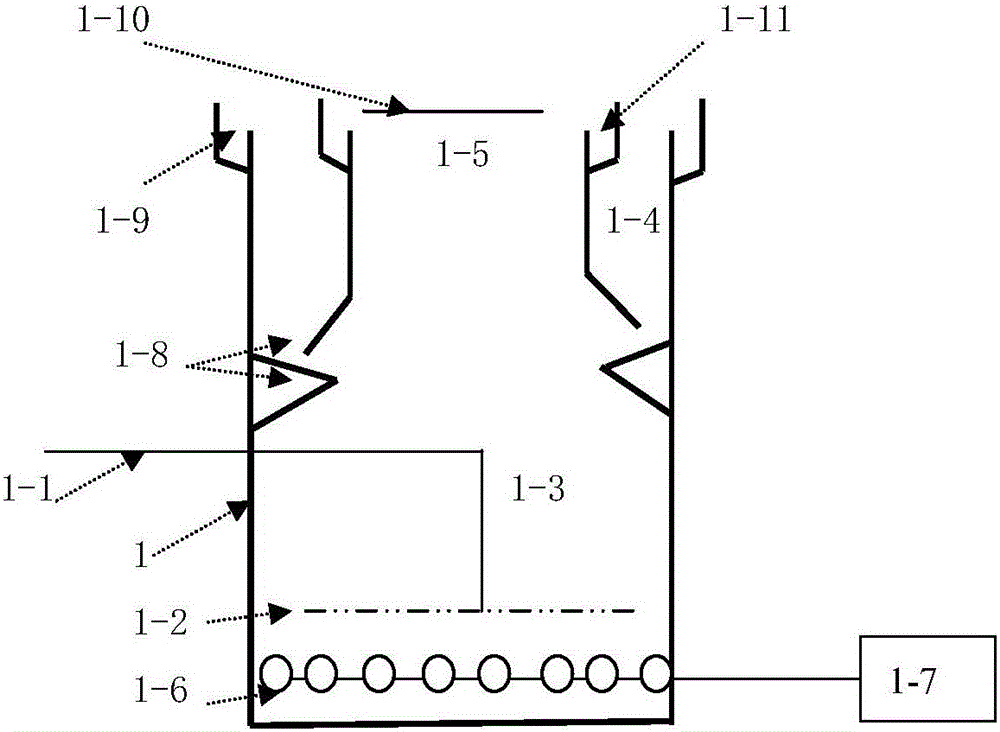

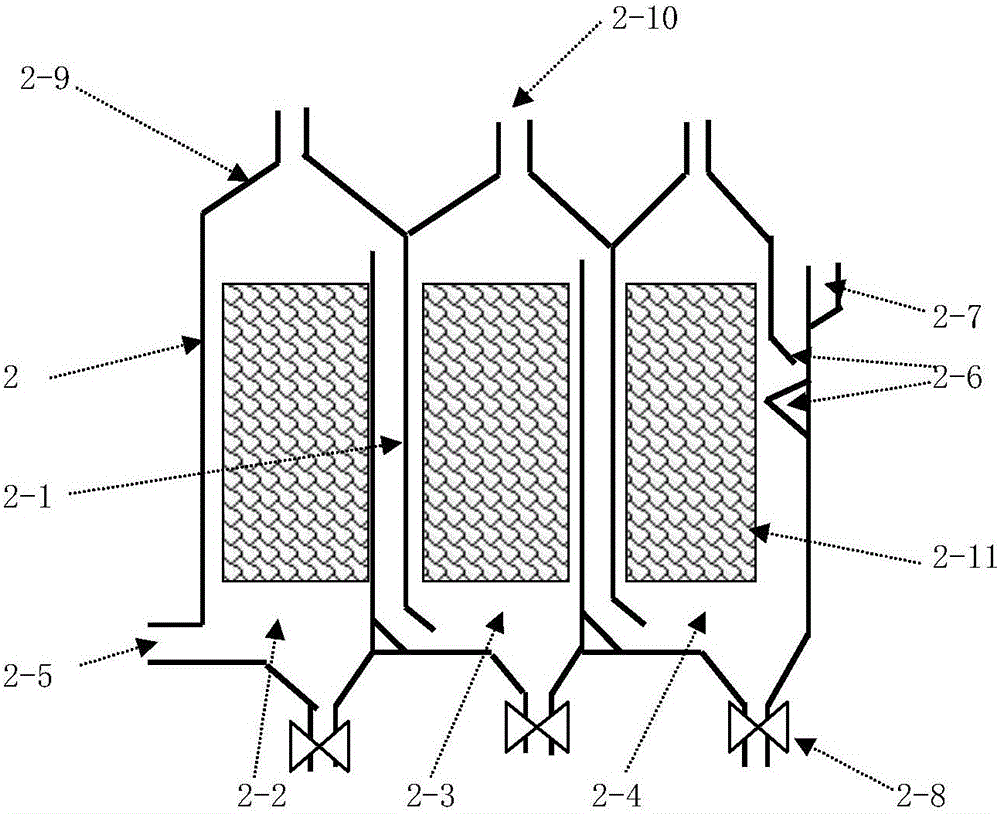

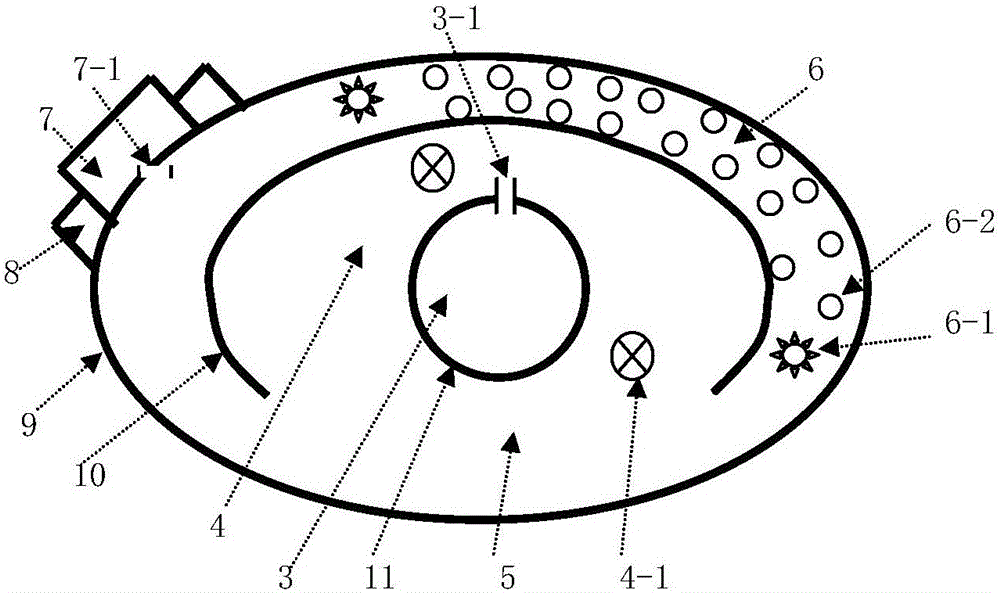

[0030] like Figure 1 to Figure 5 As shown in the figure, a wastewater treatment system of a rice winery of the present invention includes a wastewater regulating tank, an enhanced air flotation tank 1, a packed anoxic anaerobic reaction tank 2, a biochemical reaction circulation ditch and a clear water tank, a wastewater regulating tank, an enhanced air flotation tank 1, The packing type anoxic and anaerobic reaction tank 2, the biochemical reaction circulation ditch and the clear water tank are connected in sequence.

[0031] The wastewater regulating tank includes a water inlet pipe and a water outlet pipe, which are used for regulating the quality and quantity of the wastewater.

[0032] The intensified air flotation tank 1 includes a water inlet pipe 1-1 and a water outlet pipe for discharging the treated water, and the intensified air flotation tank consists of a mixing area 1-3 and a separation area in sequence from bottom to top; the separation area includes The water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com